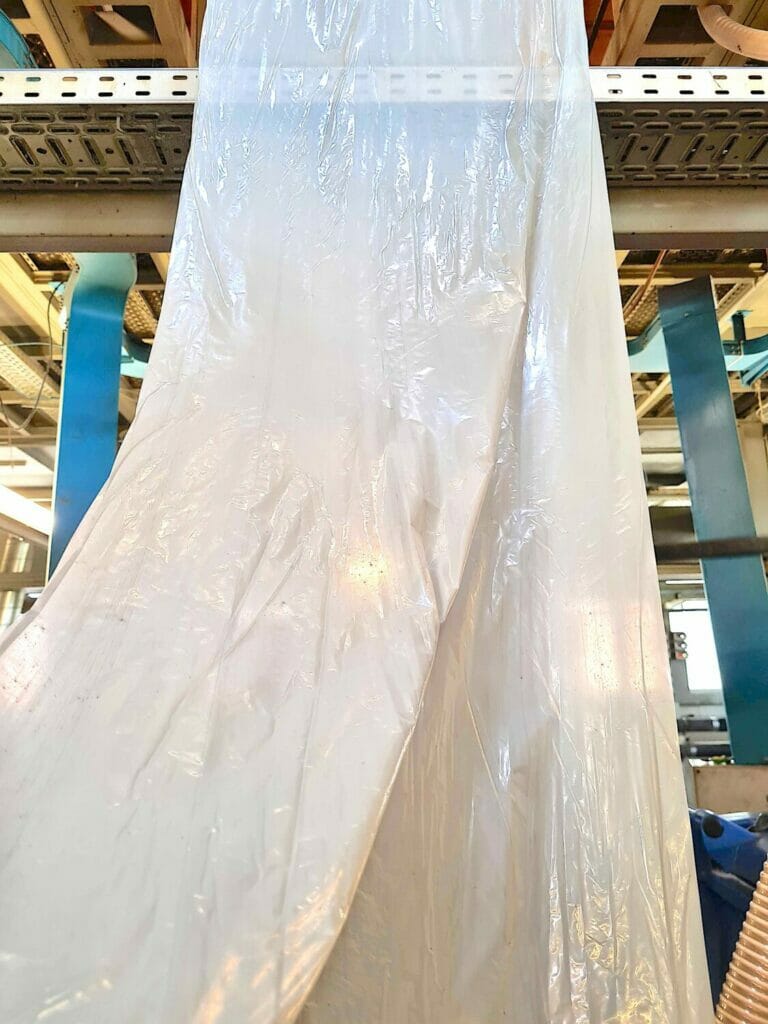

With a new separation process, Pla.to enables a material cycle for multi-layer food films. Based on a simple and resource-saving technology, the system also enables the economical recycling of films with a low unit weight.

Developed by Pla.to the separation process as part of a joint research project with the Zittau Institute for Process Development, Circular Economy, Surface Technology and Natural Materials Research (ZIRCON) of the Zittau-Görlitz University of Applied Sciences. It makes a contribution to this, to recover polyolefins for sustainable recycling and to close the material cycles of the corresponding polymers.

The process is based on two stages: In the first step, a new conditioning process changed the aerodynamic properties of the single and multi-layer films to varying degrees. This allows the materials to be classified in the air classifier in the second step. To enable this separation, the company has adapted the separator to the materials to be processed and optimised it for low bulk densities.

The process was tested on real material mixtures such as the film fraction 310 of the Green Dot from the post-consumer sector. The polyethylene (PE) recovered in this way could not only be turned into a reusable granulate, but also successfully used for blowing new films. be recycled. This closes the cycle from film to film.

Plastic films still dominate food packaging. They keep the contents fresh and protect the flavour and appearance from environmental influences. High-performance laminates consisting of several layers of film that are bonded together are used for this purpose. As a result, they combine different protective properties with minimal use of material. These However, multilayer films are problematic in terms of recyclabilityNevertheless, their market share has increased in the past.

In contrast to single-layer materials such as films made from polyolefins, for example polyethylene (PE) or polypropylene (PP), they cannot simply be melted down and recycled, as the different polymers are generally immiscible. This is why downcycling usually takes place, which only allows recycling companies to achieve a low added value.

Source: Pla.to

Pla.to at the K trade fair: Hall 9, Stand D17

More news from the recycling sector

New PET film line launched in Wiesbaden

High recycling rate for beverage cans in Europe

Starbucks strengthens cup recycling

AVU criticises lack of recycling incentives