The base body is reusable, the cover is recyclable: IQPAK is designed to minimise CO2-emissions by at least 70 per cent compared to conventional packaging and combines disposable and reusable packaging. Our guest author Dr Susanne Guth-Orlowski, an expert in the circular economy and digital product passports, took a closer look at the innovative packaging for food in the wholesale, to-go and catering sectors, as well as for chemical and cosmetic products.

IQPAK is an innovative packaging system developed by Löning & Partner in collaboration with the Fraunhofer Institute for Structural Durability and System Reliability LBF and is based on the combination of disposable and reusable components. The system already utilises the digital product passport and thus optimises logistics, consumer experience, recycling and CO2-accounting.

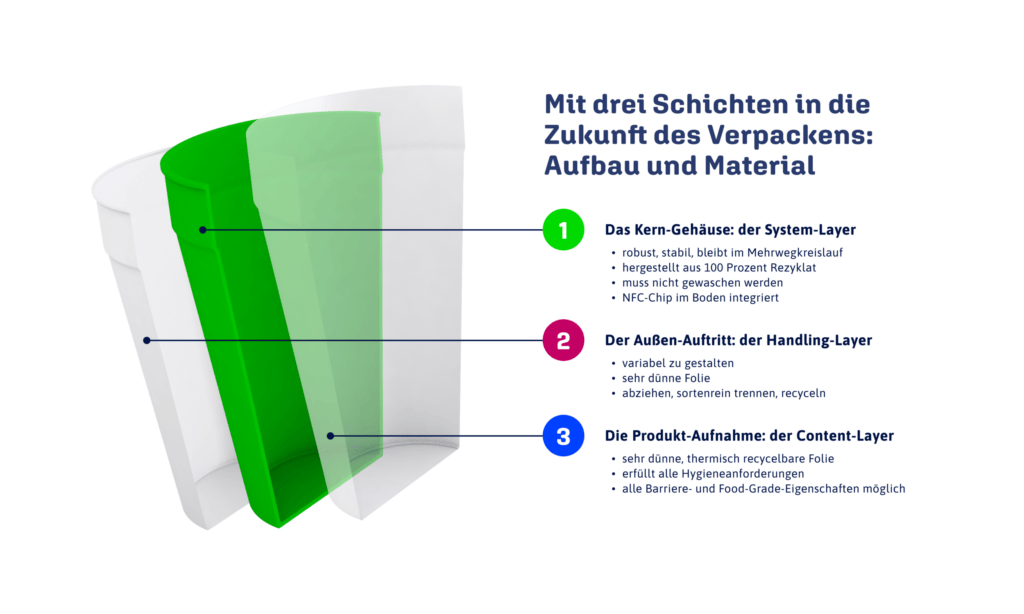

The packaging consists of three layers of material that are not glued together. The outer layer (Handling layer) is used to present marketing and product information. This layer is a one-way element, which is renewed each time it is reused. However, recycled material from the IQPAK cycle is used for refurbishment. The middle layer (System layer) also exists Made from 100 per cent recycled material. It shapes the packaging and makes it robust and stable. An NFC chip is built into the base of this layer, which can withstand up to 300 product life cycles. The chip is powered by a passive coil and does not require a battery. The system layer is the reusable component of the IQPAK system.

The inner layer (Content layer) is Made from new material and is also a disposable component. It fulfils the highest hygiene requirements, especially for food packaging. During refurbishment, a new content layer is automatically placed in the system layer. Around three to four grams of material are required for a 500-millilitre pack, which is fed into the in-house recycling system after each use cycle and reused as a new system layer. All three layers are made of polypropylene monomaterial (PP).

Positive life cycle assessment of IQPAK

The patented packaging requires the following for reuse no energy-intensive washing process. This avoids waste water, chemical detergents and the usual high energy consumption, which has a positive impact on the environment. has a positive effect on the life cycle assessment of IQPAK or the packaged product. An environmental assessment report by the ifeu Institute for Energy and Environmental Research in Heidelberg certifies that the IQPAK system has a cradle-to-grave value of 3.14 kilograms of CO2e. This means a 56 per cent reduction in emissions compared to a commercially available returnable cup that has to be washed.

Intelligent circulation system

The Integrated NFC chip in the base of the dimensionally stable system layer contains all the information on the material properties of all three layers by accessing the data stored in the IQPAK database, which enables the IQPAK multilayer to be separated by type and recycled automatically and easily. This makes it easy to trace each individual packaging, communicate with consumers and implement an intelligent deposit system that makes different deposit value allocations just as conceivable as cross-border recycling.

The „inbuilt“ data of the IQPAK-IT system improves the return of packaging in particular. Each packaging has a unique identity that is linked to the serial number of the chip. The retail partners scan the NFC chip on the packaging and record its location via the Global Location Number (GLN) of the seller or the return station.

This enables an efficient logistics process based on real-time data. The movement of each individual container in the IQPAK cycle, regardless of whether it is in refurbishment, filling, transport, wholesale market, retail, at the consumer, in the return container or at the recycling station, is tracked in real time. written directly to the system database via the scanning process using an NFC chip, This means that the operator always has an overview of the whereabouts of the packaging. This makes it easy to manage the pool of all packaging in circulation and to evaluate the return rate. If the return rate is too low, the deposit on the packaging can even be increased to motivate consumers to return it. The frequency of use of the packaging is thus actively controlled and maximised.

One challenge, however, is that there is often not enough space in stores to take back larger quantities. Johann Löning, Managing Director of IQPAK, sees this as a challenge. In future, intelligent return containers that automatically report when they are full, to be collected when required.

Digital product passport for implementing the R strategies

IQPAK also offers advantages for consumers: By simply reading the NFC chip with their mobile phone, they can find the return points for the packaging. An app is currently being used for this purpose, which also sets the deposit value to zero on return and gives the consumer their money back. As dThe transaction data is only ever associated with the packaging and not with the customer, the solution is completely anonymous and GDPR-compliant.

However, consumers are not only interested in information on returns. Before making a purchase decision, they may want to find out more about the product and its ingredients. The NFC chip allows customers to do this, to receive manufacturer information and also to interact without difficulty. This gives manufacturers direct contact with their target group and allows them to place competitions, campaigns, instructions for use and advertising messages flexibly.

With the NFC chip in the packaging, IQPAK is also ready for the Digital Product Passport today, which will be prescribed by the Ecodesign Regulation for a large number of products from 2027/2028.