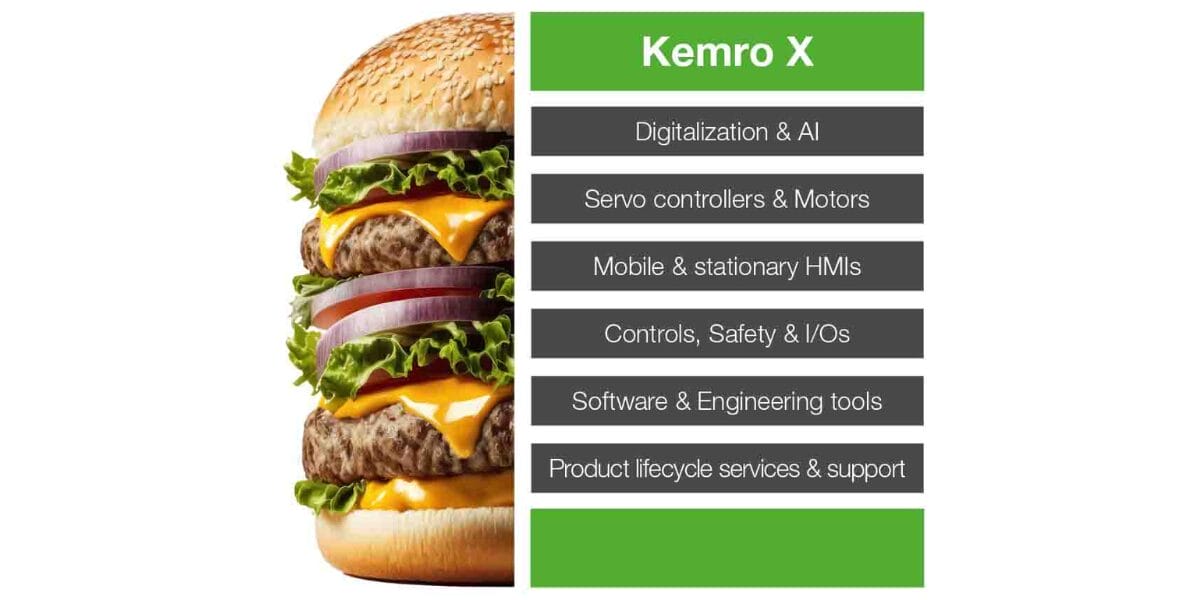

This year, visitors to the Keba stand will be able to create customised automation solutions to suit their taste. This is because the hardware and software components from Keba's Kemro-X product and service portfolio can be combined with each other in a variety of ways to create holistic automation solutions as easily as combining individual ingredients to make a burger.

This motto is also reflected in the Kemro-X live demonstration at the trade fair stand: using the example of an end-of-line solution from packaging technology Products and technologies for systems, robotics and mechanical engineering in a combination of real application and digital twin. In addition to the AI module, the new KeDrive D3-AC all-in-one multi-axis controller and wireless operation with the KeTop Safe Wireless, interested parties can take the Delta robot out of the line, interact with it, have it assemble a burger to their liking and integrate it back into the line.

Shown are a highly dynamic delta robot and the possibilities of the digital twin of a multi-robot system. The simulation demonstrates the operation of four robots on a single control system, making it easy to achieve excellent coordination in the material flow.

The Keba-robotics solution offers machine manufacturers a comprehensive Platform with sophisticated robotics functions as well as the openness for integrating your own technologies. Thanks to the full simulation capability, users can easily develop flexible system concepts as early as the pre-sales process and optimise both the accurately forecast both performance and material flow. In practice, thanks to the Keba robotics solution, the kinematics prove to be more efficient and precise compared to standard solutions, which can lead to an increase in machine performance of up to 15 per cent.

Keba at the SPS: Hall 7, Stand 470