Höfelmeyer Waagen GmbH has developed a new type of weighing station for IBCs. It consists of a stainless steel base frame and one or more weighing platforms with tilting devices. The containers are simply and safely positioned on the station using a pallet truck or forklift. Gas pressure springs tilt the containers automatically as they become empty. This optimises residual emptying.

The systems correspond to the Protection class IP69K and are in favour of „Intermediate Bulk Container“ with a capacity of up to 1,000 litres. Depending on the requirements, the liquid media are either removed or dosed manually or automatically controlled. The weighing stations can be integrated into higher-level system processes via the Ethernet, Profibus or Profinet interfaces.

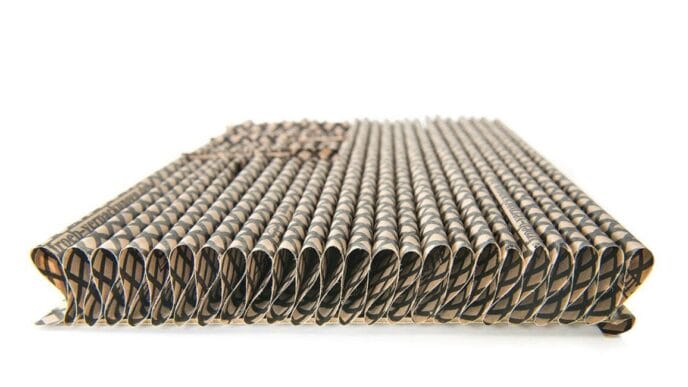

Weighing stations are particularly suitable for viscous products

These are intended Weighing stations for typical applications in which IBCs are used, such as for temporary storage or for Handling and Dosing of liquid substances in industries such as food, Chemicals, pharmaceuticals or cosmetics. They are available as single, double and triple stations. A larger number of storage spaces can be realised by combining them. There are also storage areas for additional IBCs underneath the rack.

Höfelmeyer emphasises that the weighing stations are particularly suitable for containers with viscous products. In addition to the hydrostatic emptying of the containers via the Floor outlet the use of pumps is possible. The stations can also be combined with mixers and agitators.

Höfelmeyer Waagen GmbH continues to pursue this goal with the new weighing station, Measurement technology offers for the entire factory, from goods receipt to delivery. For over 30 years, the company from Georgsmarienhütte and other branches in Germany has been developing Compact scales, Modular weighing systems and customised Special applications.