One hundred per cent automation of packaging systems sometimes fails due to seemingly minor issues such as the „finite nature“ of label rolls or material webs. Duplex systems are often offered as a solution. However, these are expensive and require a lot of space. In the following, we present a solution that is cost-effective and also works in the smallest of spaces.

Automatic, uninterrupted web splicing of packaging materials is an indispensable element of an efficient packaging line, regardless of the industry. Such packaging materials can be, for example, roll labels - on carrier tape or linerless - or material webs. If the web splice is „stuck“ because, for example, manual intervention is required when changing the label rolls or the installed automatic process is too expensive or requires too much space, then this shortcoming has a significant impact on the overall profitability of the line.

An automatic web splice often pays off even at low speeds

It is now common knowledge in the packaging industry that manual web splicing is not a sensible option at medium and high speeds (from 100 labels per minute), both from a technical and financial perspective. At the same time, manual web splicing is often not economically viable even for packaging systems with rather low speeds (in the case of labelling systems at around 50 to 80 labels per minute).

Rolls of the increasingly popular label brochures (booklet labels), for example, are often only loaded with 300 to 400 labels due to the voluminous label format. Manual splicing therefore results in frequent interruptions to the labelling process and high staffing requirements at the machine. For example, with 400 labels on a roll and a speed of 80 labels per minute, the packaging line would have to be stopped every five minutes with manual splicing.

Splicing process attractive for a wide range of industries

In order to ensure uninterrupted labelling despite reel changes, double label dispensing systems (duplex systems) are currently frequently installed in the corresponding labelling systems.

However, these are expensive per se, require a lot of space and also entail additional costs due to the extra work involved in duplicate coding and control equipment. In industries with high safety requirements, additional costs are also incurred for qualification and validation of the system, both during installation and during operation.

The JetSplice® process from Verpackungstechnik Jetter GmbH shows that the automatic splicing process can also be implemented much more simply and intelligently when changing reels or webs.

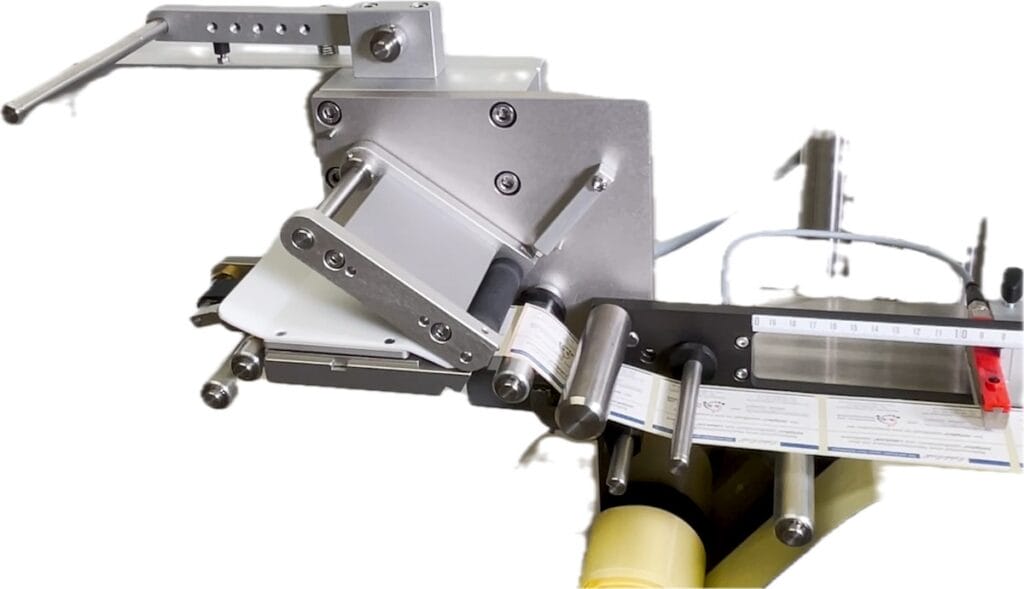

The centrepiece of the splicing process is the new JetSplice® LW (Label Web) splicing tape. The end of a label or material web is bonded to the beginning of a new label or material web roll in a special splicing head using the splicing tape.

JetSplice® LW is an intelligently designed adhesive tape and, thanks to its ingenuity, manages with a splice head that is technically astonishingly simple. This makes the system suitable for a wide range of users and economically attractive for many different industries. The splicing head was developed by the packaging machine specialist b+b Automations- und Steuerungstechnik GmbH according to the design specifications of Verpackungstechnik Jetter GmbH and is also manufactured in their factory.

Technically simple and cost-effective splice head

Label webs from two separate rolls run together in the new splice head. When the upper web reaches the end marked by the JetSplice® LW splicing tape (see Fig. 1), the beginning of the second web provided is automatically spliced on seamlessly, allowing the entire process to continue „endlessly“ without interruption.

The user has time to replace the empty role with a populated new role for the entire duration of the active role.

It is particularly important that no mechanically or optoelectronically controlled movements of splice head components are required to join the label webs.

Thanks to the variably adjustable gap on the splicing head, the booklet labels mentioned above with their different booklet thicknesses can also be processed without any problems.

In addition to the splice head, the Jetsplice® process requires a device to hold two label rolls and optionally two spindles to wind up the empty tape on the labeller. Verpackungstechnik Jetter GmbH supplies a simple solution for this, which can be easily integrated into conventional labelling machines at a later date.

Splicing of material webs or linerless labels on the roll

With the same design JetSplice® splicing head, narrow webs (plastic, aluminium, paper) up to a width of approx. 250 mm or even linerless labels on the roll can also be spliced. Depending on the requirements, a splice can be made with an overlap of the webs or - where no web overlap is desired due to the thickness of the material webs - also butt to butt. In the latter case, the splicing tape is positioned in a Z-shape between the start of the newly supplied web and the end of the processed web. The JetSplice® MW splicing tape (MW stands for Material Web) is used in both cases.

For all splicing processes, the JetSplice® splicing tape is already applied to the roll core by the manufacturer during the winding of the label or material web and attached to it.

Added value for both users and labelling/packaging machine manufacturers

The Packaging Technology Jetter GmbH offers labelling machine or packaging machine manufacturers the components of the splicing process, namely unwinding, splice head, a small tape buffer for very high speeds and, if necessary, an empty tape rewinder as a complete package or as separate units for integration on the respective labelling machine.

The components are available in two standard sizes for belt widths of up to 100 mm and belt widths of up to 250 mm, each with a left or right discharge direction. Other widths are also possible with little additional effort. Details on material transport must be agreed with the labelling machine manufacturer.

The web unwind and the splicing head do not require their own power supply. The drive of the labelling or packaging machine is sufficient here. A take-off motor may only be required for belt speeds of 50 metres per minute or more.

A special publication of the Packaging Technology Jetter GmbH