Label production doesn't have to be complicated. With the right hardware, software and advice, even newcomers can produce complex labels, such as window labels, efficiently in short runs. Digital processes in the print run and finishing help to automate production and avoid costly errors.

Although forecasts indicate a significant increase in demand, print service providers are currently facing a dilemma: on the one hand, the Labels are becoming increasingly complex and diverse, while print runs are decreasing and shorter delivery times are required. become more important. On the other hand, it is becoming increasingly difficult to find and retain qualified employees. Many print shops even cite this shortage of skilled labour as the biggest challenge.

Digital workflows as problem solvers

However, digital printing, automated workflows and modern finishing technologies can make the seemingly impossible possible. So allow digital printing machines to produce short runs and automatic job changes. Digital workflows prepare the print data and send the right job to the right machine at the right time without the need for operator intervention. Modern finishing options enable automatic configuration of processing with minimal operator intervention and waste.

Nevertheless, it is not always easy to seamlessly connect and optimise the individual components of the production process. Setting up an efficient printing solution may require a consultancy approach, such as that offered by Xeikon and its Solution Services (XSS). The XSS team specialises in production lines that require more than standard products and in which processes need to be optimised across multiple components. A good example of how the efficient production of complicated products can be supported at the customer is label printing for pharmaceutical retailers.

Fully automated production of pharmaceutical labels

Automation is most efficient when it starts well before the actual full-colour digital printing press and encompasses the entire production process. For example, it is possible to integrate the digital front end (DFE) of a Xeikon press into a company-wide enterprise resource planning (ERP) system. Depending on the incoming product orders, the print jobs are created automatically every day to produce exactly the labels required in each case. With the help of software developers, Xeikon can also programme solutions that integrate into the customer's ordering system and create JDF (Job Definition Format) job tickets and print files without any operator intervention.

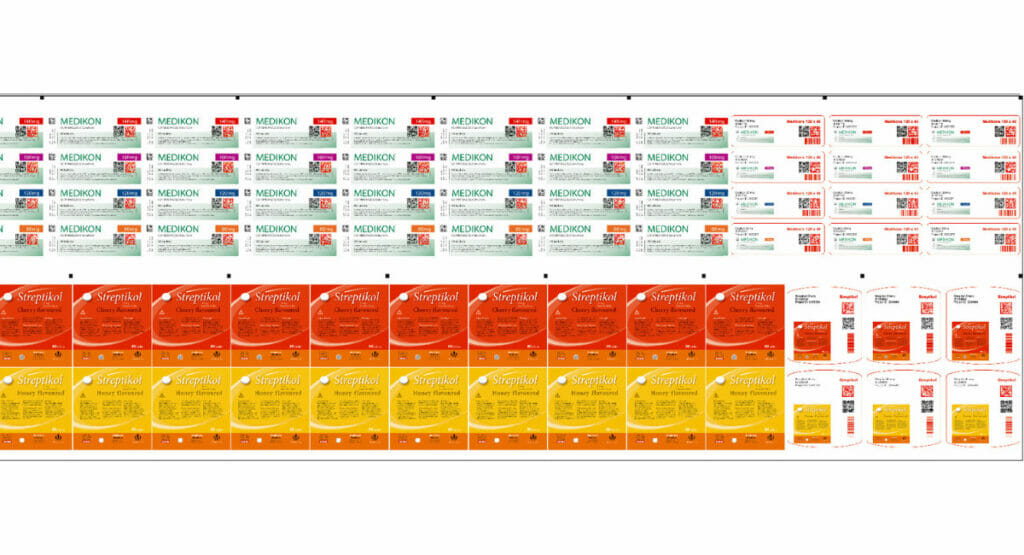

But even without ERP integration, many software tools are available to streamline and optimise print production. The software in the Xeikon DFE sorts and collates the print jobs to optimise the production process. maximise the use of the press format and finishing configuration, while also taking delivery deadlines into account. The final arrangement of the labels is determined during the step-and-repeat process. If required, the labels are assigned additional variable data. Due to the very small quantities, it is often necessary to print in several lanes in order to utilise the productivity benefits and print width of the Xeikon printing press and to make further processing more efficient. This optimisation is performed by the Varilane software of the Xeikon DFE.

To automate the downstream processes, the DFE creates a specific order identifier (ID) and inserts a Data Matrix Code (DMC) into each lane at the beginning and end of the order. This data is used for the automatic configuration of the processing and control systems and enable the continuous monitoring of a process., in which operator intervention can be completely or partially dispensed with. Finally, Xeikon's Vectoriser software creates the die-cutting contour files for the laser die-cutter and stores them on a server ready for retrieval. All these processes run automatically to reduce the workload of the pre-press department and machine operators and to ensure that all jobs are processed without errors.

Efficient punching of printed material

The printed label rolls are loaded into one or more laser die-cutters. Their use has proven to be the most efficient solution for the automatic labelling of printed roll material. At the beginning of each new job, the laser punch reads the DMC code in each material web to automatically load the correct punch file. The laser die-cutter can also switch dynamically between different label shapes on the material web without die-cutting moulds, tools or manual intervention.

There are applications where the package contents must be recognisable in a non-printed window. The However, the window cut-out sometimes also fulfils a decorative purpose, as it can significantly enhance the visual effect of the label. In some cases, it is sufficient to simply punch out a cut-out from the label material. A transparent film may also be required if the label would otherwise be too unstable or additional protection is needed. For this application, a double laser punch is the best solution, as some parts of the label are punched out before lamination and other parts only afterwards. have to be loaded. The MatrixCode readers in the laser punches ensure that the correct contour file is always loaded automatically. Using the contour punching files created by the Vectoriser software, the laser finisher calculates the layer thicknesses in order to automatically adjust the laser power in the two punchers. All changes are made immediately and without waste. In conventional production, a window label would involve a considerable amount of set-up work and a large volume of waste. In addition, a highly qualified operator would have to be on site.

Automation takes over manual processes

The XSS team provides support in selecting the optimum hardware and determines the automation potential of all individual processes. In addition, it assumes overall responsibility for the production line vis-à-vis the customer and is also the central point of contact for all procurement issues relating to configuration and operation.

Xeikon's label production lines, such as the line for the pharmaceutical industry, must be Produce complex labels in very short runs and check all labels produced at the same time. Several production lines have already been installed at re-importers of pharmaceuticals who previously had no experience in production printing. Although these users had neither experienced personnel nor production expertise, the lines were up and running within a few weeks of installation. It has been shown that customers with no experience in a specific print market can successfully invest in a print production line in co-operation with the XSS team and operate it efficiently, even for complex end products.

More news from the magazine

Traffic lights prevent bottlenecks

Three applications, one solution

Translucent paper seal labels for pharmaceutical packaging

Packaging machine manufacturer in flow