The companies Erca - France, Gasti - Schwäbisch Hall and Hassia - Ranstadt, which are integrated under the aegis of Industria Macchine Automatiche IMA S.p.A. and focus on food and dairy products, stood out both with their product range and the special nature of their market cultivation.

After the takeover by the Majority shareholder Thomas Becker At the end of 2018, the measures introduced are taking effect. New structures were introduced. The products of the individual companies were realigned to the given market requirements, with application-orientation taking top priority, and the sales and service area was expanded and developed.

In the meantime, the three companies of the IMA Dairy & Food Group, Hamba was integrated into Hassia as an independent company with profit responsibility, its own brand identity and its own sales organisation. Overlaps in terms of product range are minimal and are balanced out by activities in very different markets. IMA Dairy & Food Holding was relocated from Stutensee to Ranstadt.

pj: Mr Becker, what actually prompted IMA S.p.A. to sell its stake in Dairy & Food?

Thomas Becker: In principle, the companies within the Group were optimally positioned. However, it was not possible to fully utilise the dormant potential of the individual IMA DAIRY & FOOD companies. Fully leverage capabilities and opportunities.

This is because the planned path to profitability and the associated Reorganisation was extremely difficult after the takeover of the Oystar Group. For IMA, the new target market with almost exclusively customised machines did not really fit into the planned concept.

pj: What prompted you to join this company?

Thomas Becker: Well, I know the industry and I know what can be achieved by focussing on the actual strengths. I also find the entrepreneurial challenge extremely demanding. Namely, aligning companies in such a way that they develop into market leaders in their markets. This also means that we have to change and correct structures.

For example, we have worked with IMA Dairy & Food UK a new sales and service company founded. Hamba was integrated with its portfolio at Hassia Verpackungsmaschinen, as its high-performance filling and sealing machines complement Hassia's machine programme well. Gasti concentrates on its proven machine programme of filling and sealing machines. IMA Dairy & Food Holding was relocated from Stutensee to Ranstadt. To the 1 January 2020, IMA Dairy & Food Russia is the latest new company to be founded. at the start.

pj: Does your joining IMA Dairy & Food also involve personnel changes, i.e. job cuts?

Thomas Becker: As already mentioned, we have separated Hamba and Gasti and integrated Hamba into Hassia. Some employees have left, but most of them stayed and were taken over. At the same time, we have already taken on some new employees in order to meet the growing market requirements.

This also applies to all IMA Dairy & Food companies, such as Erca, Gasti, Hassia, IMA Dairy & Food UK, IMA Dairy & Food USA and the newly established company in Russia. We also have a good relationship with the owner family Vacchi and can therefore also capitalise on synergy effects.

pj: What strategies do you want to use to lead the individual companies to success?

Thomas Becker: First of all, I have to say that the companies sales of their products a lot of room for improvement. At Hassia alone, numerous ideas and concepts for new or optimised machines lay dormant. After I joined the company, I looked through old documents and was surprised at what the people around the then founder Karl Klein had already thought up and put down on paper in the 1950s. That was forward-looking. For example, the First blister pack created.

But back to the question. At Hassia, machines from Hamba were integrated and the production of FFS / moulding, filling and closing machines and stickpack machines was expanded to include sachet machines, FS / filling and closing machines for prefabricated cups and bottles. Gasti also manufactures FS / filling and closing machines at a high level, albeit in a different performance range.

Erca in France has added rotary-type machines for prefabricated cups and trays and the newly developed ‚EFS‘ filling and sealing machine to its portfolio. All of these companies have strong market position in the product areas with significant growth opportunities.

pj: What role does the extended aseptic centre play in the interaction between the companies?

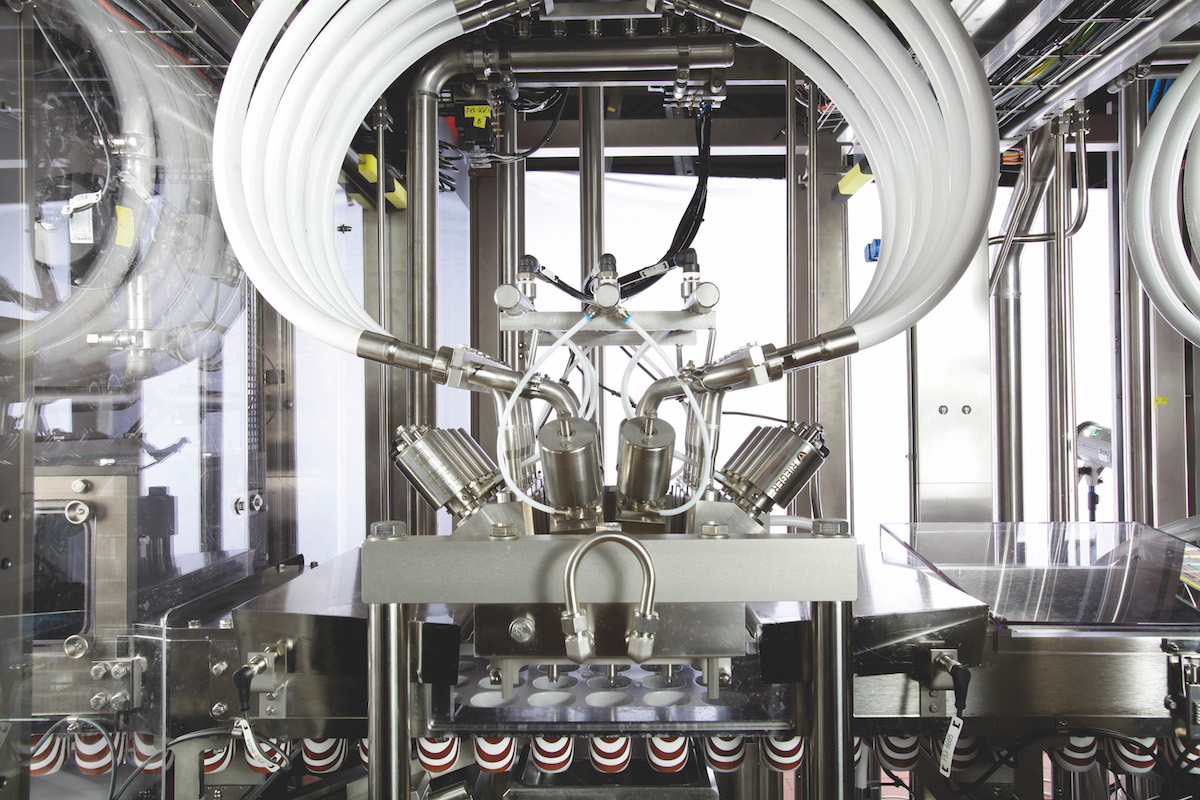

Thomas Becker: Consumers want a relatively Long shelf life for sensitive products; but without chemical preservatives. We realise this with our Aseptic centre in Ranstadt. Here we offer our customers a complete solution from the idea and production of a packaging system through to acceptance and final installation on site.

In the laboratory, microorganisms may be used up to Risk group II can be worked on. All the necessary equipment is available to carry out microbiological tests. We have the appropriate specialists on board for this task. The aseptics team is also available for validation, emergencies, inspection or optimisation of existing systems.

pj: What other measures are taken by the Aseptic Centre?

Thomas Becker: A key point is the Routine quality control of all hygienic machines before their delivery, the so-called FAT (Factory Acceptance Test). The factory acceptance test is followed by the SAT (Site Acceptance Test) at the customer's premises. We also provide on-site customer support.

Our experts there determine the killing rate of disinfection processes using microbiological stress tests. This is like a kind of Sterilisation TÜV. The test is extremely important as it proves commercial sterility. For this purpose, test stands are set up in the laboratory and microbiological test series are carried out.

pj: What structures will you introduce in sales and service?

Thomas Becker: With the launch of the branch IMA Dairy & Food UK we have started to establish local sales and service. IMA Dairy & Food USA we have committed to our line. Starting in January 2020 IMA Dairy & Food Russia. The preparations for this are almost complete. The branches are responsible for sales and service. There are also plans for a number of expansions. But these are just ideas at the moment.

pj: According to a study by management consultants Deloitte, the DMI Digital Maturity Index, 25 per cent of respondents achieve an EBIT increase of 15 - 30 per cent due to digitalisation. How far has digitalisation progressed at IMA?

Thomas Becker: Our machines have long been designed to collect a wealth of data due to the increasing level of automation. Remote maintenance is one thing, the recording of Machine data the other. This minimises time and costs in production and at the same time demonstrably raises effectiveness and quality to a higher level.

Our customers need this input in order to implement optimisations based on the data. As our clients work with plastics, the topic of optimisation plays an important role for them. Circular economy a relevant role. The circular economy requires comprehensive networking. We are also challenged when it comes to testing the suitability of pure new plastics on our machines.