Koenig & Bauer MetalPrint has received the Metpack Innovation Award in Gold for the innovation „MetalControl“. Further awards went to the companies Actega and Can Man. A total of 19 exhibitors submitted 31 entries.

The independent international jury of experts determined the winners of this year's METPACK Innovation Awards on the basis of several criteria. Innovative content, cost savings, quality enhancement and sustainability were decisive for the assessment using a points system. The applicants were in a close neck-and-neck race.

Finally, the Koenig & Bauer MetalPrint GmbH led the field. The system provider for printing and coating lines, dryers and exhaust air purification based in Stuttgart won the jury over with a new closed-loop colour control system convince. „MetalControl“ scans each sheet and measures the colour density. The results are digitally transmitted to the control panel, evaluated and the colour zones are automatically corrected.

The award-winning innovation from Koenig & Bauer MetalPrint is One hundred per cent closed-loop colour control within the press, which guarantees maximum colour stability and consistency regardless of the operator. Manual adjustments are no longer necessary. Complaints, test prints and set-up times are reduced.

„ROTARflow“ in second place

Actega GmbH from Wesel has a new digital solution which monitors the amount of sealant applied to lids by rotating liners and adjusts it immediately as a result. „ROTARflow“ recognises any deviation from the target value of the dry film weight and automatically changes the pressure and needle stroke accordingly. Downtimes and manual intervention are eliminated. The production data is also available from any digital device. „ROTARflow“ reduces costs, material and time usage and increases quality at the same time.

„PowerCUT SuperFLEX“ honoured with bronze

With the PowerCUT SuperFLEX duplex cutting machine from the Swiss company Can Man fully automatic format changes are possible in a world record time of 15 minutes. In addition to the enormous time savings, the innovation has another advantage: damage to cutting tools is avoided by eliminating manual operation. The machine also offers maximum flexibility for cutting all formats with high cutting accuracy

Platform for the global metal packaging industry

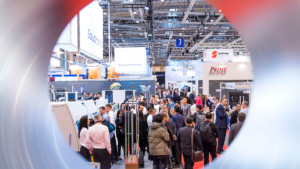

Decarbonisation, resource efficiency and digitalisation were the dominant themes at this year's Metpack, which took place from 2 to 6 May. Around 6,500 trade visitors from all over the world came to Messe Essen over the five days of the fair. They experienced pioneering technology, new products and further developments for the production, refinement and recycling of metal packaging. The world's leading trade fair for metal packaging recorded 313 exhibitors at its tenth edition - a slight increase.

„The industry's major goal is to use as few resources as possible, reduce costs and improve quality at the same time. This can be achieved through new technologies and processes. At Metpack, trade visitors had every opportunity to familiarise themselves with the latest developments and experience innovations at first hand. The willingness to invest is high.“

Wolfgang Niemsch, Chairman of the Metpack Committee

Source: Essen Trade Fair

Metpack - More news

Essen under the sign of Metpack 2023

Programme of the Metpack Conference

Henkel: Sustainable metal pretreatment

Trends in metal packaging