Adhesive contamination on machines leads to inconvenient cleaning work. Instead of getting annoyed about the symptoms, it is better to tackle the root of the problem. Adhesives expert Jowat has tackled this issue and, often with just a few optimisations, works with its customers to implement cleaner and therefore more resource-efficient and sustainable packaging processes.

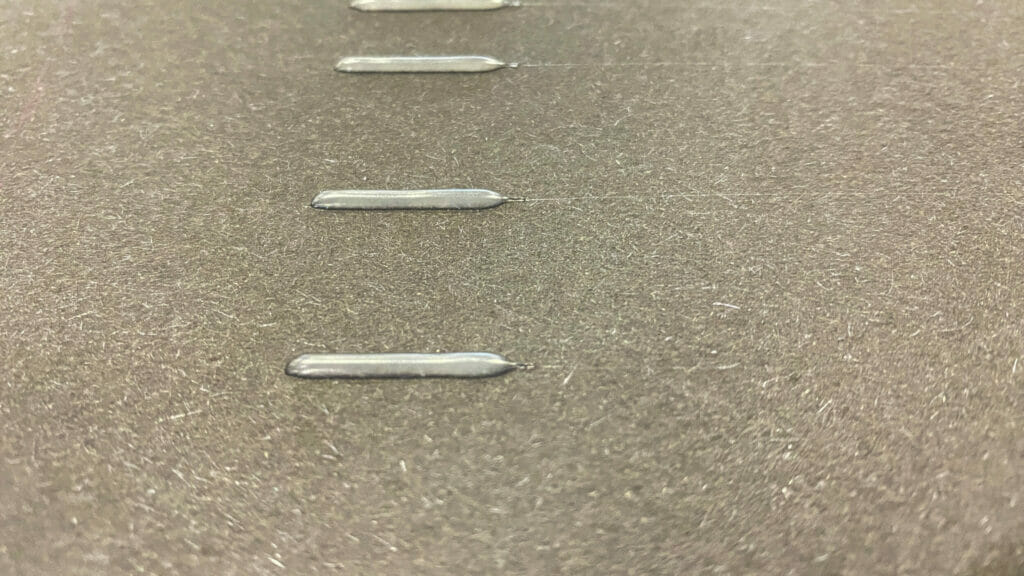

Sealing packaging with hot melt adhesive is a success story: Nothing is as efficient, flexible and reliable in the long term. The hot adhesive is applied to the gluing points in dots or beads using nozzles. The undesirable phenomenon that often occurs here is that the actual adhesive bead drags a hair-thin thread behind it. A common euphemism for this is the term „angel hair“. In specialist circles, this is referred to as thread pulling or thread breakage.

Problem recognised

The length of these thin threads determines the degree of the resulting soiling in continuous industrial operation. If they measure only millimetres on a single caterpillar, they quickly grow to considerable quantities in large numbers. This not only wastes adhesive, but also increases the amount of cleaning required. The result is longer maintenance times and production downtimes.

The triumphant advance of PO hotmelt adhesives is further exacerbating the problem, as this technology is characterised not only by its excellent stability in the melter but also by its broad adhesion spectrum. They adhere well to many surfaces - including machine parts. This makes cleaning and maintenance more difficult. This makes it all the more important that the adhesives only end up where they fulfil their intended purpose. In the worst-case scenario, you end up with dirty and therefore unsaleable goods that have to be laboriously reconditioned or disposed of.

Numerous factors influence thread breakage. If several of them combine unfavourably, the resulting accumulations of threads can form impressive webs. Depending on their size, they are sometimes reminiscent of the realm of the giant spider Aragog from „Harry Potter“. However, such shortcomings can be remedied without the power of magic by identifying and optimising the possible causes point by point - from the process to the application equipment to the adhesive itself.

Optimise processes

You should begin by checking the process parameters, starting with a close look at the processing temperature. This determines the viscosity of the adhesive and has a significant influence on thread breakage. The temperature in the application head is particularly relevant. Just five degrees Celsius more in this area often shortens the threads noticeably. In general, temperature control over the last few millimetres up to application is crucial.

Occasionally, the set values do not exactly match the actual temperatures in the machines. One reason for this could be outdated application devices, for example. The length, position and guidance, including the radii of the heated hoses, can also cause temperature fluctuations depending on the throughput speed and continuity - a possible cause of irregularly forming threads.

However, temperature deviations can also be triggered by environmental factors. Open doors and windows, unfavourably positioned ventilation fans or high process speeds can cause draughts. This can unintentionally cool both the application head and the emerging adhesive, which increases thread formation. In addition, thin threads can be distributed within the machine or in the hall due to draughts.

If the distance between the nozzle and the application surface increases, the resulting filaments also lengthen. The reason for this is the increased temperature difference in the adhesive application: The adhesive is very hot at the nozzle and has already cooled down considerably on the substrate due to the distance. This favours long threads. These distances should therefore be reduced to the minimum possible in the process.

The order position is simple to rectify and yet often neglected. Beads or dots that protrude over the edge of the packaging have no function. They merely increase adhesive consumption and contaminate the machine parts. Short threads within the glued sections are more tolerable than those that are pulled behind them. When applying the adhesive, it is therefore important to ensure sufficient distance from the edge and correct positioning.

However, the optimisation potential for clean thread breakage in the process is limited. Existing system designs set these limits. In principle, a secure closure of the packaging is of course always more important than clean systems. If the results of the measures taken so far are not yet satisfactory, the following adjustments should be made.

The influence of the equipment

In addition to the process conditions, the application equipment also influences thread breakage. Application heads work either electro-pneumatically (air-opening-spring-closing or air-opening-air-closing) or purely electrically without compressed air. All designs allow precise application patterns. In unfavourable process conditions, however, application heads with high clamping force show advantages in terms of thread breakage.

Application nozzles are available in a variety of designs. The capillary volume, i.e. the cavity in the nozzle, is particularly relevant for thread breakage. The smaller this volume in the nozzle tip in front of the valve seat, the more favourable it is for a clean thread break. Needle seat valves therefore regularly perform better in practice than ball seat valves. Experience also shows that problems occur more frequently with multi-channel, slotted or angled nozzles than with short nozzles with only one channel. The nozzle is the proverbial eye of the needle for clean thread breakage.

Adhesive change as an opportunity

If the approaches described so far are not effective or feasible, the only option is to switch to a different adhesive. In general, adhesives with low viscosity favour sharp thread breakage. However, skilful combinations of raw materials can also be used to formulate other adhesives that have little tendency to pull threads.

Cleaner alternatives are usually quickly identified. However, it is then first necessary to check whether the new adhesive can fulfil the prevailing requirements such as short cycle times, high restoring forces, demanding surfaces or special temperature resistance. Jowat carries out these tests free of charge for its customers, drawing on decades of practical experience and a wealth of modern testing equipment. Experienced application experts from the adhesive manufacturer then support the implementation in the production environment. In the best case scenario, the end result is a solution that enables far-reaching improvements even beyond the thread tension.

The goal: more sustainable bonding processes

For Jowat, the optimisation of thread breakage is a pivotal point in the development of sustainable adhesives, as processes subsequently use less material, have less downtime and thus effectively conserve resources. Just how serious this topic is for the Detmold-based adhesives manufacturer is demonstrated not only by a number of collaborations with the scientific community - Munich University of Applied Sciences - and leading mechanical engineering companies, but also our own research efforts. Just last year, Jowat invested in a state-of-the-art system for the meticulous analysis of thread breakage behaviour. This system simulates a wide range of different process conditions. Whether temperature, pressure, distance, speed or different application heads and nozzles: everything can be flexibly adjusted and set with repeat accuracy. This is important because every adhesive reacts differently to the various combinations of these factors.

With regard to the problem of thread pulling, it must be said at the end: There are a few rules of thumb and general tips, but there is no panacea. Nevertheless, his extensive knowledge of application technology inspires the adhesive manufacturer to develop new and ever more optimised high-performance adhesives. With the aim of always being one step ahead of the market in terms of sustainability.

Further news from the field of green packaging

Delfort switches paper production to fossil-free energy

Italy impresses in Nuremberg

Fraunhofer software optimises shipping cartons

Sustainability as a driver of innovation in cosmetics packaging