Minebea Intec presents a new generation of load cells that offer high measurement accuracy and speed thanks to electromagnetic force compensation. This technology is used particularly in dynamic checkweighers.

Minebea Intec has launched a new generation of load cells onto the market. These are based on the Electromagnetic force compensation technology (EMF), which is known for its high accuracy and fast weight detection. This technology was developed at the Aachen centre of excellence in collaboration with the parent company MinebeaMitsumi and integrated into the first products in the WZEDP series.

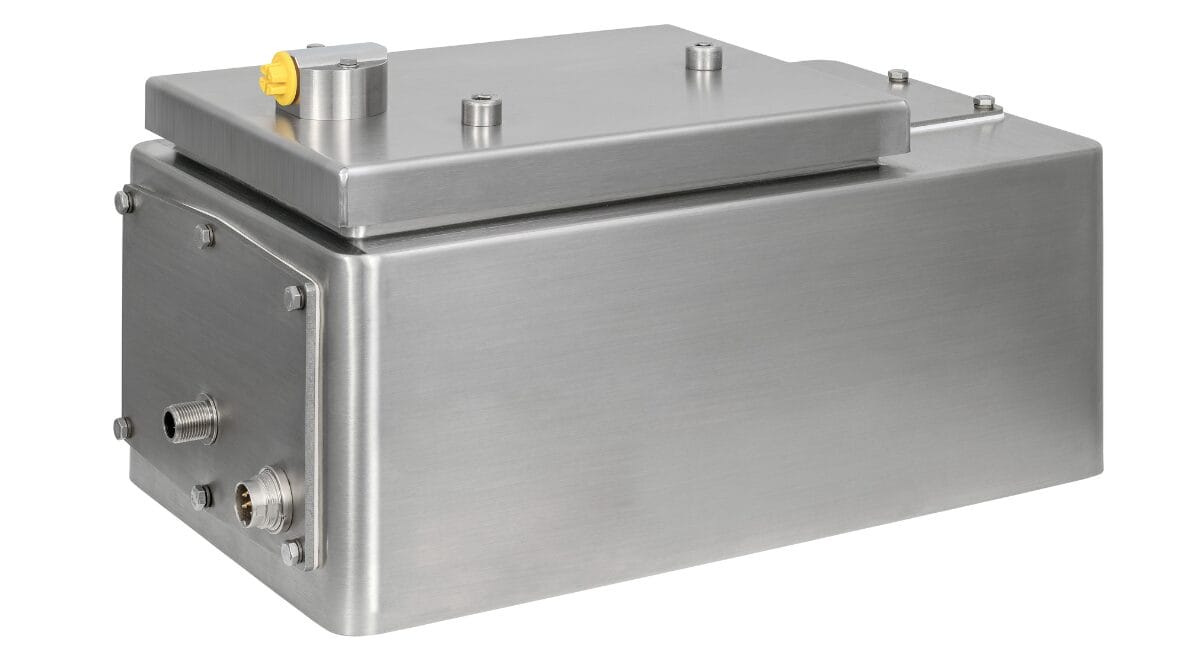

Industrial EMF load cells are designed for applications that require High demands on measuring accuracy and throughput such as dynamic checkweighers. Here, a load cell records the weight of products travelling on a conveyor belt and evaluates this data. The new WZEDP product series from Minebea Intec was perfected in Aachen. Following the acquisition of the Industrial Technologies division, the development of the central electronics and the so-called monolith, both of which are core elements of the new EMK load cells, began there.

Monolithic sensor base body with 3D milling technology

The monolith, a base body made of high-strength aerospace aluminium, is milled from a block of material and then measured. It forms the The centrepiece of the load cell and is decisive for the measuring performance. The monolith contains levers that are thinner than a hair, which leads to the Load cell precision contributes to this. A team in Aachen developed a system with multi-transmission levers that is manufactured by a local supplier. This design eliminates screw connections along the force transmission path, which prevents measurement errors such as drift. The three transmission stages allow high preloads so that the product weight can be compensated with a minimum electromagnetic force. This reduces heating of the measuring system and enables up to 10,000 calibratable steps across all measuring ranges.

The successful development process led to the purchase of a 5-axis milling machine and the establishment of mechanical production with pre-assembly of this EMK sensor at the modern production site in Košice. This site is managed centrally by Minebea Intec Aachen. Once the add-on parts such as the magnet system, coil and position detector have been assembled, the Sensors subjected to comprehensive tests.

At the Aachen plant, the pre-assembled sensors are completed with electronics, housing and other add-on parts. The complete load cells are assembled in a Climate chamber tested over the entire temperature range. In addition to the zero point measurement, weights are automatically applied at different temperatures in the climate chamber. The data obtained is converted into correction parameters and stored in the electronics of the load cell. Finally, the temperature-compensated load cell is checked again against metrological data.

The specially developed electronics enable fast, dynamic weighing. Digital measuring algorithms provide ready-to-use weight values with a high data rate of up to 2,000 measured values per second, which enables quasi real-time monitoring allowed. These load cells can be combined with a conveyor belt that fulfils special accuracy requirements to ensure reliable dynamic measurement. The weighing belts are also developed and built in Aachen. The EMK load cells from Minebea Intec are now also available for OEM applications for direct machine integration. Customers therefore benefit from the entire expertise of the development centre in Aachen.

Source: Minebea Intec