In May, Theegarten-Pactec will be exhibiting a wide range of machines for primary and secondary packaging at interpack in Düsseldorf. With greater efficiency and the flexible processing of sustainable packaging materials, the machines can save resources, energy and costs.

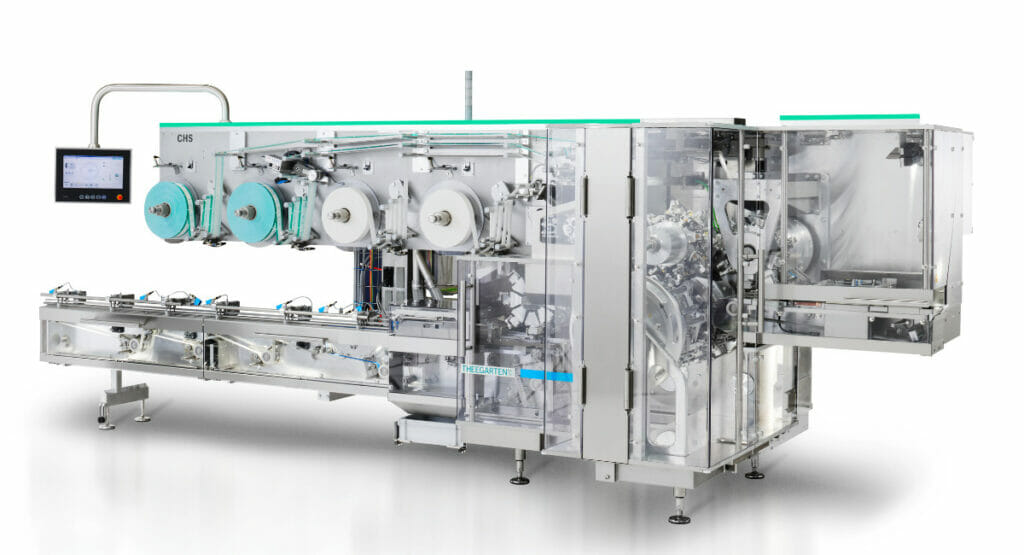

The machines from Theegarten-Pactec combine high performance in the packaging process with flexibility. At the upcoming interpack in Düsseldorf (4 to 10 May 2023), the CHS, which packs chocolate at a speed of 1,800 products per minute and can be quickly and flexibly switched between nine different folding types, will be presented. In addition, the BLM presented a cartoner that is perfectly adapted to primary packaging machines in the high-performance range. and with which the full output of the primary packaging machines can be utilised in the process without any loss of efficiency.

High performance and flexibility are complemented by the sustainability of the solutions: Due to their Modularity and optimum adaptation to recyclable, paper-based packaging materials with consistent high performance customers can produce in a more resource-efficient, energy-saving and cost-effective way.

The company presents its latest flagship: the newly developed CHS. Following successful industrial trials, the machine has been further developed and now processes chocolate products at a speed of 1,800 products per minute. Its maximum flexibility is demonstrated by the quick changeover between nine different folding types. Thanks to integrated assembly devices and reproducible settings for product and material guidance, the required folding types can be retrofitted quickly and easily. In this way sustainably save customers extra floor space for additional machines and energy costs for their operation.

With the FPC5, the company presents a modular high-performance packaging machine that packs chocolate bars and tablets in paper-based tubular bags - using the standard cold-sealing process or the far more complex heat-sealing process. The machine has been further developed so that it can also be used in the High-performance range of 1,500 products per minute delivers the best results. At interpack, an application for larger chocolate bars will be shown, which is produced with a Packed at a speed of 600 products per minute become.

Sustainable packaging

The company shows the CFW-S packaging chocolate bars. The self-developed sealing station is located directly after the actual wrapping or packaging process. As soon as a product - paper or monofilm is used as packaging material - has reached the sealing station, the Sealing tool is brought close to the product, the packaging is sucked onto the sealing stamp with the aid of negative pressure and sealed gently yet firmly within milliseconds. Combined with active cooling, this process does not cause any pressure marks or other damage to the chocolate product.

Thanks to the innovative suction seal technology No need to apply glue dots to permanently seal the packaging. Costs for glue, cleaning and maintenance of the packaging machine as well as set-up and adjustment times can be saved and the packaging process becomes more stable and therefore less susceptible to faults.

Sustainable packaging materials can also be used efficiently and with process stability on other machines. The EK4 at the trade fair stand will be the fastest packaging machine in the world, which packs 2,300 hard sweets per minute with a double twist wrap. Instead of the usual wax paper or film, a paper-based alternative without wax application can also be used and processed stably despite the high speed.

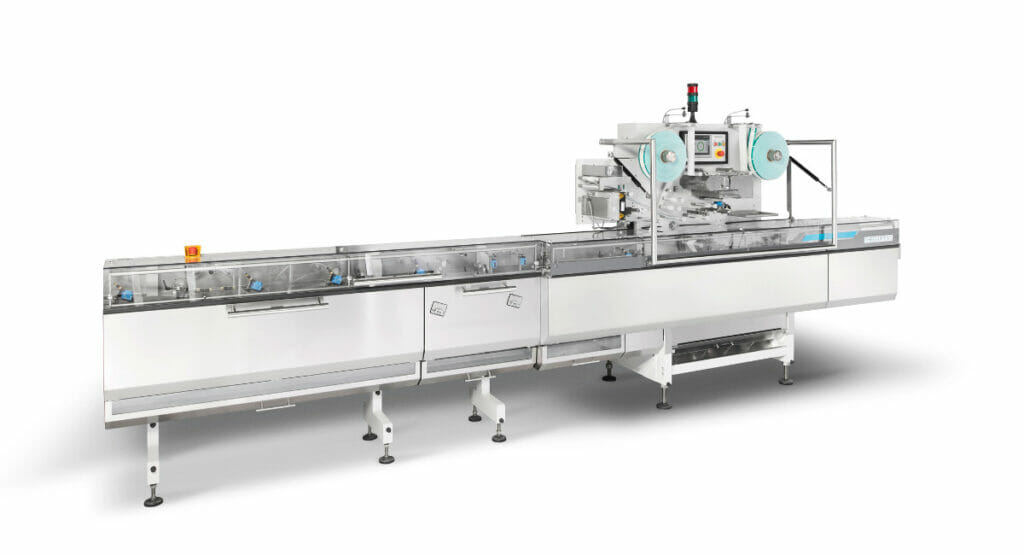

Solutions for secondary packaging

For effective secondary packaging of products, Theegarten-Pactec will be presenting the BLM - the first in-house cartoner directly connected to the FPC5 - at the trade fair stand. The system is Designed for adaptation to a primary packaging machine in the high-performance range. Customers therefore have a powerful machine combination at their fingertips that allows them to utilise the full output for primary and secondary packaging without any loss of efficiency in the overall process.

The company uses the FPH5 to impressively demonstrate how sensitive jelly products for the OTC market can be packaged gently and yet extremely efficiently, thus saving energy and resources.

Visitors to the Bonals stand will be able to see a combination of a stock cube press with the BCW3 from Theegarten-Pactec. The Bonals press is directly connected to the high-performance machine, which packs 1,700 stock cubes per minute. A solution for the medium output range will also be on show: The combination of a tablet press from partner Kilian with the BCW-eco, also via direct connection, demonstrates effective packaging at a speed of 750 soup tablets per minute.

Source: Theegarten-Pactec

Theegarten-Pactec at interpack: Hall 1, Stand B51

More news about packaging machines

Confectionery: Flavour alone is no longer enough

Mettler-Toledo shows inspection solutions in Düsseldorf

interpack 2026 shows trends in the packaging industry

White paper | How to make packaging machines more dynamic through lightweight construction