An intelligent splicing system such as the new JetConnect process from Verpackungstechnik Jetter GmbH not only eliminates cost-intensive downtime, but also material waste and material mixing when joining material webs. As a result, users can reliably comply with the strict requirements of the new EU packaging regulation.

Packaging lines in high-volume but price-sensitive applications - be it food, confectionery or household chemicals - are an important factor in the overall operational balance sheet. In this respect, even seemingly inconspicuous elements within the packaging process, such as the web splice, can cost a lot of money and time, for example if manual intervention is required when changing the material web rollers, if the installed process is too expensive or if it requires too much space.

In addition to economic aspects, there is also an ecological and a legal side. Ultimately, both also have economic consequences. The EU Packaging Regulation adopted in mid-February 2025 makes this clear. It requires all companies, including packaging manufacturers and product packaging companies, to adapt their design and material utilisation in such a way that the recycling and reuse rate increases year on year.

In addition to reducing the packaging weight, the key parameters for achieving the target are the use of monomaterials and material purity. Material mixtures that cannot be separated or are difficult to separate may no longer be processed.

PPWR-compliant automatic splicing

What does all this have to do with the automatic roller splice? In fact, much more than you might think at first glance. If the splicing process in the packaging and labelling process is carried out manually or is poorly automated, a lot of packaging material waste can be produced when the old and new rolls of material are spliced together.

And as far as the regulatory requirements of the new EU packaging regulation are concerned, these are also only sub-optimally fulfilled with a sub-optimal splicing system. Over the years, as the requirements of the EU Packaging Regulation continue to become stricter, these deficits mean that the corresponding requirements cannot be met in the long term. As a result, corresponding fines become due or there is even the threat of plant closures.

Exclusively monomaterials

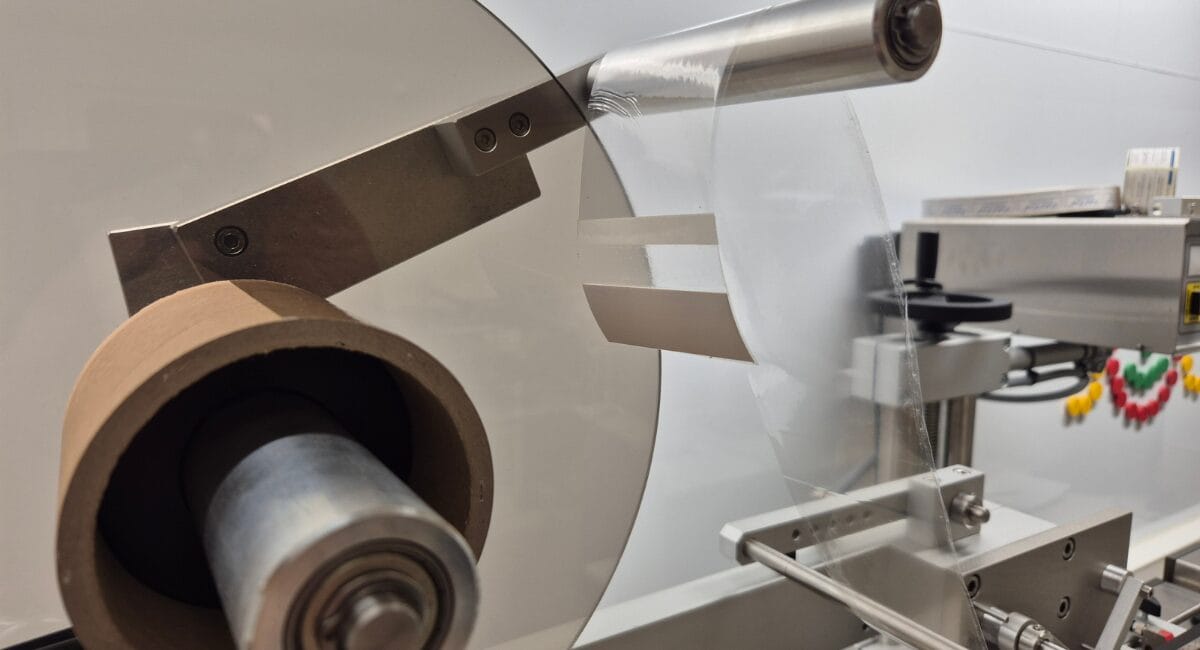

An intelligent splicing system such as the new JetConnect process from Verpackungstechnik Jetter GmbH reliably prevents such a disastrous scenario. At the heart of the splicing process is the JetConnect splicing belt for all types of material web rolls (paper, aluminium, plastic, etc.) or wet glue/hot glue label rolls. The material webs or linerless labels on rolls are joined with a splicing tape identical to the material.

This means that only monomaterials are used for the splicing process. This is achieved through the interaction of splicing tape and a flexible, robust splicing head, which is developed and manufactured by the packaging machine specialist b+b Automations- und Steuerungstechnik in southern Hesse in accordance with Jetter's design specifications.