Koch Pac-Systeme GmbH launched its newly developed KBS-C medplus blister machine for small to medium batch sizes at the end of March. We asked Markus Böhringer, head of the medical technology market application area, about the highlights of the new machine, special target groups and the unexpected challenges posed by the coronavirus crisis when introducing the new technology.

With the KOCH medplus brand, the company offers its customers in the medical technology sector customised machine solutions for the Packaging of sensitive medical technology and pharmaceutical products. The machine concept is based on many years of experience in this field of application. The special machine manufacturer based in Pfalzgrafenweiler is proud of this next generation of machines.

pj: Mr Böhringer, what are the main features of the KBS-C medplus blister machine?

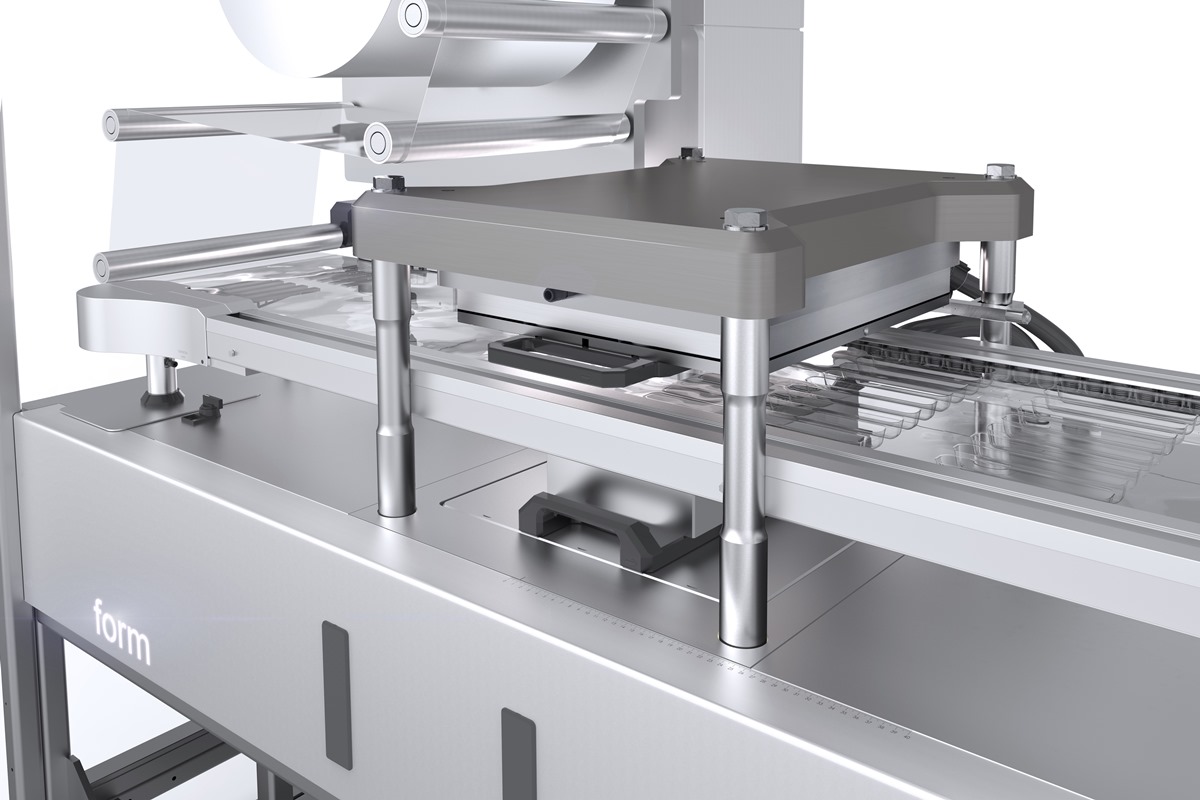

Markus Böhringer: The machine, which was specially developed for medical technology applications, combines several highlights. Particularly noteworthy is the Very compact design of the machine. At less than seven metres in length, the KBS-C medplus processes formats that were previously reserved for larger systems.

This compactness is complemented by a simple structure and easy set-up, which enables quick relocation, e.g. to the clean room, and a fast production start. For customers in the medical sector in particular, it is essential that a machine fulfils all the requirements for cleanroom production. Packaging of sensitive products is fulfilled. The design for the Cleanroom use up to ISO class 7 and risk classes IIa, IIb and III designed. Whether for cleaning, adjustment work or mould changes, all areas of the machine are easily accessible and the entire packaging process is clearly visible to the operator through window doors and drive units below the process level.

pj: For which users was the innovative machine concept developed? And why at this point in time?

Markus Böhringer: The KBS-C medplus is characterised above all by its innovative and flexible machine concept. It was not developed by us for a specific, limited group of customers, but covers a wide range of applications thanks to its flexibility. Broad spectrum from medical technology to pharmaceuticals from. Whether syringes, instruments, surgical and treatment sets, medicines or needles. The target market is small to medium batch sizes, but the machine is also suitable for the production of larger batches thanks to the unique ratio of the footprint to the mould area (380 x 350 millimetres).

When developing the concept, we focussed above all on a quick batch change The KBS-C specialises in a wide range of functions: from a quick format change to fast film width adjustment and changing the feed length. This makes the KBS-C particularly interesting for customers who have to change batches frequently and want to reduce downtimes.

pj: Would you like to emphasise details?

Markus Böhringer: Three new developments in heating, forming and sealing guarantee excellent packaging quality: Smart Heating, Smart Forming and Force vectoring. In the process Smart Heating, for which we have the patent, the heating energy is precisely dosed and, in combination with the moulding process Smart Forming reduced film consumption. The innovative Force vectoring enables optimum control of the sealing quality. These processes result in perfectly formed and sealed blisters. All commercially available film materials can be used. For example, PET film or PA film as the forming film and Tyvek®, paper, PET film or PA film as the cover material.

As the first machine to Specially designed for medical technology applications It is also a milestone for us because it closes a gap in the KOCH machine portfolio between the smallest KDT rotary table and the next largest KBS-KF.

pj: What impact does the focus on applications in medical technology have on the „structure“ of the company?

Markus Böhringer: In order to take full account of its increasing importance, KOCH will also be realigning its corporate structure. Focus on the medical technology application area organisation. The previously joint application area of consumer goods and medical technology will be divided into two independent organisational areas. In this way, we want to bring even more focus and power to the individual areas and provide our customers with even more specific support.

pj: Were there any effects on the „market launch“ due to the current restrictions? How did your company solve the challenges/problem?

Markus Böhringer: Like all companies, the coronavirus crisis has presented us with a number of challenges. We recognised very early on that the situation was coming to a head and that the timing would coincide with the market launch of the KBS-C. We had originally planned a launch for 10 March 2020. Exclusive presentation planned as part of our global sales conference.

However, as the safety of employees, partners and customers is always a top priority for KOCH, we have decided to install the machine as part of a digital conference to present. Only the sales staff from Pfalzgrafenweiler were live on site, international partners were connected via video conference and the practical part on the packaging machine was realised directly on the new machine using digital service glasses.

Following the cancellation of the leading trade fair interpack, there will also be Further digital alternatives at KOCH. An alternative to the classic trade fair presentation is currently in the starting blocks in order to organise the further market launch of the new machine generation. We will be going public with this in the next few days.