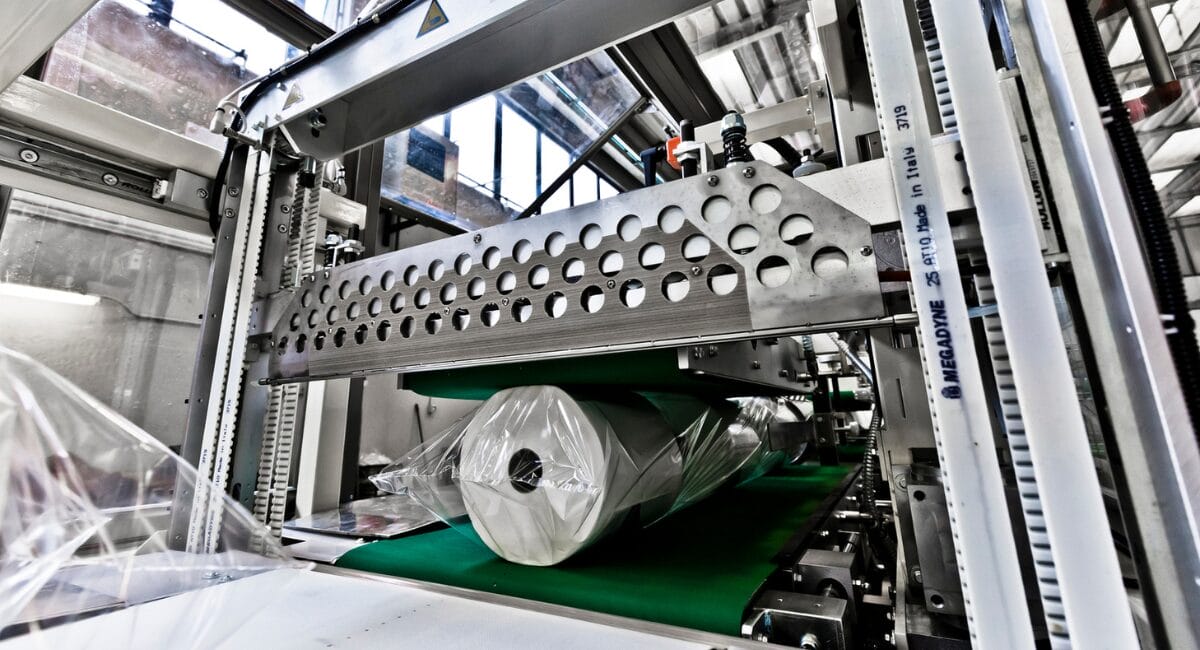

With the new AL 80 Maxi, Microline is launching a further development of its established horizontal packaging machine onto the market. The Italian company is thus responding to the increasing demands for flexibility and sustainability in packaging technology.

Microline specialises in automatic end-of-line systems for tissue, food and cosmetics. The new AL 80 Maxi impresses with its increased capacity and versatility: rolls with diameters of up to 280 mm can be processed in single or double packs. Depending on the configuration, the machine achieves up to 65 packaging units per minute - with consistently high precision and packaging quality.

Microline places particular emphasis on adaptability. The machine supports a wide range of packaging materials - from LDPE and POF to monomaterials and environmentally friendly alternatives - and is therefore suitable for both traditional and sustainability-orientated production environments.

The AL 80 Maxi also sets new standards in terms of efficiency: A Optimised process without material waste reduces energy consumption, while the option of remote monitoring and diagnostics reduces operating and maintenance costs. Thanks to its compact design, the machine can also be easily into existing production lines.

With the AL 80 Maxi, Microline is positioning itself as a Technological partner for the tissue market. The new model combines speed, energy efficiency and material diversity and thus represents a consistent further development of the successful AL-80 series.

Source: Microline