Direct printing on hollow packaging such as cans, bottles and tubes offers a number of advantages over adhesive labels and shrink sleeves. The designs are robust, have a high colour intensity and enable packaging made from mono-material - not to be underestimated in terms of recyclability. Digital printing can also be used to produce customised packaging.

Modern systems for hollow body printing are no longer limited to cylindrical bodies. They can print a variety of shapes and materials without distortion. Digital printing is gaining ground in this area of application. The additional costs incurred for digitally printed containers due to the more expensive printing inks are no longer an obstacle for many brand owners. This is because, if you want to realise corresponding marketing concepts or cross-media components such as Augmented Reality or Virtual Reality simply no alternative to this.

As with other types of packaging, more and more variants and constantly changing subjects are being created, for which separate printing forms have to be produced in screen, flexo, gravure or offset printing. Not so with digital printing: here, even Samples or proofs at the touch of a button can be produced. This also eliminates the costs of overproduction and warehousing.

Customised designs for the can

Like other manufacturers of systems for hollow container printing, Polytype had been looking forward to the interpack and Metpack trade fairs, where it presented a new digital printing machine for aluminium or steel cylinders for the first time together with its sister company Mall+Herlan. Like Polytype, Mall+Herlan belongs to the WIFAG-Polytype Holding and manufactures complete production lines for metal cans and tubes. Anilox printing machines, in which colour is transferred by means of flexible clichés, have been integrated into these lines to date.

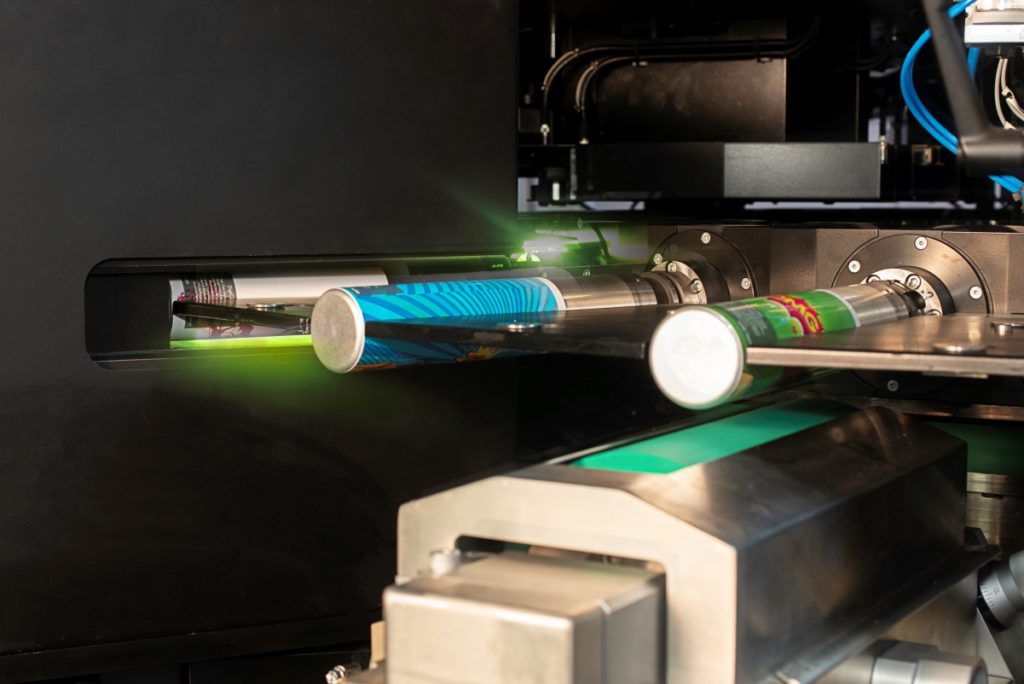

The new „DigiCan“ for small and medium batch sizes also comes from Polytype. It utilises the company's own UV inkjet digital technology „CALMAR“, which is also used in other machine types. For example, for printing plastic cups, tubes and bottles. Like these, DigiCan can also be used in line or stand-alone.

„With CALMAR, the customer gets everything from a single source directly from Polytype. „This ranges from electronics and software to printing systems, automation and ink supply through to customer service.“ Daniel Kohlenbrenner, Sales Manager Plastic Tubes & Containers Polytype AG

With a resolution of 600 dpi, photorealistic motifs can also be produced and there is no changeover time when changing motifs. Cylindrical bodies with a diameter of 35 to 66 millimetres and a height of 50 to 215 millimetres can be processed with a maximum output of 7,200 pieces per hour.

Plastic and glass

For some time now, glass as a packaging material has increasingly become the focus of attention for decorators. „We would have liked to present our direct printing process on glass bottles at interpack,“ says Ingrid Reuschl, Head of Public Relations at Krones AG, a manufacturer of systems for the beverage and liquid food industry. When interpack was cancelled, the company designed an online showroom for its DecoType„ digital printing solution“. The inkjet machine was developed by the Krones company Dekron GmbH in Kelkheim. They are available in three performance levels. At the top is the „Performance“ model with up to 36,000 containers per hour.

All offer a resolution of 360 dpi and can be process cylindrical bodies made of PET, rPET and glass (print height 190 millimetres). The drop-on-demand UV inkjet process used can also be used for Targeted printing of reliefs and structures and other areas that are difficult or impossible to label. Printing is carried out with low-migration ink specially developed for the DecoType in W+CMYK, with spot colours available as an option. A „clear ink“, also known as digital varnish, can provide a haptic effect (digital embossing). Extensive print image inspection technology is also part of the scope of services. The printed PET containers are fully recyclable, as certified by the Association of Plastic Recyclers (APR) in 2019.

Flexible platform concept for hollow body decoration

A slightly different approach to the decoration of hollow bodies is taken at Koenig & Bauer's Kammann GmbH from Löhne approach. „Our speciality is the Handling of the bodies to be printed“, says Managing Director Matthias Graf. „How to guide even complex-shaped objects under a printing unit in such a way that a consistent and distortion-free print image is created.“ Kammann has been doing this successfully since the 1950s with screen printing on plastic and glass. There should have been a presentation of a new product family at this year's glasstec, but this event has also been postponed until 2021.

„Our new HS machines for thermoplastic screen printing on glass are faster and more precise than their predecessors,“ says Graf. „Up to 36,000 bottles per hour can be printed with up to eight colours.“ In addition to the third generation of its embossing station for hot-foil finishing of hollow containers, Kammann is also introducing a Mobile embossing module which can be integrated into existing screen printing machines.

Kammann has recently developed a solution for inkjet digital printing. Matthias Graf: „The process works without contact over distances of up to several centimetres. Raised areas or hollows can be printed in the same way as surfaces - even shapes that would not be printable in analogue.“ Kammann relies on a hexachrome colour space with high resolution. Hybrid solutions in combination with hot foil technology are also possible thanks to Kammann's platform concept. „In digital printing, we also offer our own solutions for the entire prepress workflow focussed on hollow container printing,“ says Graf.

The market is developing

There are many other solutions for digital direct printing on hollow bodies on the market. For example, the D240 UV inkjet printing system from Eislingen-based container printing specialist Hinterkopf, which was launched in 2014 as the world's first digital printing machine for cylindrical hollow bodies made of metal or plastic. This was followed this year by the enhanced version D240.2, while a comparable system is the Michelangelo KX48P from Italian manufacturer Martinenghi, which specialises in industrial printing machines. Koenig & Bauer MetalPrint, on the other hand, has a market-leading analogue 10-colour anilox printing system for the mass production of two-piece beverage cans in its range, the CS MetalCan. In particular the Potential of digital printing, providers seem to agree, will crystallise even more strongly in the coming years. The constantly advancing development of printing technology will also contribute to this.