As an expert in conveyor and storage technology, Leuze electronic will be showcasing efficient sensor solutions for optimising intralogistics and material flow processes at LogiMAT 2020.

The Intralogistics expert shares the vision of intelligent production (Smart Factory)in which production facilities and logistics systems will be without human intervention organise it yourself. Continuous conveyor and Driverless transport systems (AGVs) carry out logistics orders independently and navigate automatically. Effective and safe sensor solutions will take centre stage at the LogiMAT trade fair in 2020.

"The aim is to use our efficient sensor solutions to make our customers' material flow and automation processes even faster and more economical," explains Matthias GöhnerCorporate Industry Manager at Leuze electronic.

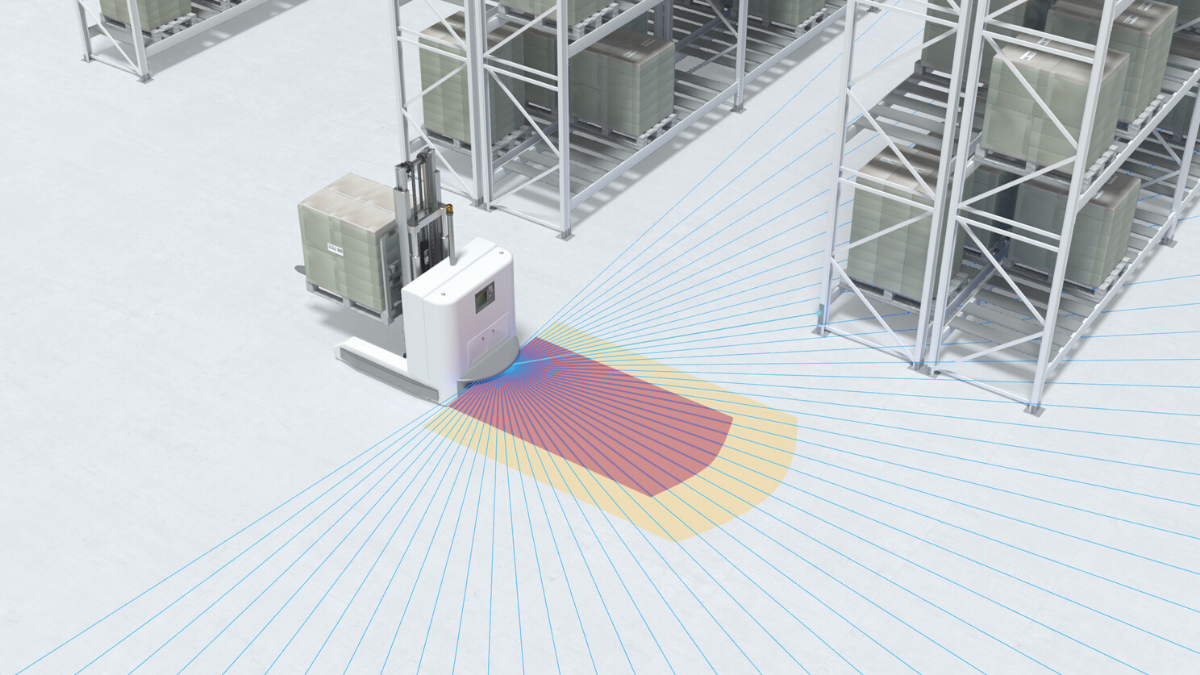

Leuze supports vehicles that Navigate on the basis of natural environmental featureswith two innovative products: The RSL 400 safety laser scanner and the OGS 600. RSL 400 combines safety technology with a high-quality measured value output for AGVs in one compact device. This ensures reliable Protection and navigation possible. The speed of an automated guided vehicle system is safely reduced by monitoring several protective fields in parallel.

Alternatively, the navigation of automated guided vehicle systems for the transport of materials and goods can be solved using flexible, optical lane guidance. For this purpose, the company offers the OGS 600 a compact sensor. By detecting edges and sending control signals to the drive, it is possible to the track is optically guided so that driving can be easily automated. The Routes of the driverless transport systems can be flexibly adapted using optimised track belts. The compact design of the OGS 600 and its low minimum distance to the floor of just 10 mm enable it to be used in a wide variety of applications. Integration even in flat vehicles.

Leuze electronic at the LogiMAT: Hall 3, Stand B69

Source: Leuze electronic