Medipack, Schaffhausen/Switzerland, is introducing a new, more sustainable thermoforming film using Eastar 6763 Renew from Eastman. According to the company, the material offers the usual performance of medical packaging while reducing the environmental footprint.

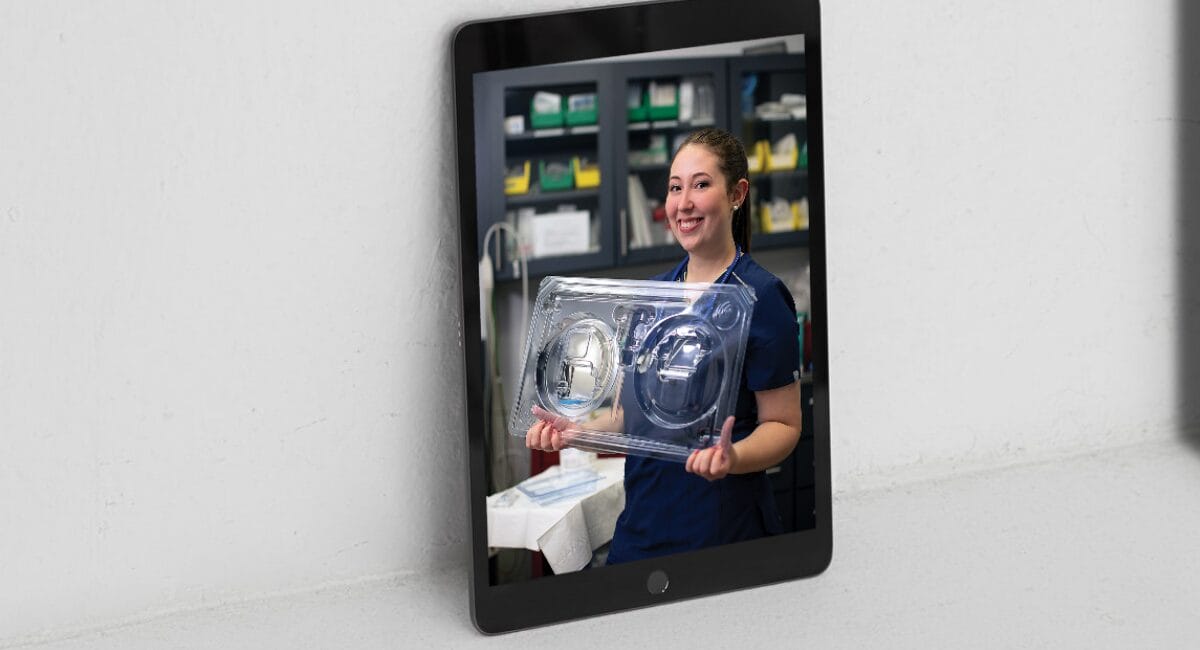

Medipack is integrating Eastar 6763 Renew into its new medpetg 6763 rn thermoforming film as an alternative material to the previous plastic. According to the company, the Eastman solution contains up to 50 per cent certified recycled content, which comes from waste that is difficult to recycle using the mass balance process. This reduces the use of virgin material and relieves the burden on waste streams. The film can be used in the production process without any adjustments, as the material has the same properties and certifications as the conventional version.

Drop-in material with identical performance

Eastar 6763 Renew is intended to enable companies in the medical technology sector to make a direct switch. According to Medipack, the material continues to meet the requirements for transparency, durability and sterilisability that are necessary for pharmaceutical and medical applications. As no new approvals were required, Medipack was able to introduce the more sustainable film without time-consuming certification processes.

Contribution to the circular economy in medical technology

According to Eastman, the recycled content is based on the company's molecular recycling technology, which converts plastic fractions that are difficult to recycle back into raw material quality. This opens up new possibilities for sterile barrier packaging, which previously could hardly contain any recycled material. The companies see this as a step towards further advancing circular approaches in medical technology.

Source: Eastman Chemical Company