Whether in automated workpiece handling, palletising systems in logistics or in adjustable assembly devices: Designers who require robust linear axes for automated adjustment tasks often waste valuable time integrating motors and controllers. To solve this challenge, igus has developed drylin SLX-8060 - a new ready-to-install linear system with an electric dryspin spindle drive.

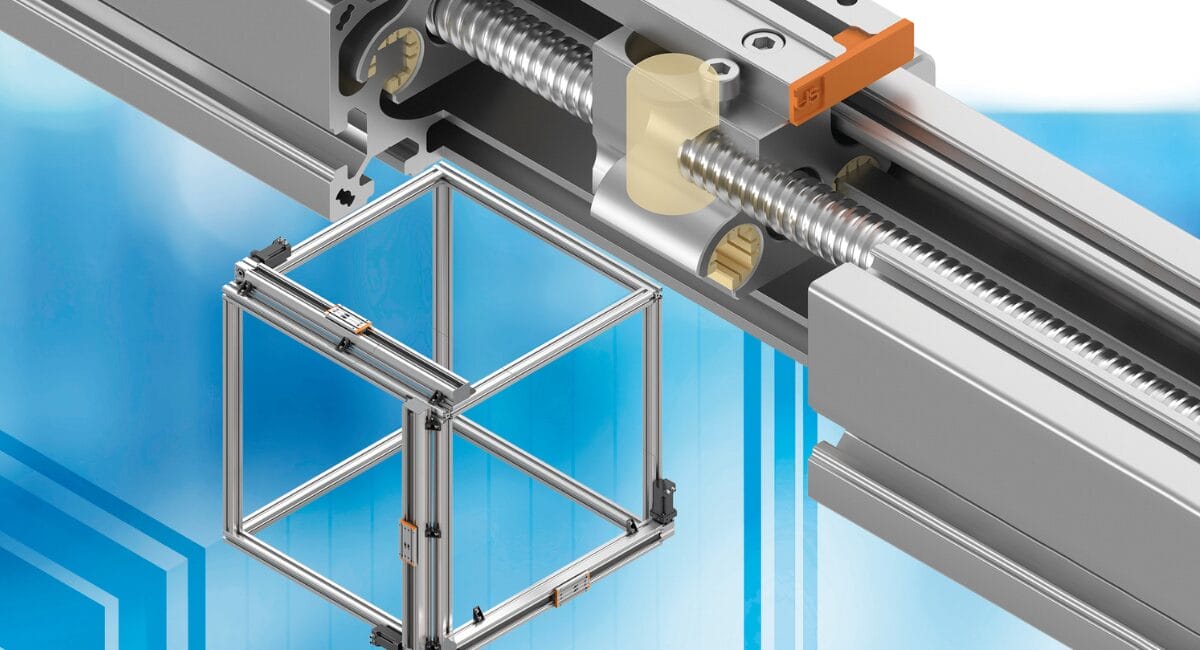

With a load capacity of up to 600 kilograms, it is particularly suitable for applications in logistics, robotics and production cells in packaging technology. The drylin SLX-8060 linear axis is based on a corrosion-resistant, clear anodised aluminium high profile with an integrated linear guide from the drylin W series in size 16. It is driven by dryspin thread technology, which can be operated manually or electrically.

„We launched the ZLX, a new generation of linear axes with a toothed belt drive, back in 2024 and received positive feedback from design engineers around the world. They have confirmed that they save design time with the ready-to-install solution. We have therefore decided to expand our portfolio with a spindle drive version of the linear axis to offer design engineers even more flexibility.“

Michael Hornung, Product Manager drylin Linear and Drive Technology at igus

Depending on the size, the new linear axis can be Pick up loads of up to 600 kilograms and is versatile - whether as a single axle or for portal superstructures.

Quick installation on aluminium construction profiles

This is how the new drylin SLX linear axles are designed, that users save assembly time. They can be mounted on aluminium construction profiles without drilling holes. Thanks to the new design, the axle also fits seamlessly into classic mechanical engineering profiles and thus offers a uniform appearance. Large grooves enable Quick integration of accessories such as sensor mounts or protective devices. „On request, we can also supply the linear axes ready to install with motors and controllers - including stepper, EC/BLDC and DC motors.“ Alternatively, motors from other manufacturers can also be connected. „For manual operation, the SLX can be equipped with operating elements ranging from angular gearboxes to safety handwheels from the modular drive technology system,“ says Michael Hornung.

Lubrication-free reduces maintenance costs and increases reliability

The drylin SLX linear axes also help designers to increase the reliability of their application and reduce maintenance costs. This is because a key advantage of the linear systems is that they are lubrication-free. The slide and spindle run over linear slide foils and threaded nuts made of high-performance plastic and therefore do not require lubrication with oil or grease. Microscopically small solid lubricants ensure low-friction dry running. The design is therefore more resistant to dirt and enables low-noise operation.

„This not only eliminates the need for expensive maintenance work for lubrication. The SLX linear axis is also Less susceptible to malfunctions by a paste formation of grease, dust and dirt and therefore more fail-safe,“ says Hornung. „In addition, three completely enclosed sides offer increased protection against the ingress of dirt particles.“ The principle of „sliding instead of rolling“ facilitates the use of aluminium and plastic, makes the design lighter and maximises performance.

Long-term tests passed

igus has also developed the new linear axes of the SLX series subjected to long-term tests in the company's own 4,000 square metre test laboratory. They prove the durability with 113,232 double strokes over 23,590 operating hours. The asymmetric dryspin thread technology extends the service life of the axle by around 30 per cent and increases efficiency through optimised material ratios. Size 16 gives the drylin SLX a higher load capacity of up to 1250 N axial and 5000 N radial and a maximum stroke length of 1000 mm.

Sourceigus GmbH