Artificial intelligence and digitalisation play a key role in reducing the ecological footprint of the entire plastics industry and can contribute to the sustainable transformation of the plastics value chain.

On the occasion of Fakuma, the international trade fair for plastics processing, which opened yesterday, Ingemar Bühler, Managing Director of Plastics Europe, explained how artificial intelligence and digitalisation can be used to sustainable transformation of the plastics value chain and can change the working methods, performance and sustainability of an entire industry.

Through intelligent product design, products ranging from packaging and electronic devices to buildings can be designed in such a way that they require less material and at the same time fulfil customer expectations. AI algorithms also accelerate the development of more environmentally friendly materials with improved properties such as durability and environmental compatibility. Precise machine control and communication can also optimise production processes, thereby reducing energy consumption during plastics processing. Fakuma, with its almost 1,500 international exhibitors, will be showcasing a wide range of practical examples of this development until 21 October.

Digital product passports facilitate recycling

In future, digital material and product passports will be able to provide reliable Information on material properties, processing, reparability, remanufacturing and recycling and enable manufacturers, users and disposal companies to exchange standardised data throughout the entire product life cycle.

Thanks to artificial intelligence and digitalisation, the recycling process is also becoming more efficient. Modern sorting systems, for example, use digital labelling and AI algorithms to automatically classify plastic waste. In addition, AI-controlled robots and the automation of disassembly support the recovery of valuable plastic components from complex applications such as mobile phones and tablets. The fully automated recycling robots from Apple Inc. are the best example of this. The combination of AI and automation therefore helps to recover valuable plastic components and raw materials from end-of-life products and to recycle more.

„The ongoing digitalisation of the plastics industry is opening up a new chapter of innovation and sustainability. Companies that make the most of these technologies will be able to reduce their environmental footprint while bringing competitive products to market. Overall, AI and digitalisation are making a significant contribution to making the entire circular process more efficient, designing better products and reducing the use of materials and waste. Our aim is to maintain and even improve performance while significantly reducing the impact of the plastics industry on the environment.“

Ingemar Bühler, Managing Director Plastics Europe

Source: Plastics Europe

Fakuma - More news

Fakuma starts in Friedrichshafen

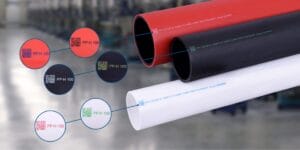

Plastics colour-coded

Sustainable colour and masterbatch solutions

Digital solutions at the Fakuma

Focus on sustainable packaging and plastics