Particularly high hygiene requirements apply to the production and processing of food. igus offers companies lubrication-free and maintenance-free linear guides. The company is now presenting the drylin W linear slide in hygienic design.

The highest hygiene requirements therefore apply to all systems and machine components, such as linear guides. The first choice of material is stainless steel; all other materials must be manufactured in accordance with EU or FDA regulations. Lubricated components must be specially encapsulated and the greases and oils must fulfil special guidelines.

The linear guides from igus are used here. This is because linear plain bearings or plain bearing foils made of high-performance plastic are used at the bearing points. Thanks to incorporated solid lubricants, external lubrication can be dispensed with. be cleaned. As a result, the drylin W linear guides are not only clean, but also maintenance-free and environmentally friendly. As the igus high-performance polymers are tribologically optimised - i.e. optimised for friction and wear - they also impress with their long service life and less micro-abrasion compared to commercially available plastics.

Solution for the food industry

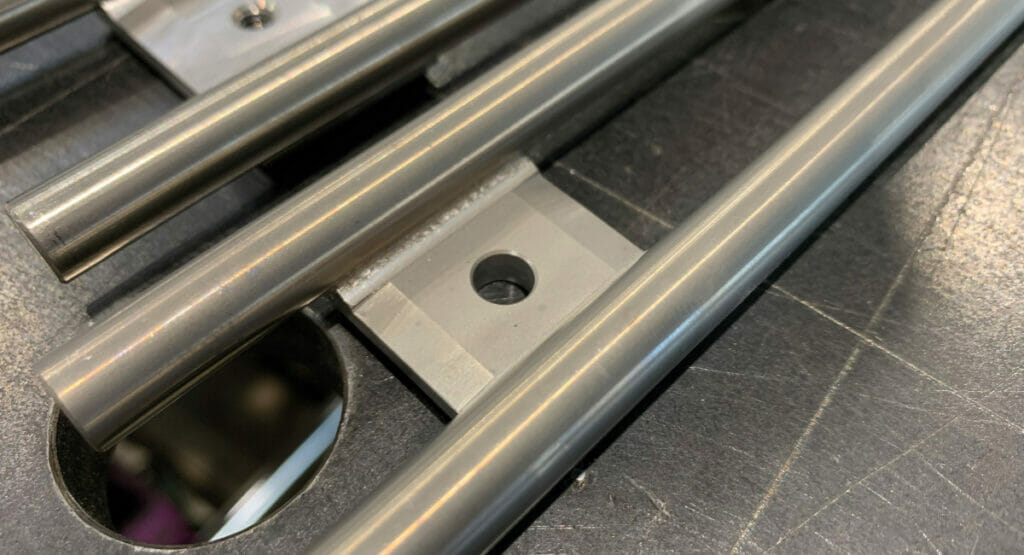

Especially for use in the food industry, the company offers the drylin W modular system, which is dimensionally identical to recirculating ball bearing guides and was developed based on the hygienic design guidelines of the European Hygienic Engineering & Design Group (EHEDG). In doing so, igus relies on Carriages and guide rails made of resistant stainless steel as well as FDA and EU10/2011-compliant plain bearing elements made of a high-conductivity plastic specially developed for food contact.

Corrosion resistance plays a particularly important role in the cleaning process. The design of the components used is also crucial for thorough and easy cleaning. This is because even the smallest moisture-collecting dead angle can lead to contamination of the end product.

„For this reason, more and more customers want an optimised design in addition to the same dimensions as recirculating ball bearing slides. This is why we have now joined the EHEDG, an association of equipment suppliers to the food industry, universities, research institutes and health authorities. The aim is to consistently develop a drylin W polymer linear slide that consistently fulfils the hygienic design requirements. Most hygienic design solutions to date have been based on a complete enclosure. With our flushable polymer slide, we are taking a completely new approach and focussing on an open design.“

Mira Heiligenhaus, drylin product developer at igus

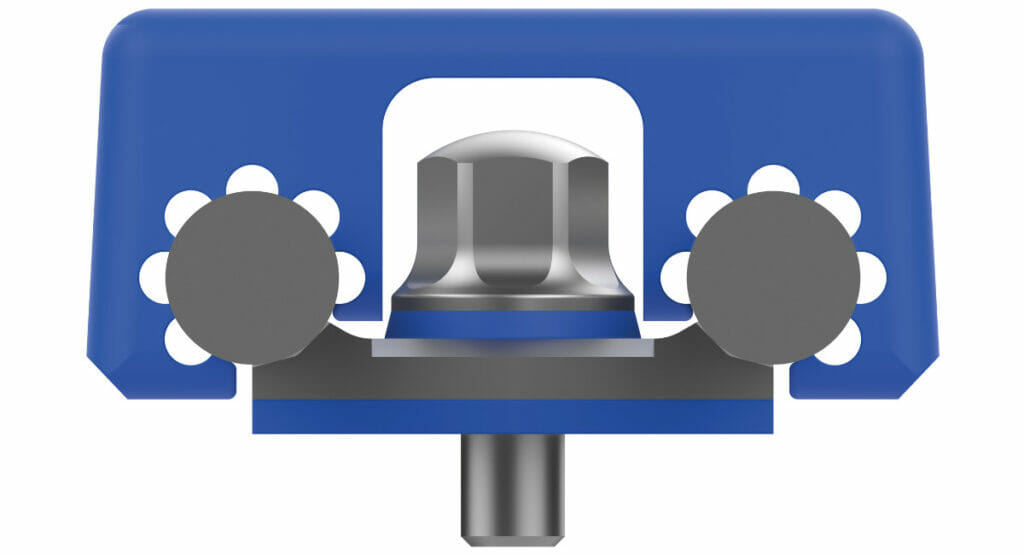

A gap-free design, an iglidur high-performance plastic and stainless steel ensure a hygienic linear guide. The new drylin W linear slide is the First sliding carriage made entirely of FDA-approved plastic. The linear rail is made of corrosion-resistant, high-alloy stainless steel. A high surface quality prevents dirt from adhering and makes cleaning easier.

„The main challenge was to create a Gap-free design so that the slide can be completely rinsed and liquids can run off unhindered.“ The company therefore relies on bevelled edges, hygienic screws and extra-large rinsing grooves on the sides and on the bearing surface. The floor seal protects the space under the rail from contamination and prevents food or chemical residues from settling. The shafts are also sealed to protect gaps from residues.

„On the one hand, FDA-compliant sealing material is used here. On the other hand, sealing can also be realised using circumferential welded or soldered seams. The support elements are brazed with nickel using the inert gas brazing process. The brazing and high-temperature soldering process enables a firm, material-locking connection. Thanks to this optimised design, the guide can be cleaned easily, thoroughly and in a matter of seconds. The water drips off directly everywhere.“

Mira Heiligenhaus

„Our aim is to create a to bring a certified linear guide system to the market as a series product in accordance with hygienic design guidelines“, explains Mira Heiligenhaus. „Currently, certification is still a challenge, as moving parts have narrow gaps due to their function and therefore existing designs do not fulfil the current requirements. For this reason, we want to develop a solution together with the EHEDG in Germany and our customers. Our design study is intended to trigger a discussion among our customers and create a basis for further ideas and products.“

The linear guide with the new T15/T20 carriage offers users a solution that ensures optimum rinsability and therefore greater safety in the food industry. The The blue colour of the plastic slide also makes it easy to detect. The operation itself is low-vibration and low-noise thanks to the optimised sliding properties. Whether for bakery and confectionery, fruit and vegetable processing or sausage production, linear technology from igus promises significant optimisation of production in all areas of food technology.

Source: igus

More news about packaging machines

Krones celebrates 75 years of company history

Traffic lights prevent bottlenecks

Confectionery: Flavour alone is no longer enough

Mettler-Toledo shows inspection solutions in Düsseldorf