Leonhard Kurz will be presenting innovative technologies for label finishing at Labelexpo Europe 2025 from 16 to 19 September in Barcelona under the motto „re:think what's possible“. The focus will be on digital design processes, live machine demonstrations and sustainable transfer solutions.

With a holistic approach to label finishing, Leonhard Kurz will be exhibiting at the Labelexpo Europe 2025 on. The company presents itself as a partner along the entire process chain - from design and pre-press to the final presentation at the point of sale. The centrepiece of the trade fair presentation is the DREAMCOMPOSER, a software for real-time visualisation of labels that generates fully finished 3D prototypes from simple PDF files. These can be realistically displayed on packaging and immediately customised.

Live demos and innovative transfer products

Kurz will also be offering machine demonstrations on the DM-UNILINER 3D and a new system from its subsidiary Mprint. Embossing stamps from Hinderer + Mühlich (H+M) will also be on show. Visitors will be able to experience the entire label finishing value chain in live operation.

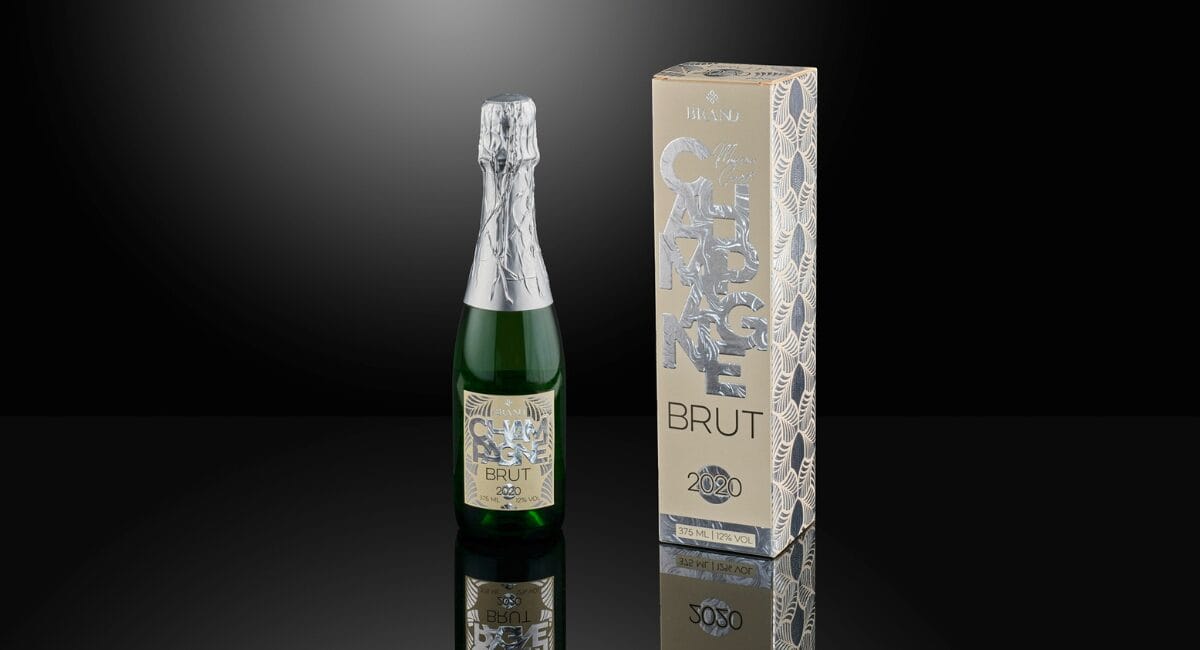

The focus is on the SILVER LINE and LUMAFIN transfer lines, which are particularly suitable for premium labels in industries such as cosmetics and beverages thanks to their metallic or translucent effects. The designs realised on thin carrier material not only provide visual highlights, but also enable resource-saving production.

Sustainability through slim technology and recycling system

With the further development of its slim technology, Kurz says it is significantly reducing the amount of material used while increasing efficiency. Products such as KPW XU slim and ECOFIN CWO slim stand for more running metres per roll, less waste and a lower carbon footprint. No plastic film remains on the end product during the finishing process, as the PET carrier is completely removed.

Kurz is also demonstrating a further step towards a circular economy with the RECOSYS 2.0 take-back system. The aim is to consistently recycle surplus carrier materials from hot stamping products. H+M's sustainable approach is further supported by the use of recyclable brass embossing dies.

Source: Leonhard Kurz