Global company Milliken & Company, together with machine manufacturer Erema and German environmental services provider PreZero, will be demonstrating the recycling of regrind at this year's K, using a performance additive from Milliken.

At the trade fair from 19 to 26 October in Düsseldorf, Austria-based machine manufacturer Erema will be presenting its technology in its entirety. In the Erema Circonomic Centre on the outdoor area of the trade fair (OA/-CE03) the company will be demonstrating the recycling of regrind from the German environmental services provider PreZero in a live demonstration (Hall 8B/A57).

For the demonstration, the partners use regrind collected by PreZero from post-consumer recycling (PCR) sources. As an example of a true value-added partnership, PreZero then utilises its formulation expertise in conjunction with Erema's recycling technology and Milliken's Hyperform HPN additive to produce PP recyclate. Erema's machine technology delivers odour-optimised rPP granulate directly from contaminated PCR regrind.

Additives bring recycled material closer to virgin material

Hyperform HPN additives refine rPP by improving its physical properties and also reducing cycle times during processing. They also ensure better dimensional control and crystallisation stability after injection moulding.

The use of Milliken's HPN nucleating agent brings the performance of rPP closer to that of PP virgin material. Or as PreZero puts it: „With our recycling activities, we give seemingly worthless old material a new lease of life.“

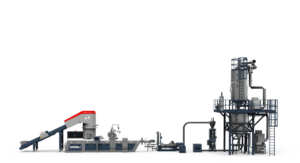

During K, Erema will be demonstrating its patented Intarema TVEplus RegrindPro extruder system with ReFresher technology in operation. The system specialises in recycling materials that are difficult to process, such as heavily printed films and very moist regrind. This is made possible by ultra-fine filtration, thorough melt homogenisation and high-performance degassing in a single step. In accordance with the proven basic principle of TVEplus technology, melt filtration is upstream of degassing in the extruder.

Source: Milliken & Company

Further trade fair news on the K

Aimplas showcases innovations in circular and bio-based plastics

Fraunhofer IVV recycling process keeps plastics in the cycle

Erema prepares plastic waste for chemical recycling

K 2022 has started