The Austrian dairy NÖM AG (Niederösterreichische Milch AG) is modern, innovative and a pioneer in Europe. The range now includes around 800 dairy products. It includes evergreens such as „fru fru“ fruit yoghurt as well as newcomers such as the „nöm PRO“ product line. In order to produce this variety of products, around one million litres of milk are processed and bottled every day at the production site in Baden. And before delivery, it is briefly stored on 8,000 pallet bays.

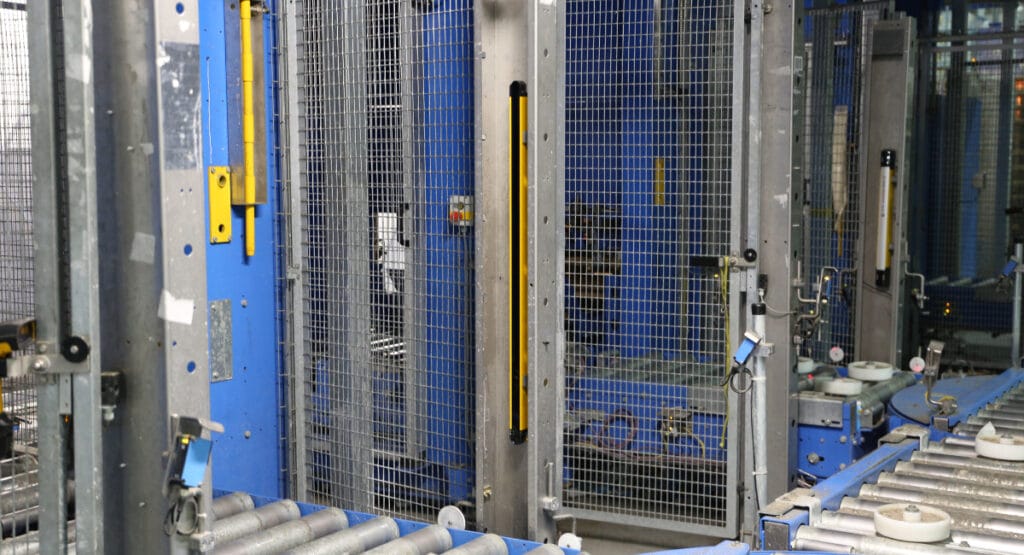

In the meantime, the configurable small controller PNOZmulti 2 from Mushroom the main responsibility for a Deliberate short-term bridging of the safety function installed there - i.e. for efficient muting.

The history of NÖM dates back to 1898, when Frank von Pirko founded Niederösterreichische Molkerei reg. Genossenschaft mbH. Since then, the company has developed into a internationally successful trendsetter, which, with a current export quota of around 45 per cent, no longer only supplies the Austrian market with product innovations. The fact that the milk processing company, which has been based in Baden near Vienna since 1975, consistently produces strong brands has long been proven by NÖM with the „fru fru“: Austria's oldest fruit yoghurt brand has been around since the 1930s - and it continues to enjoy great popularity. „We were the first to present a special low-fat range - our ‚fasting line‘. We were pioneers when it came to GMO-free products and, more recently, we have been at the cutting edge with nöm PRO, a product line with a high protein content,“ says Christina Keil, Corporate Communication at NÖM AG, listing a few examples of the innovative power that has always driven the Lower Austrian company.

From raw milk to dairy product without downtime

NÖM's fresh milk warehouse is staffed 24/7. It works around the clock to ensure that the products made from the delivered raw milk are ready for delivery as quickly as possible. „Calculated over the course of a year around 420 million kilograms of raw milk, which we process into yoghurt, curd cheese, butter, cocoa, kefir, protein drinks and much more“, says Christina Keil, emphasising the diversity of the Lower Austrian dairy's product range on the one hand and the quantities of milk it has to deal with on the other. The raw milk is delivered daily, at least one million litres per day from a total of 2,500 family farms in Lower Austria, Burgenland and Eastern Styria. This means that longer plant downtimes are a no-go in Baden, especially as this is NÖM's only production site. This made it all the more bitter for Michael Hronek, automation engineer and head of control technology, when the previously used muting relay, which fulfilled its task over a large area with a total of around 30 palletiser entries/exits, was discontinued without an adequate successor model being offered.

Strong replacement for muting controller found

„The problem was that the existing application was not so easy to replicate, because in our case the higher-level control system is integrated into the muting. And this should not be affected by the necessary conversions.“

Michael Hronek

It was therefore necessary to Imitate the functionality of the existing evaluation relay and its interaction with the light grids from the same manufacturer on a one-to-one basis. A challenge that the system integration experts from Pilz mastered with flying colours, as Michael Hronek praises: „Everything really worked out perfectly, from the planning to the installation of the new components and the safety-related acceptance. And our ‚saviours in need‘ were also extremely flexible in terms of time.“

The configurable small controller PNOZmulti 2 from Pilz has taken over the infeed and outfeed of the goods. It ensures that a the installed safety function is bypassed at short notice as intended - in other words, that the muting functions smoothly. All changes that affected the small controller PNOZmulti were clocked in during the CIP (Cleaning in Place) cleaning that takes place every few days. To to avoid additional downtime, Pilz completed the installation of the automation system PSS 4000 for multiple stations in one weekend. „Even the sales department got involved to ensure that everything went as quickly as possible,“ says the Head of Control Technology at NÖM AG, alluding to the fact that even his main contact person Markus Stockhammer, Solution Sales Manager at Pilz Austria, lent a helping hand during the hot conversion phases.

Focus on hygiene and tamper protection

One-to-one replication of existing functionality

Two of NÖM's three large palletising systems were converted. The aim was to optimise both the replace the previously used relays as well as the light grids. This is because a combination of both was absolutely necessary for the previous optoelectronic protection system to be used as intended. „When we received a solution was presented, which harmonises with a wide variety of safety devices as long as they can be operated with two channels, Pilz opened the door for us. After all, especially in times like these, when there are supply bottlenecks for many products, it is important to be as flexible as possible,“ says the Head of Control Technology.

Pilz took over the engineering for NÖM and programmed a one-to-one replacement, which ultimately fulfilled everything on the list of requirements: Reliability, a high level of safety based on state-of-the-art technology, easy adaptability to new conditions - and therefore future-proof - and finally a solution from which the higher-level system control remained independent.

Comprehensive solutions for packaging

Successful takeover

All this was only possible after intensive study of the manual for the monitoring unit with integrated muting controller to be replaced, especially since not only a communication or switching sequence had to be modelled, but a specified time cycle also had to be adhered to.

„When the plant control system announces a pallet, PNOZmulti or PSS 4000 now takes over the role of the previous muting relay, removes two control outputs, has this action confirmed by our higher-level standard CPU and only then releases the override for goods transport. In the meantime, the functionality of the connected light barriers is also monitored cyclically and the positioning of the pallet is checked.“

Michael Hronek

„If of the few remaining ‚old devices‘, we now have a replacement that works via plug & play. That's our favourite way of doing things,“ concludes the Head of Control Technology with a smile. Further projects with Pilz are already being realised.

Pilz solutions were also used by the customer SEMA for the Cardboard box feeder used.

More news from the magazine

Traffic lights prevent bottlenecks

Three applications, one solution

Translucent paper seal labels for pharmaceutical packaging

Packaging machine manufacturer in flow