Solvay introduces a new ultra-high barrier coating for more sustainable pharmaceutical blister films. It combines a high water vapour barrier with good thermoformability for the design of thinner and more sustainable blister films.

Speciality materials manufacturer Solvay has introduced a new coating solution, Diofan Ultra736 polyvinylidene chloride (PVDC), with an ultra-high water vapour barrier. the production of pharmaceutical blister films with a reduced carbon footprint is possible. The aqueous dispersion is fluorine-free, fulfils applicable regulations for direct contact with pharmaceuticals and supports the design of more sustainable films with thinner coatings.

„Consumers and regulators are calling on the packaging industry to step up efforts to reduce the carbon footprint of their products, and one of the most effective ways to do this is through smaller and lighter packaging. Our new Diofan Ultra736 coating solution can help packaging film manufacturers achieve superior barrier properties with thinner structures, significantly reducing the carbon footprint of blister films.“

Federico Baruffi, Global Marketing Manager, Packaging, Solvay Specialty Polymers

Pharmaceutical blister films with Diofan PVDC coating are widely used for the protective packaging of sensitive solid medicines. They are also used in the packaging of delicatessen products and similar foodstuffs. They can be applied to both plastic and paper substrates and are often the preferred coating solution due to the combination of their good water vapour and oxygen barrier.

Diofan Ultra736 has been specifically developed to maximise the water vapour barrier of the PVDC coating without compromising its high oxygen barrier, chemical resistance or transparency. It can also be easily thermoformed, This allows for smaller packs with a higher tablet density compared to conventional products.

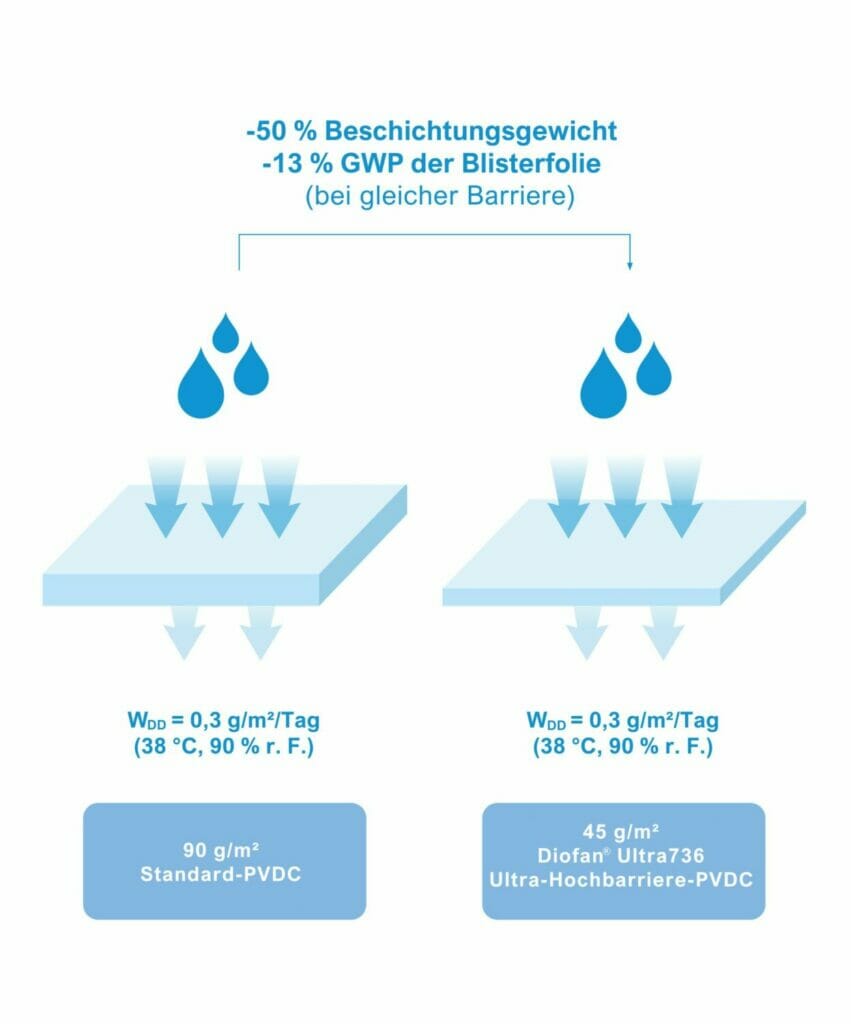

Thanks to its ultra-high barrier performance, Diofan Ultra736 to thinner coatings without any loss of functionality than would be possible with conventional PVDC films, for example. For duplex barrier structures in particular, Diofan Ultra736 has shown that the number of base layers required can be halved while maintaining the same water vapour barrier. This solution can help to reduce the overall carbon footprint of finished blister film structures. by up to 13 per cent.

Source: Solvay

Pharma - More news

Limburger Packaging Group integrates Müller & Bauer

Sharp invests massively in expanding packaging capacities

ACG launches sustainable blister solution on the market

Sustainable tubes for cosmetics and pharmaceuticals