The global cutting-die manufacturer Marbach is presenting its top news at drupa. In addition to the topics of digitalisation and sustainability, everything at the Marbach stand will revolve around the latest product innovations.

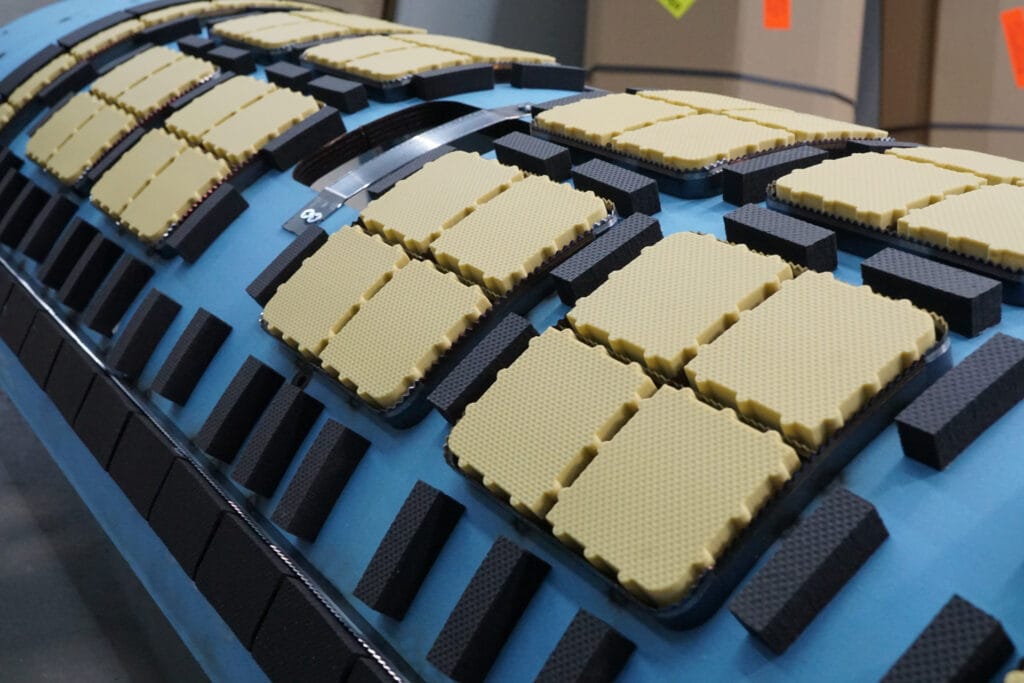

In addition to its new Connect|M system solution for more digitalisation in die-cutting and best machine performance, Marbach is presenting the DZL|plate digital zone levelling system. This ensures with its innovative coating now even longer for reduced make-ready times when die-cutting packaging. Also on show: the marbacover technology for optimum results when die-cutting corrugated board and the new marbaject high-performance rubber for maximum machine speeds. In addition, Marbach will be presenting the new, lightweight and high-precision carrier plates duramar|alu and solidplate|alu as well as a Special tool for punching honeycomb cardboard.

Safety during the stripping process - that's what the Marbach bottom pin grid offers. Especially in combination with the new precision bottom pin: thanks to its special design, it is not only highly precise, but also very wear-resistant. For long-term Smooth stripping processes and 100 per cent zero waste.

With depanelling the topic of stacking quality The Marbach alublanker plays a major role not only for high machine speeds, but also for the further processing of the packaging blank. With the Marbach alublanker, customers are on the safe side: its high-precision design in aluminium ensures perfect pile formation, short set-up times, high machine speeds and high packaging quality. In addition, all Marbach blanking tools will be even better equipped in future: with new, long straight levellers and stable guide elements. This ensures optimum stack quality and even better performance in the blanking process.

Marbach offers a comprehensive portfolio in the field of embossing. In order to make the set-up of embossing even faster and more efficient in future, Marbach has developed a depositing system for embossing. This also includes special embossing underlays made of paper. The new depositing system reduces make-ready times during the embossing set-up process.

Source: Marbach

Marbach at drupa 2024: Hall 10, Stand C28