For a long time, moving parts in packaging machines were only made of metal. But as early as 1964, an engineer from Cologne had the idea of developing products made of low-wear high-performance polymers for the movement in machines. Today they are called motion plastics, and igus is the world's leading manufacturer. The company also produces using 3D printing in order to be able to deliver prototypes, small series and special parts even faster.

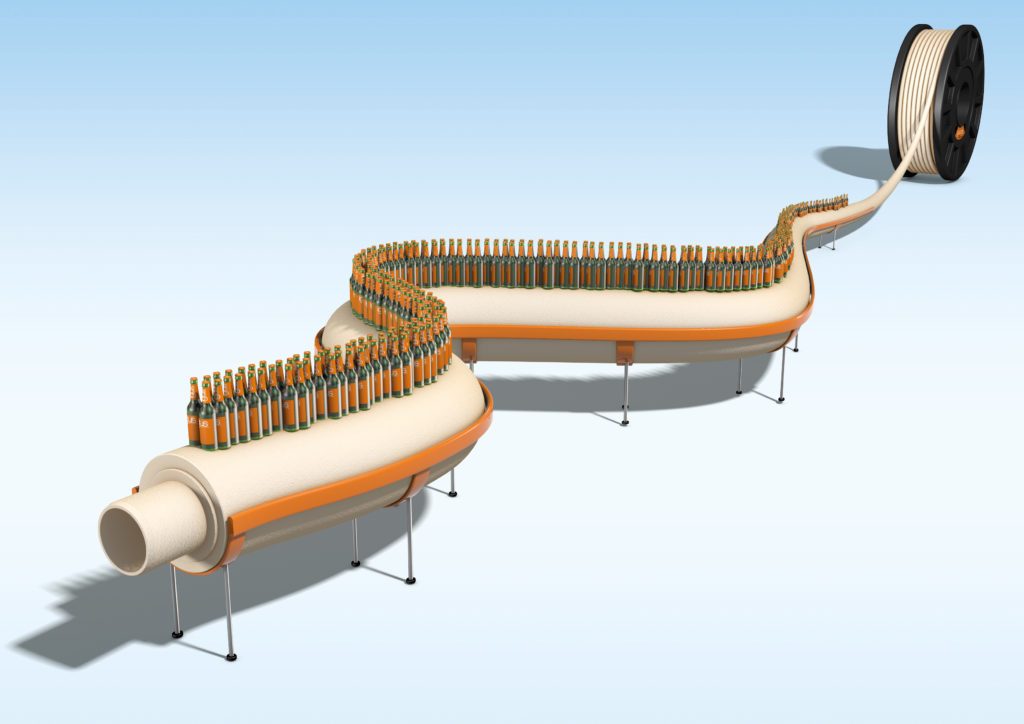

The lubricant-free plastic plain bearings, energy chain systems and special parts made from semi-finished products and 3D printing are also in demand in the beverage and packaging industry. They are exclusively Made from high-performance plastics developed in-house standard plastics are not used at igus.

The owner-managed company has been operating for more than 50 years. own polymer research and is constantly developing new plastic compounds. Self-lubricating iglidur high-performance plastics have also been available for 3D printers since 2015. igus uses them to additively manufacture wear parts such as gear wheels, gear racks, plain bearings, threaded nuts, sliding elements, rollers and complex special parts.

Prototypes and small batches can also be produced in a short time. The range of polymers includes Speciality filaments for 3D printing in the strand deposition process (FDM/FFF) and high-performance plastics for selective laser sintering (SLS).

High-performance plastics for moving applications

Last year alone, igus delivered 120,000 additively manufactured components. The Cologne-based company's globally available 3D printing service is particularly interesting for internationally active companies that frequently face logistical challenges. for the rapid procurement of identical additively manufactured parts stand. Design engineers can use the service to order, test and use the same lubrication-free and low-maintenance parts across borders without having to put up with long delivery processes.

In the summer, igus further increased its 3D printing capacities with two more SLS printers in the USA and an additional system in China and now delivers prototypes, small series and special parts even faster. Two further SLS printers are also planned for the main site in Cologne.

Tribo filaments up to 50 times more abrasion-resistant

The printed components can be delivered regionally in just a few days. The cost benefits are obvious: machine downtimes can be reduced thanks to the rapid delivery of spare parts, development costs can be cut thanks to faster functional prototypes and delivery costs can be reduced thanks to local production.

"Tests have shown that the wear resistance of the additively manufactured parts is absolutely comparable to injection moulded parts. Our tribologically optimised filaments are up to 50 times more abrasion-resistant than conventional 3D printing materials." Tom Krause, Head of the Additive Manufacturing division at igus

Metal grippers that place the lid on cream jars, for example, are usually limited to a single format. It therefore often takes weeks to produce the right gripper for a product change. 85 per cent cheaper and 70 per cent faster is possible with robust plastic grippers made of igus Tribo filaments, which come directly from the 3D printer and are up to seven times lighter than conventional metal grippers due to the material.

Tribo filaments such as iglidur I150 have another advantage: they comply with EU Regulation 10/2011 for food contact. The SLS material iglidur I6 is also compliant with FDA requirements. Thanks to these certifications, customers can also use the materials for printing Use special parts for moving applications that come into direct contact with food, drinks or even cosmetics. stand.

3D printing service 2.0

Wear parts can be ordered online from igus - via the 3D printing service. Customers select a printing material that is best suited to their application. By entering individual environmental parameters, the 3D printing service shows them the optimum iglidur material online. Orientation offers an online tool that is based on the latest results from the company's own test laboratory. - the largest in the industry.

Mass finishing and black colouring of SLS parts can now also be selected at the click of a mouse. Prices and delivery times are displayed directly to the user so that they can order or enquire about the component immediately. In the new version of the 3D printing service tool, there is now also the option of Check the feasibility of 3D models immediately online.