KraussMaffei will be presenting two new injection moulding machine series at K 2022: the precisionMoulding and powerMoulding machines ensure efficiency and cost-effectiveness. Standard applications for packaging and medical technology will also be on show.

The precisionMoulding is the basic machine with a reduced range of options from the all-electric PX series, while the powerMoulding is the counterpart to the proven hydraulic GX series from KraussMaffei.

„With the basic machine concept, we offer our customers particularly fast response and therefore short delivery times, enabling them to operate even more efficiently and competitively. This opens up completely new market potential and applications for our customers. At the same time, of course, it also opens up completely new applications and customer groups for us that we were previously unable to serve.“

Xiaojun Cui, Executive Vice-President New Machines Business at KraussMaffei

Depending on the application, powerMoulding allows up to 15 per cent more throughput than comparable standard injection moulding machines on the market. This is ensured by the short dry cycle times, the high shot weight consistency and the associated low reject rates. In the wake of rising energy prices, energy-efficient production is becoming increasingly important. The precisionMoulding good energy efficiency thanks to the all-electric machine concept itself. The powerMoulding offers the proven BluePower servo drive as standard. This controls the pumps according to the optimum demand/energy requirement. This means that only consumes as much energy as is currently needed. Overall, depending on the application, powerMoulding offers up to 40 per cent better energy efficiency than comparable standard injection moulding machines on the market.

The powerMoulding 1300-11900 with a clamping force of 13,000 kN is part of the complete circular economy at the trade fair stand. It produces door modules for the automotive industry from 100 per cent recycled PP. The Recyclate in turn comes from caps for insulin pens produced on a PX 200-1400. The material is shredded and then processed with additives such as adhesion promoters and liquid colour in an upcycling process on a ZE 28 BluePower twin-screw extruder.

The APCplus machine function also plays an important role in this application on the powerMoulding. It reliably compensates for the usual batch fluctuations when processing recycled material and thus ensures consistently high component quality here too. An integrated linear robot from the LRX series handles the components safely.

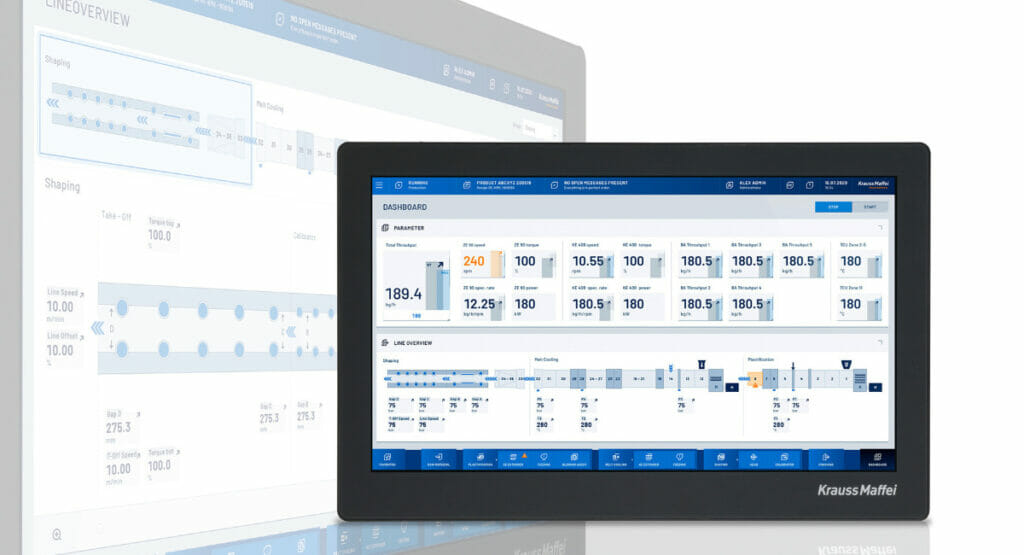

Premiere of user interface for extrusion systems

KraussMaffei will also be presenting a premiere at the trade fair. The company is presenting processControll, a new user interface for its extrusion lines. The core features of the new interface are so-called Wizards that provide the operator with step-by-step instructions for specific work steps., such as starting up or shutting down the entire system.

„With the new user interface of our process control system, we have mastered the challenge of creating a clear, intuitive unit that ideally reflects the complexity of every plastics and rubber processing operation. Now the operator receives the right information at exactly the right time and can also store their experience in the system so that other operators can also benefit from it.“

René Jordan, Teamlead Control Technology Automation Extrusion

This means that even a less experienced employees the control over a complex extrusion process. Operating errors are reduced, resulting in less downtime and therefore greater production efficiency. Deviations from target values are indicated at an early stage by corresponding visual feedback, so that intervention is possible before it is necessary.

Source: KraussMaffei

KraussMaffei at the K 2022: Hall 15, Stand C15/C24-D24

More news on plastics and composites

Returnable solution for e-commerce returns

interpack 2026 puts packaging materials in the spotlight

Refresco uses laser technology for lighter PET bottles

Starbucks strengthens cup recycling