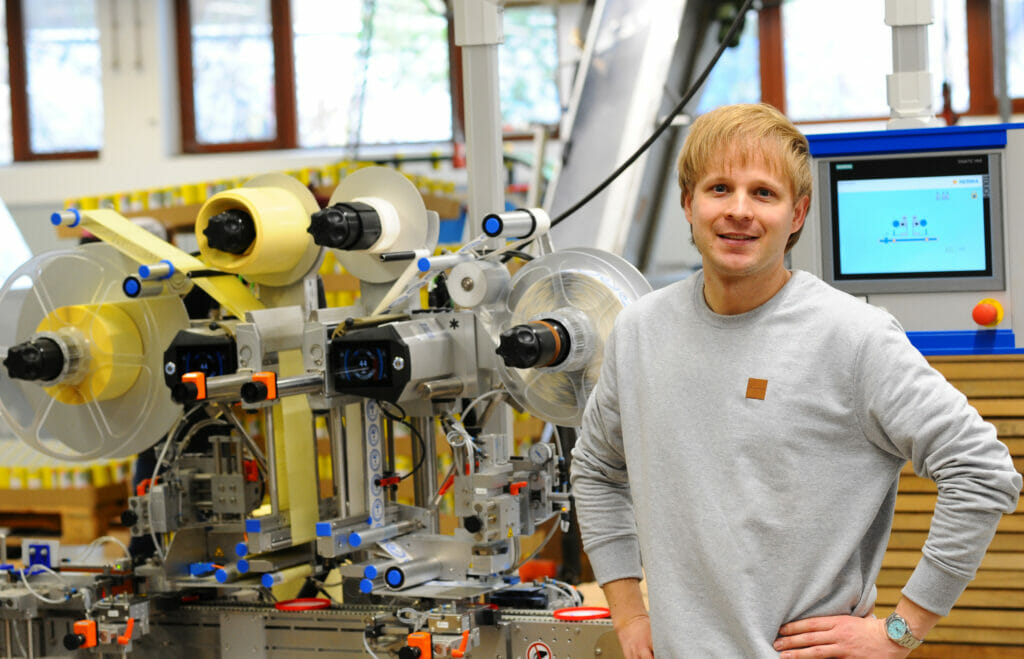

For special labelling of composite can lids for tobacco products, manufacturer J. M. Schmitt relies on a top-loading labeller from Herma. A special solution ensures that the label with warning notices fits perfectly and also places a cellulose pad in a precisely defined target circle.

Anyone who not only wants to place a label precisely in a lid, but also wants to In the next step, a much smaller second label must also be placed in a defined positionappreciates precise work. And, above all, the technology that makes it possible to reproduce this precision time and time again. This is another reason why the company J. M. Schmitt, which has specialised in round packaging for many industries for almost 100 years, has opted for labelling technology from Herma.

Extremely precise labelling is required, especially for the so-called composite cans for tobacco products - also because the legal requirements for this are strict. For example, the inside must be labelled a label with a mandatory warning be accommodated. This in itself is no easy task, as the plastic lids are recessed and very lightweight, making them susceptible to slipping on the conveyor belt. To make matters worse, that the tobacco manufacturer also wants to apply a humipad, a small cellulose pad, to the inside. The end consumer can moisten this later and thus keep the tobacco fresh.

"The Humipad must be positioned in the centre, exactly in the circular frame provided. The warning must not be covered under any circumstances, even the lines of the circle must not be touched. Strictly speaking, the packaging would then no longer be fit for sale."

Stefan Schmitt

Stop, lift, donate

J. M. Schmitt uses a special solution from Herma for this, the Obenauf 452E labeller. It was equipped with two Herma 500 labellers for this purpose. Coming from a steep bunker, the lids run through the machine on a conveyor belt. One labeller applies the label with the warning, the other applies the humipad, which is slightly larger than a 2-euro coin.

Because the lid has a recess, it is initially gripped from the side by two centring jaws. They stop the lid and lift it slightly at the same time, controlled by compressed air, so that no abrasion is caused by the conveyor belt running underneath. The label is then removed with a suction pad, which has previously picked up the label from the moving release edge, labelled into the lid from above. Finally, the jaws retract and the labelled lid continues to run.

The Humipads are almost three millimetres thick. This is why Herma has installed special deflection rollers in the labeller. On the second labeller, the lid is also centred again and stopped briefly so that another suction pad can be applied. can place the pad exactly without it even touching the precisely defined target frame. J. M. Schmitt sometimes labels 25,000 to 30,000 lids per day on this system.

The fact that Herma labellers are not only precise, but also quickly available thanks to their modular design, has also helped the company from Bad Neuenahr - Ahrweiler. Because when the flood came in the summer of 2021, J. M. Schmitt was literally on the brink. The muddy flood waters of the Ahr flowed through the production halls with a wave almost two metres high. In an incredible feat of strength, Schmitt recalls, the owner family and their 50 or so employees spent weeks shovelling the sludge out of the production area.

However, many specialised machines could no longer be saved. It was vital for the company to get production up and running again. "Although there were material shortages everywhere at the time, Herma was able to supply the necessary labellers within a very short space of time," says Schmitt. That The flood of the century, of all things, was the technological leap in labelling has triggeredStefan Schmitt would have liked to have spared his company this, however.

Source: Herma

Herma - More news

HERMA presents sustainable labelling solutions without compromise

Herma Managing Director Sven Schneller announces retirement for 2026

That was the cycle & circle sustainability tour 2025

Packaging Valley invites you to Sustainability Day 2025 - registration started