An inductive quick-charging system, a multi-format packaging system and a system for automatically and anonymously analysing manual work processes are the three innovative top achievements that will receive the „LogiMAT Best Product 2020“ award this year.

An independent jury of scientists and journalists selected A total of 115 applications received three worthy award winners who rightly honour the name „LogiMAT Best Product“. They fulfil the competition requirements in an outstanding manner: Increased productivity, cost savings and rationalisation.

With their products, the award-winning companies contribute to secure processes, easier adaptation to changes, improved efficiency and ultimately increased productivity in logistics.

Due to the accelerated spread of the coronavirus in Germany, LogiMAT 2020 had to be cancelled last week by order of the authorities. cancelled become.

„For us as LogiMAT organisers, it is very important to announce the three award winners to the general public today on what was originally the first day of LogiMAT, and in doing so to honour their achievements. Recognising top performance. All three more than deserve it. Of course, we will personally present the „LogiMAT Best Product“ award and hand over the medals and certificates at a later date in a suitable setting.“

Michael Ruchty, LogiMAT Exhibition Director from the Munich-based organiser EUROEXPO Messe- und Kongress-GmbH

Category: Picking, conveying, lifting and storage technology

In the „Picking, conveying, lifting and storage technology“ category, the prize goes to the Start-up Wiferion GmbH for its inductive fast-charging system etaLINK 12000. The scalable energy solution is the world's first contactless battery charging system with an output of 12 kW and an efficiency of 93 per cent.

etaLINK 12000 enables the Intermediate charging („in-process charging“) of the lithium-ion batteries of automated guided vehicles (AGVs), industrial trucks and mobile robots. Charging processes can thus be flexibly integrated into intralogistics processes. The scalable energy solution is the world's first contactless battery charging system with an output of 12 kW and an efficiency of 93 per cent.

Intermediate charging keeps the energy level of the vehicles at a constantly high level. The result: in most cases, the battery capacities can be more than 30 per cent smaller for the same vehicle performance, thus significantly reducing the acquisition costs in the battery sector.

Category: Identification, Packaging and loading technology, Load securing

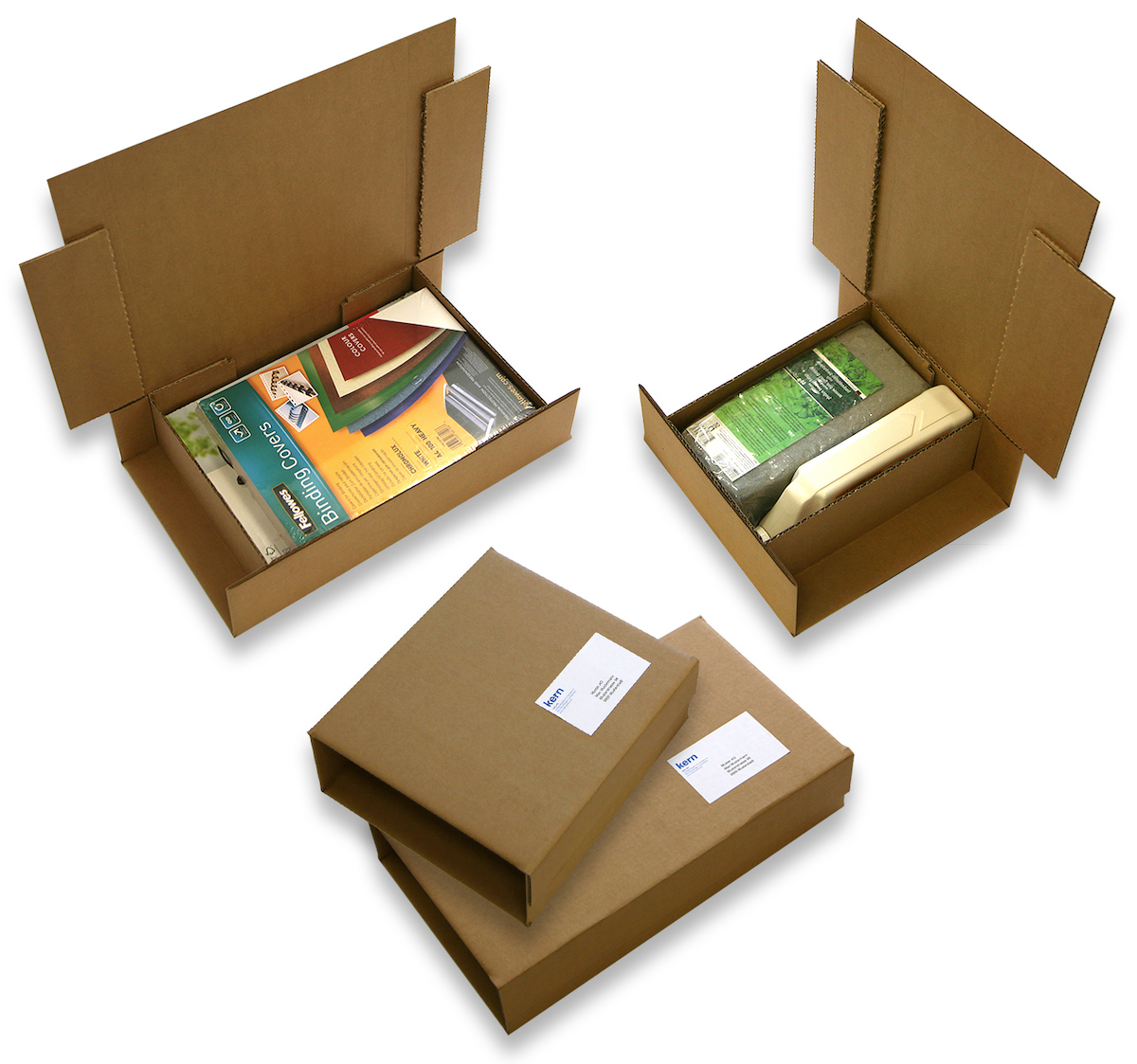

In the „Identification, packaging and loading technology, load securing“ category, the prize goes to Kern AG for the multi-format packaging system PackOnTime 2box for customised packages.

Kern AG has hit the ravages of time with the „PackOnTime 2box“ concept. Optimised and automated logistics ensure the smooth dispatch of a wide variety of items. This requires clever packaging concepts and systems that provide the packaging at the required time.

The multi-format packaging system fulfils the requirements „Smart Pack - Made On Time“. Orders of all kinds (single and multiple items) are measured using a 3D process and then placed in the custom-fit packaging.

Category: Software, Communication, IT

In the „Software, Communication, IT“ category, the prize goes to the Start-up MotionMiners GmbH for the world first Manual Process Intelligence (MPI). This AI solution enables manual work processes to be analysed automatically and anonymously.

Conventional analysis methods, which are usually carried out by trained process engineers using a clipboard and stopwatch, are extremely complicated and time-consuming. With the new MPI, employees from a wide range of fields are equipped with mobile sensors and a smartphone. Localisation takes place anonymously via Mobile sensors (wearables) and miniature radio transmitters (beacons).

The beacons placed in the relevant warehouse areas, in conjunction with the smartphone, are used to locate the employees. The individual work steps are automatically reconstructed from the process data and made available for further analysis. The data collected in this way is analysed by a highly specialised artificial intelligence, the „MotionMiners-AI“, which is equipped with a pattern recognition solution. all data processed on the basis of machine learning. The measurable savings in previous projects were ten to 15 per cent with peaks of 40 per cent.

Source: EUROEXPO Messe- und Kongress-GmbH