The packaging industry is undergoing radical change and requires sensor solutions that are tailored to complex, frequently changing tasks and fulfil the increasingly demanding standards of quality, safety, brand protection and documentation.

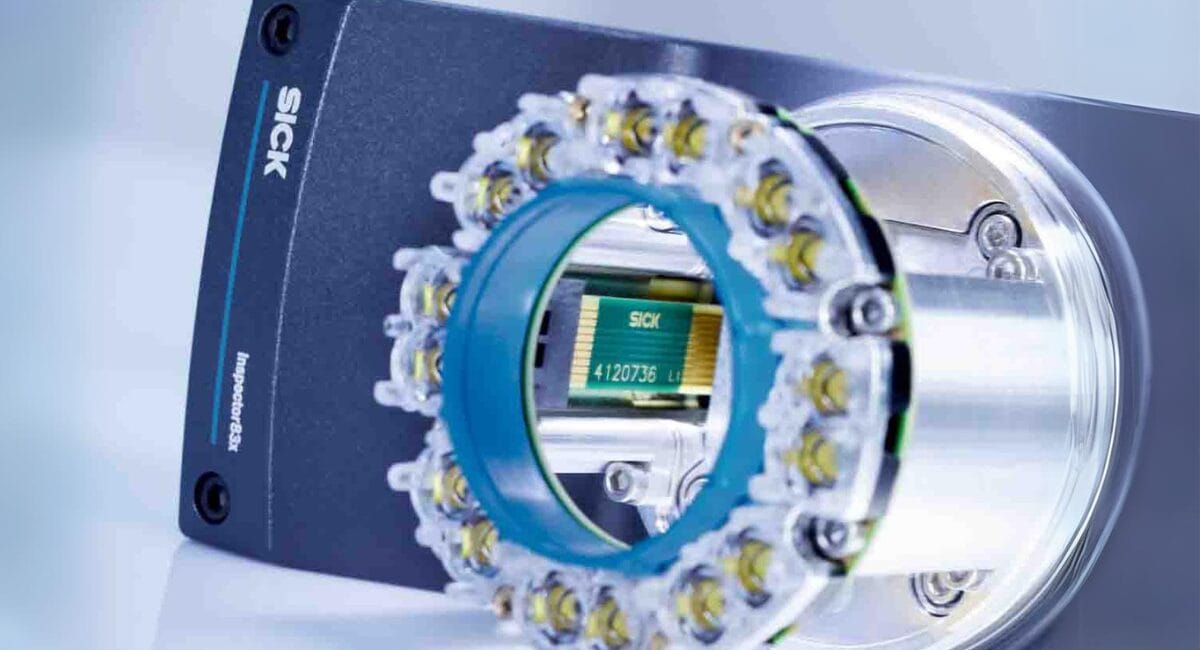

Sick will be presenting innovative sensor solutions for process and quality control as well as machine safety. Exhibits such as the Inspector83x 2D vision sensor for inline inspection or the Missing Item Detection Sensor (MIDS) for automated completeness checks offer powerful AI functions that require no expert knowledge to set up and use via an intuitive, browser-based user interface.

The trade fair presentation will also focus on the topic of machine safety. The new Safe Adaptive Access protective device with dynamic protective field adaptation for infeed and outfeed sections of packaging systems. The company also has the Complete solution Incoming-Goods-Suite for automated goods receiving and the W10 diffuse sensor series, whose strengths include the reliable detection of packaging with different or challenging surface properties such as gloss, colour or textures.

With the Inspector83x 2D vision sensor for inline inspection tasks in high-speed production lines and the MIDS for automatic completeness checks in packaging processes, the specialists are presenting two sensor solutions with integrated AI functionality. With a resolution of up to five megapixels and integrated lighting, the new Inspector83x is a practical all-in-one product. Sick Nova provides the software basis for its configurable image processing solutions.

The MIDS is able to effectively monitor packaging processes and reliably detect missing objects in secondary or tertiary packaging, pharmaceutical packaging or even reusable containers using 3D sensors, among other things.

Sick at the FachPack: Hall 7A, Stand 645