Environmentally friendly packaging is becoming increasingly popular in light of the new German Packaging Act, the debate on marine litter, microplastics and the circular economy. But how can ecological benefits be determined?

On behalf of Poly-clip System GmbH & Co KG, Fraunhofer UMSICHT has ecologically evaluated various types of packaging for sausages. The results show that the choice of packaging saves CO2 emissions.

Life cycle assessments are used to determine the carbon footprint of a product throughout its life cycle and provide information about its impact on the climate. In order to determine how environmentally friendly its packaging solutions are, Poly-clip System GmbH & Co. KG commissioned Fraunhofer UMSICHT to investigate different types of packaging for meat products and to compare clip closure solutions with tray and thermoformed packaging as well as injection-moulded cups for defined meat products.

Life cycle assessment of packaging

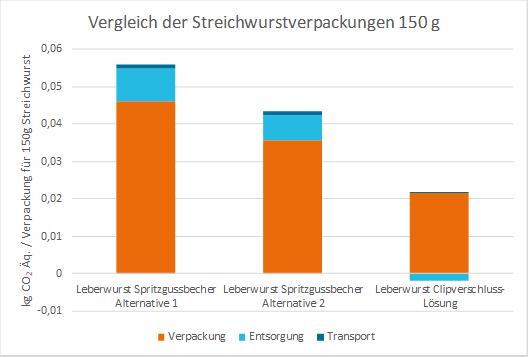

In order to determine the carbon footprint, the extraction of raw materials (e.g. crude oil) through to the finished packaging solution was taken into account in the ecological analysis, including the disposal of the packaging. The packaging solutions were compared on the basis of a reference unit. For this purpose, the packaging of 150 g of spreadable sausage was assumed for spreadable sausage packaging and the packaging of 150 g of cold cuts for cold cuts packaging.

The calculation is initially based on the weight, materials and manufacturing processes of the packaging solutions. The materials were analysed using infrared spectroscopy and the manufacturing processes of the packaging plastics were mapped using commercial life cycle assessment databases.

Results

„When using the clip closure solution for cold cuts, around 0.05 kg of CO2-equivalents can be saved. Extrapolated to the consumption of cold cuts in Germany, this results in a saving of 4,090 tonnes of CO2-equivalents per year and corresponds to around 30,000 kilometres driven by car. In the case of spreadable sausage packaging, using the clip closure solution saves up to 0.04 kg of CO2-equivalents per reference unit and 3 270 tonnes of CO2-equivalents in relation to total German consumption of spreadable sausage per year“.

Nils Thonemann, Sustainability and Resource Management at Fraunhofer UMSICHT

Source: Fraunhofer UMSICHT