As the saying goes: „First impressions count. And the last one lasts forever.“ The company Illert Etiketten in Hanau can confirm this. Labels make a decisive contribution to the sales process. The effect is optimised when the consumer buys.

Which product the consumer „falls for“ depends on many factors of the respective labels. Colouring, typography, graphic representations or special surfaces can inspire consumers. It is important that the buyer immediately recognises „their“ supplier from the complete presentation.

This can Managing Director Maximilian Illert, Managing Director of Illert GmbH & Co. KG, based in Hanau, can only confirm this. From the label specialist's point of view, label printing has developed into one of the most flexible printing processes in recent decades.

It is also possible to cover the entire range of packaging printing by using a wide variety of printing and finishing processes in one system. The enormous development of flexographic printing in particular has led to a high-quality and cost-effective process.

[infotext]The company Illert GmbH & Co. KG in Hanau/Steinheim can look back on an eventful history. Since Founded in 1856 As the chromolithographic art institute Illert & Ewald, labels still play a relevant role today. Initially, cigar boxes and banderoles were printed in colour, later it was tin labels, chocolate wrappers, aluminium foil labels using the rotogravure process and adhesive labels on rolls. Today, the portfolio includes shrink sleeve packaging, adhesive labels, opaque multi-layer labels and special solutions.Speciality shrink sleeves

Shrink sleeve labels are printed shrink films that adapt to the shape of the product at certain temperatures. Illert produces shrink sleeves entirely according to customer specifications and in a wide variety of designs. This type of label is ideal for promotions, special sales, special decorations, advertising campaigns, closure protection, etc. Economical and decorative solution and. In addition, high-quality processing such as embossing with holographic properties or special colours can turn the respective product into a premium product.

Finally, shrink sleeves take special products „into safekeeping“. Shrink sleeves are becoming increasingly important in the decoration of products. Their biggest advantage: almost any product can be decorated with 360-degree graphics and/or images can be customised. Shrink sleeves, and this is where the creative department of the manufacturer or print shop comes in, can be adapted to a wide variety of shapes. Ultimately, the entire packaging can also be protected against tampering.

Shrink sleeve labels are certainly challenging conventional wet adhesive or self-adhesive labels for their place in the labelling market. Experts estimate the global share of this type of label to be up to 20 per cent and rising. The materials used are generally PVC, PET-G, PLA and OPS.

The only fly in the ointmentThe volatility of the oil price. This can lead to problems with the procurement of materials, or more precisely Cost increases, come. For this reason, developers at material suppliers are rapidly researching thinner, multi-layer films and films with completely new property profiles. Ultimately, this also benefits the environment.

Finishing and function test

The company refines this type of label from printing to slitting/winding to sleeve bonding. Depending on the customer's requirements, the shrink sleeve labels are turned into Roll or cut-off goods processed. As a functional test, the printed shrink sleeves are shrunk with pinpoint accuracy in our own shrink tunnel using water vapour. The temperature has to be right, because different materials always require different treatment, i.e. a different dwell time in the tunnel.

„We have already been able to convince several customers of the practicality of our products with test runs. Our creative department also played a significant role in this.“

Maximilian Illert

The printing of shrink sleeve packaging has developed into a relevant business segment for the company. Due to the sometimes considerable shrinkage capacity of the films, even the most extreme shapes can be securely wrapped. Whether thin-walled or thicker material, whether plastic or glass, the shrinks can do it all. Anyone who does not want to keep printed containers in stock for economic reasons can use this labelling process for Just-in-time deliveries utilise.

Multi-layer labels

With multi-layer labels, i.e. labels with at least two or more layers, another important pillar has been created. Illert has currently specialised in two layers of labels concentrated. How such a label is structured, what content it should have and what it should look like depends on the customer's requirements and the task. In principle, the top layer covers the layer below and only reveals it once the top layer has been removed. In this way, product promotions can be specifically printed with special offers.

At the end of the promotion, the top label is simply peeled off and the normal label reappears. And the promotional product becomes a normal sales product again. The company's previous experience with multi-layer labels indicates a High acceptance within the customer base there.

Intensive demand from the chemical, cosmetics and DIY product sectors clearly demonstrates this. The opaque version is used for this type of label and its use for promotional purposes. Information for the buyer is printed on the front and back, and a competition may be printed on the reverse.

labelled with a promotional label. (Image: Illert GmbH & Co. KG)

Paper labels still the order of the day

Despite the preference for printed films, the time-honoured paper labels are far from obsolete at Illert. According to the motto „there is always gluing“ the company offers all kinds of paper labels. Whether printed or unprinted, thermal or glossy paper and many more - whatever the customer wants. The variety of paper choices and corresponding surfaces leave nothing to be desired.

Investments for even better label quality

At Illert, everything is UV flexographic printing printed. The Nilpeter FA 3300 printing press may be getting a little long in the tooth, but thanks to proactive maintenance, constant care and the timely replacement of parts at risk of failure, it continues to perform well. The compact flexo label press is proving to be an ideal solution for both large and small print runs. Productive and economical solution.

The sleeve technology, which enables both conventional flexographic printing plates and the use of flexographic printing sleeves, contributes to the extremely fast changeover. The machine also has a cold foil stamping unit for finishing. All printing and die-cutting processes are monitored and optimised via the Press Management Center.

An Omet Varyflex VF 670 F1 flexographic printing press was added to the printing press fleet. This was the first machine of its kind to be installed and commissioned in Germany. Films up to twelve micrometres thick, such as BOPP, OPP, PET, PE, PVC, OPS, shrink sleeves and cardboard as well as aluminium and cardboard up to 300 g/m² in medium format can be printed and processed with this machine at up to 200 metres per minute.

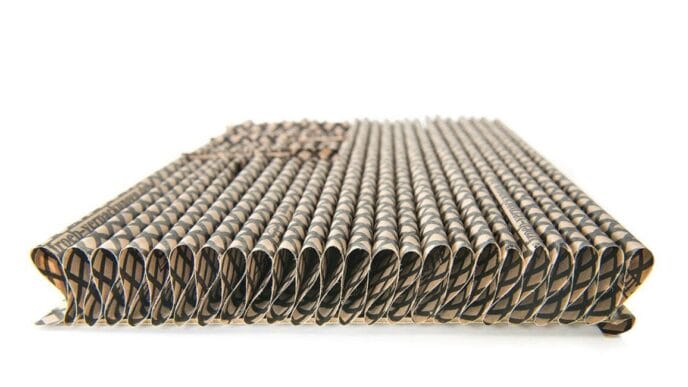

In keeping with this, a Film roll slitting and winding machine from the French manufacturer DCM ATN. A Freschi cutter was also purchased. At the same time, a sleeve gluing machine from DCM ATN was added. This enables shrink sleeves to be produced with tear-open thread, longitudinal perforation and two different double-chamber versions. Thanks to the rotary cutting process, shrink sleeves can even be produced with cross perforation and a so-called T-perforation.

Smart Factory at a glance

The topic of Digitalisation and networking. In addition to the machines in operation, which are equipped with sensors for remote maintenance, internal networking is to be increasingly expanded. This means access to every machine, bringing the topic of the smart factory ever closer. The various components that provide manufacturing services in the factory are to be intelligently networked with each other.

While external networking is centred around the Communication with other smart factories, the internal networking integrates all components of the production process. Although the topic is still a long way off, the first steps have already been taken.