In order to work even more closely with brands and other partners in the value chain, Holmen Iggesund has created the new Future Packaging department. The aim of this collaborative approach is to fulfil the customer needs of the future.

The new Future Packaging department is made up of dedicated Specialists with a broad range of expertise, for example in segments such as cosmetics, food and electronics. If required, further expertise in areas such as tool processing, punching and barriers can also be brought in.

„We see that brand companies are looking for new types of packaging. They want their packaging to be more sustainable. One option is to replace fossil-based materials such as plastics. We want to help with this. To achieve this, we need to be closer to the brands and understand what they do - and we also need to understand the entire value chain in order to offer the brands innovative solutions that fulfil their needs. If the brand, machine manufacturers, material suppliers and designers work together, the time to market can be shortened enormously.“

Hein van den Reek, Director Future Packaging at Holmen Iggesund.

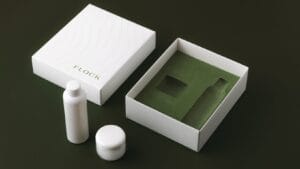

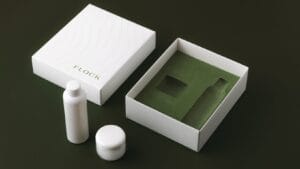

To show brand companies, How this collaborative approach can speed up the process, Holmen Iggesund has already developed prototype solutions together with external partners. In 2021, Conic, a mouldable wood-based premium packaging solution for the cosmetics industry, was created. And now Holmen Iggesund and its partners have developed the Choco chocolate box.

Made entirely from renewable materials, the chocolate box consists of an outer box and an insert tray with various cavities at different heights for individual chocolates. The box was developed in collaboration with the processor Goerner Formpack, the tool manufacturer HP Molded Fibre Advanced Tooling Solutions and the investor group FutureLab & Partners. Invercote Creato 400 cardboard from Holmen Iggesund is used for the outer box. The inlay tray is produced by Goerner Formpack using their wet moulding process. Imould from Holmen Iggesund is used, a food-safe material made from long and short primary fibres.

„We all need packaging, but we need to think about what kind of packaging we use, where it comes from and what happens to it at the end of its life, and we think it should be reused. Our main motivation for the project was to develop a tray made from cellulose for direct food contact so that single-use plastics are no longer used in the customer's packaging departments.“

Elisabeth Goerner, Managing Director Goerner Formpack

With another important future aspect in mind, Holmen Iggesund brought the tool manufacturer HP on board for the Choco box project. HP uses 3D printing to manufacture the wet mould tool, which Goerner Formpack used to produce its insert tray for the box of chocolates. „3D printing is a new form of mould production,“ says van den Reek. „That's important, because it can be more cost-effective and sustainable than conventional tools.“ HP is focused on developing technologies that accelerate the transition from single-use plastics to sustainable solutions such as moulded fibre materials.

„The change in the packaging material sector is coming our way. Fibre packaging will experience rapid growth in the coming years as the use of plastics declines. And the major players in the pulp and paper industry, such as Holmen Iggesund, must work with the premium brands to enable the transition from plastic packaging to new solutions.“

Dick Huizinga, Head of Business Development and Sales EMEA at HP Molded Fibre Advanced Tooling Solutions

The new Future Packaging department uses prototypes such as Conic and the Choco box to demonstrate how solutions can be developed in collaboration that are can be used in many different industries can.

Source: Holmen Iggesund

Holmen Iggesund - More news

Holmen Iggesund relies on Future Packaging

These are the best cardboard packaging 2021