Experts from the various Coesia companies will be presenting solutions for pharmaceutical production at Achema 2024. Innovative technologies that meet the complex requirements of pharmaceutical production will be the focus of the trade fair presentation.

Visitors will learn how advanced solutions can improve their manufacturing processes. Technologies for optimising all aspects of pharmaceutical production will be on display. With its expertise in packaging and the automation of complex processes Coesia manufacturers to master the challenges of their customers.

„At Coesia, we understand the challenges facing the pharmaceutical industry. Our presence at ACHEMA 2024 demonstrates our commitment to improving manufacturing processes through innovative and integrated solutions tailored to these challenges.“

Alessandro Parimbelli, CEO of Coesia

On the Achema In 2024, Coesia will introduce a range of advanced technologies to optimise pharmaceutical manufacturing processes. For example, the GF linear inspection machine for IV softbags (LBI): this machine performs thorough inspections with high-resolution cameras and robotic handling and is also characterised by a design that is optimised for the optimised for efficient use in confined spaces and significantly increases operational agility.

Hapa's Blisterjet Agile enables the precise customisation of blister packs at a late stage through the use of advanced digital printing technology, which can process both spot and full colour projects (CMYK). This increases flexibility and shortens time to market. The integrated vision inspection system ‚Vision Secure‘ controls the print quality at a high level. FlexLink's robotic sorting ring combines precision robotics with advanced conveying solutions and provides high accuracy in product sorting and buffering, which is critical for high-throughput production environments.

MGS develops systems for seamless secondary packaging processes. The focus here is on a modular design, to enable future scalability and integration into various production lines. PHS-65 from Enflex is designed for the highly efficient production of stickpacks. The Multi-lane system not only fulfils the strict industry standards, but also features advanced functions for optical character verification and recognition, improving both throughput and compliance.

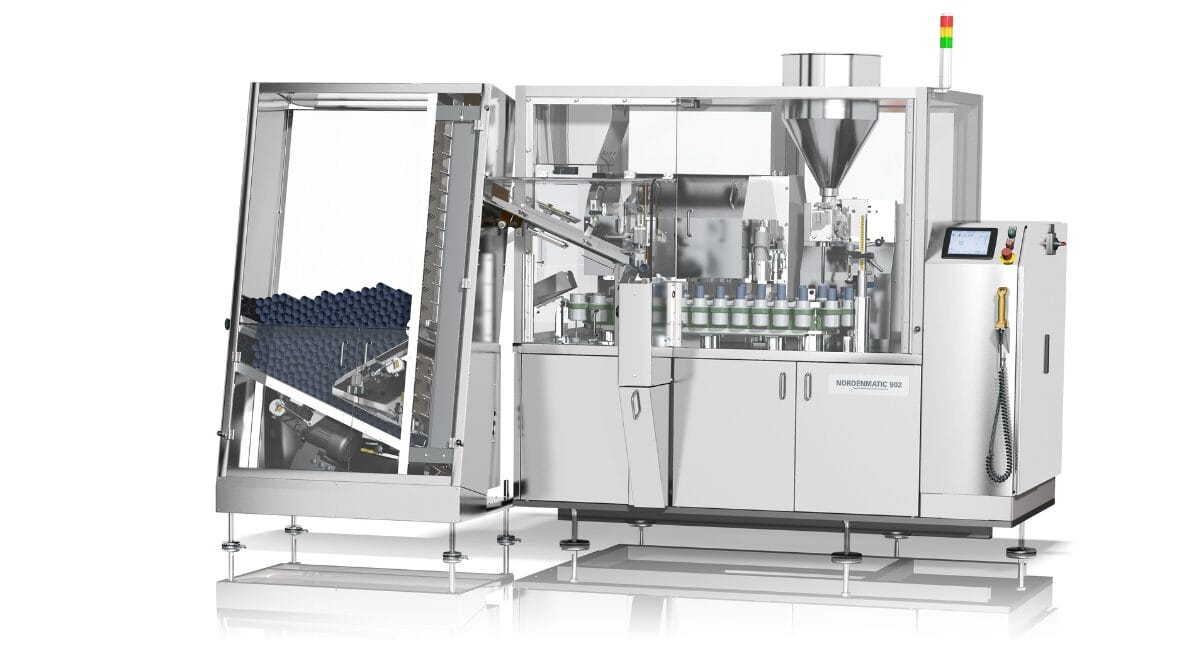

PH-11 from Enflex is a sachet machine known for its operational flexibility and hygiene. The system supports the production of pharmaceutical powder products in a GMP-compliant environment. It offers functions that fast production changeover and improve traceability. Norden shows NM 902. Precision and adaptability well-known tube filling machine NM 902 was developed to reduce downtime and maintenance. With its ability to process a wide range of tube sizes and specifications, it is an invaluable asset for companies looking for ways to optimise their packaging lines.

Coesia Digital is a comprehensive approach that integrates advanced digital platforms and customer-centric services to drive operational excellence. Platforms such as OptiMate, PerforMate, UltiMate and HyperMate improve interaction with the machines, real-time monitoring, AI-supported optimisation and comprehensive management of production processes. Coesia Digital enables our solutions to deliver maximum efficiency and value.

The customer service offering is embedded in the overall offering and offers Proactive and continuous support from the start of the project to routine operation. This approach helps to optimise the overall effectiveness of the systems and minimise the total cost of ownership so that customers can get the most out of their investment.

Source: Coesia Group

Coesia at Achema: Hall 3, Stand D73