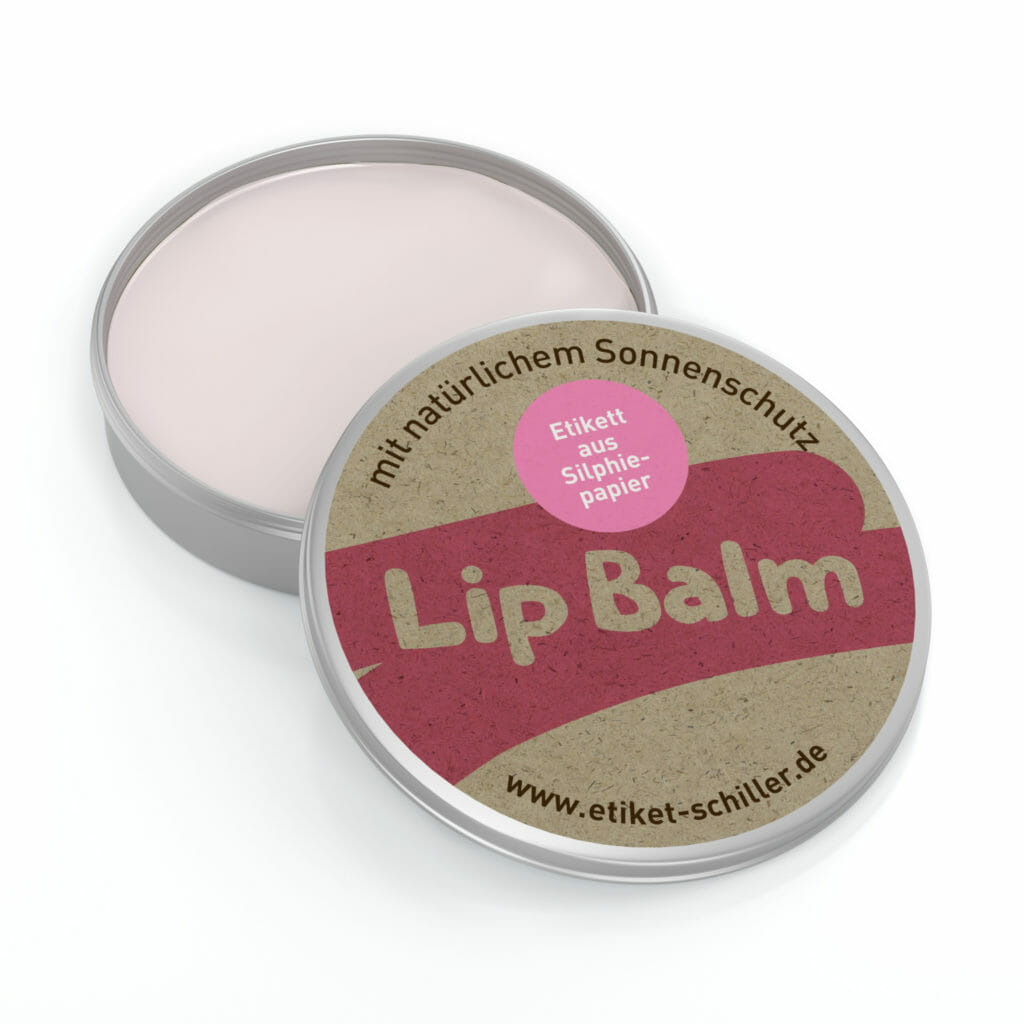

The printing company Etiket Schiller is launching an innovation on the market with labels made from silphia paper. They consist of 35 per cent silphia plant fibres, and in future this figure is set to rise to 50 per cent.

With the material manufactured in Germany, the Label Schiller its environmentally friendly portfolio and offers customers a further option for a Green Packaging in the cosmetics, beverage and food industries.

The Silphie plant, which originates from North America, has already been cultivated in Germany for several years for bioenergy production. The fibres can now be separated and ideally used in combination with conventional wood pulp for paper production. The remaining plant components are still used in the form of a fermentation substrate in the biogas plant to generate energy. The production of Silphie paper therefore enables additional added value. Regional cultivation means less CO2 are emitted than when importing wood pulp, for example from South America.

Dispose of silphie paper labels via the waste paper cycle

For paper production, the silphie fibres are prepared using a biothermal process. The individual fibres are then mixed with wood pulp. Dewatering the mixture produces a uniformly woven fleece. The paper currently consists of at least 35 per cent Silphie fibres, and in future this figure is set to rise to 50 per cent. Like conventional paper, labels made from Silphie paper can also be recycled in the regular waste paper cycle.

Sustainability made in Germany

Label Schiller is one of the first companies in Germany to offer its customers labels made from this sustainable paper. Individual fibres from the Silphie plant are recognisable in the structure of the material - this gives the labels a natural look and special feel. The labels can be printed untreated or embossed to give them an elegant yet natural appearance. Silphie labels can be used in dry and non-humid environments.

„We are delighted to be the first print shop to offer labels made from Silphie paper - a highly sustainable product ‚Made in Germany‘. The Silphie fibres are produced near Lake Constance and are used on behalf of the OutNature GmbH processed into Silphie paper. The Herma GmbH produces the adhesive material for further label production. Etiket Schiller advises interested customers on the new paper and takes care of printing and finishing the labels. This local proximity of all partners involved shortens transport routes and thus reduces CO2-emissions further.“ Susanne Daiber, Managing Director at Etiket Schiller

Many advantages for the environment

Another advantage of using Silphie fibres: the plant, also known as Danube Silphie, is a perennial crop. This means that the plant overwinters after the autumn harvest and sprouts again the following year. The lifespan of the Silphie plant is around 15 to 20 years.

And nature also benefits from the cultivation of Danube silphia in several ways: in contrast to energy maize, the cultivation of the silphia plant requires few to no pesticides and protects against erosion by constantly covering the soil. The plant also independently builds up humus in the soil of the cultivation area and binds carbon. Thanks to a long flowering period, the Silphie plant also provides an ideal habitat for bees, wild animals and other insects.

Source: Label Schiller