At LogiMAT 2024, Knüppel Verpackung will be presenting its latest product developments and solutions for efficient intralogistics, including a new high-performance machine stretch film. Also on show will be an ergonomic hand stretch system, a material-saving system for cavity filling as well as a pack density-optimised solution from our own packaging development department.

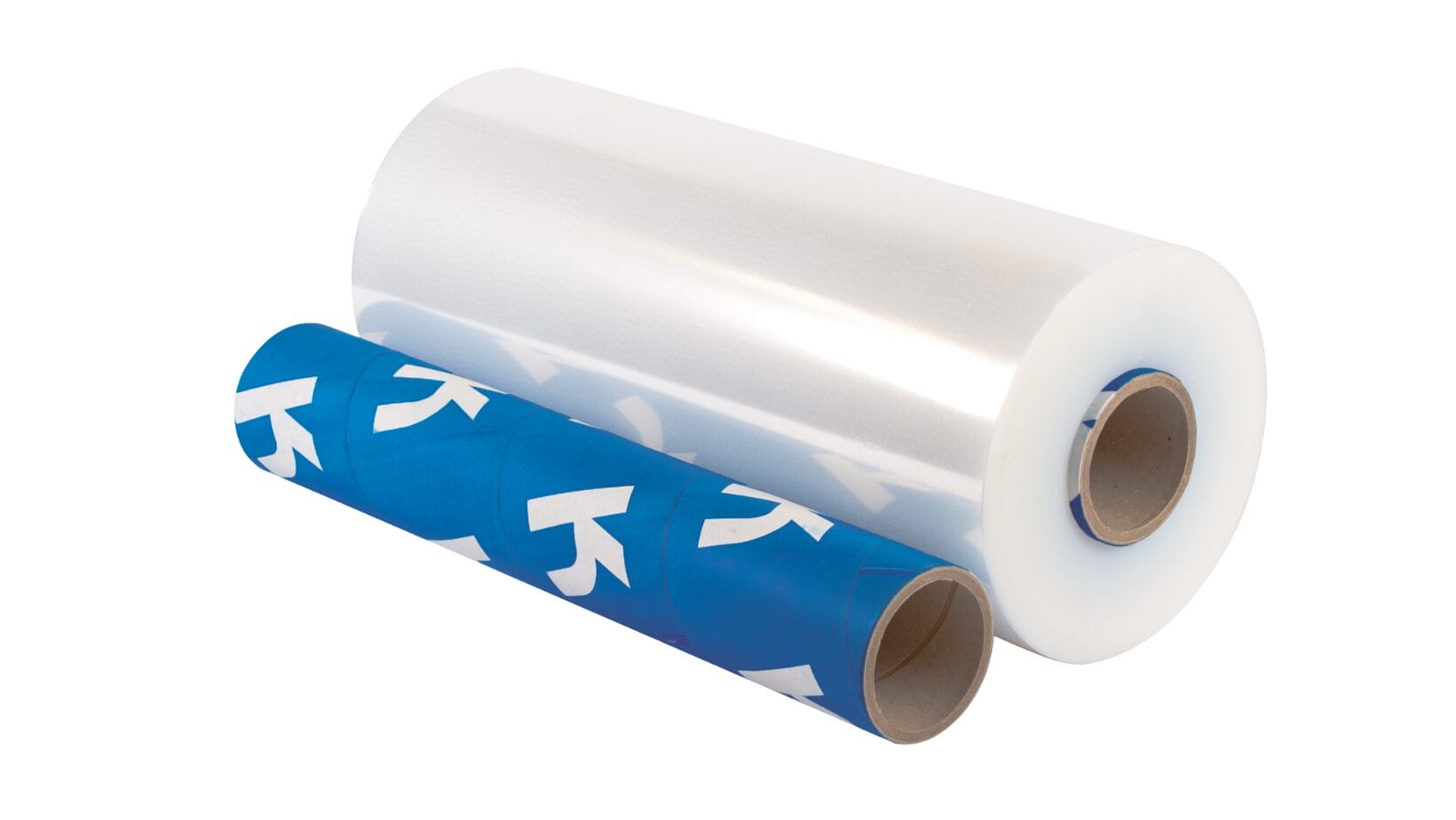

„Reducing material consumption and waste are currently important concerns in intralogistics. We are addressing both of these with our packaging solutions, without losing sight of the issues of process reliability and ergonomics,“ explains Marco Growe, Sales Manager at Knüppel Verpackung. For example, with the new high-performance machine stretch film, which the southern Lower Saxony-based company will be launched this spring under the name KV BlueCast. The 67-layer nano film has a high puncture resistance and therefore ensures process reliability. Thanks to its good stretchability and reduced thickness, it is also economical to use. The new stretch film from Knüppel covers a wide range of applications. Visitors to the stand will be able to see for themselves how the film can be processed without tearing; it will be presented on a stretch wrapper with a dual-motor pre-stretch system.

If you transport your packaged goods on pallets, it is important to secure them properly so that the goods are not damaged. Traditionally, pallets are wrapped with stretch film to create a load bond between the packaged goods on the pallet. In combination with an effective anti-slip paper, however, film consumption can be significantly reduced. The anti-slip paper presented at the Knüppel stand holds the packaged goods securely in position even at an angle of 50°. As an alternative to corrugated cardboard layer pads, the anti-slip paper saves material and storage space thanks to its smaller volume.

Material-saving cavity filling

The new FillPak Trident Mini paper converter with its triangle-shaped paper pads offers material-saving and very fast filling of cavities, as the triangular shape has a significantly higher volume yield than previous paper solutions. With the Trident Mini paper consumption can be reduced by 20 to 25 per cent. Depending on the paper quality used, the pads are also suitable as cushioning transport protection.

The AvvolTec Buzz n‘ Pack horizontal wrapper, which was also presented at Logimat, significantly simplifies and speeds up packaging processes. The semi-automatic system Fixes packaged goods quickly and securely with film at the touch of a button („buzzer“) on a corrugated cardboard tray. The fully wrapped tray with the packaged goods can be placed directly into the prepared shipping carton. As the machine does not require a conveyor line, packaging can be decentralised and carried out directly at the packing table. The system, which is suitable for e-commerce, logistics and fulfilment, also has ecological benefits: the end customer has less waste as no additional void fill is required and recycled film can be used.

Precise corrosion protection

Knüppel also offers effective corrosion protection during transport and storage with the Valeno Layertray - an important topic in intralogistics. Load carriers with pre-formed receptacles such as toothed strips and trays made of corrugated cardboard, fibre cast or plastic are Laminated with an anti-corrosion film for accurate contours. The lamination removes the corrugated cardboard and the fibre casting's corrosive properties in contact with metals and reliably protects the metal parts from corrosion. The layertray is a sustainable corrosion protection solution because paper fibre products are used and the film is so thin that the tray can be disposed of in waste paper after use.

Source: Billet

Knüppel at LogiMAT 2024: Hall 4, Stand 4D34