By making two targeted changes to its packaging trays, Bauck Mühle has achieved significant savings in CO2-emissions were achieved. Together with partner Smurfit Westrock, the design and the type of corrugated cardboard were adapted, resulting in an annual saving of almost 30 tonnes of CO2 leads.

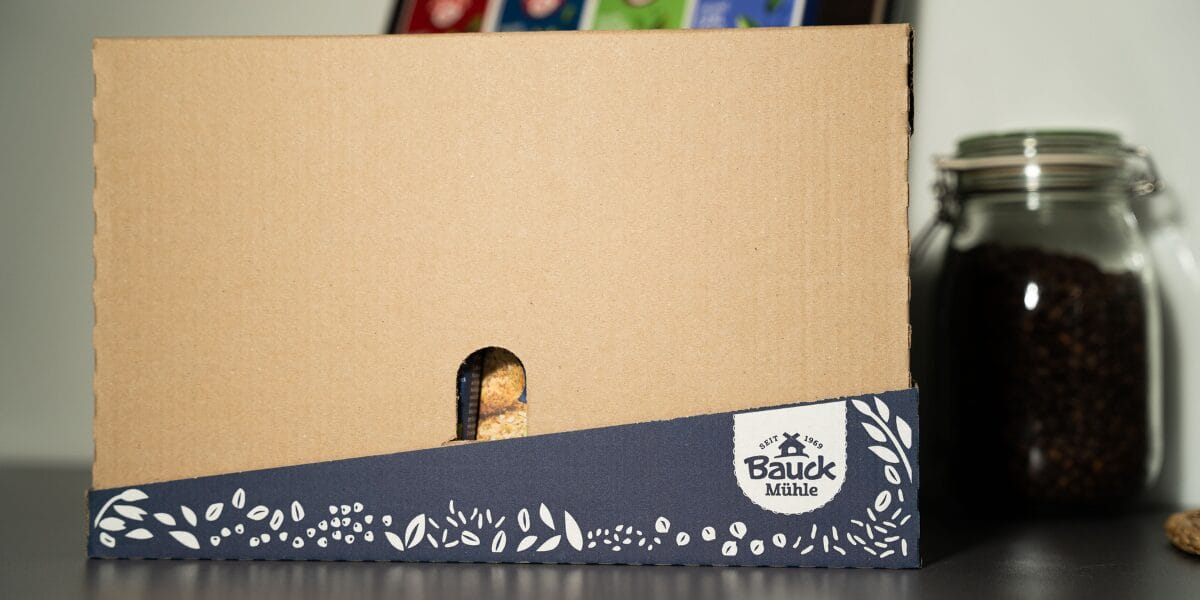

The organic food company Bauck Mühle, in collaboration with the packaging company Smurfit Westrock one Sustainable optimisation of your packaging trays made. A sustainability scan by Smurfit Westrock resulted in two changes: The Inclined packaging trays was adjusted and the Shaft type of the lids was changed. These measures have a significant impact on the company's environmental friendliness and logistics.

The modified slope of the packaging tray made it possible to Excess material reduced by 30 per cent This corresponds to a saving of around 130,000 square metres of packaging waste per year. In addition, the change in flute type from B-flute to S-flute for the lids meant that 14 per cent more goods fit on one pallet, which saves 32 lorry loads per year.

The improvements not only ensure more efficient logistics, but also a reduction of almost 30 tonnes of CO2 per year.

„The collaboration with Smurfit Westrock shows how we can improve our sustainability performance with just small changes.“

Katrin Posch, Sustainability Manager at Bauck Mühle

Source: Smurfit Westrock