For Zünd, the focus is on digitalising and automating its customers„ value chain and thus increasing their competitiveness. To achieve this, the company's cutting solutions are becoming increasingly independent and autonomous. This year's entire presentation is themed “Performance across the board".

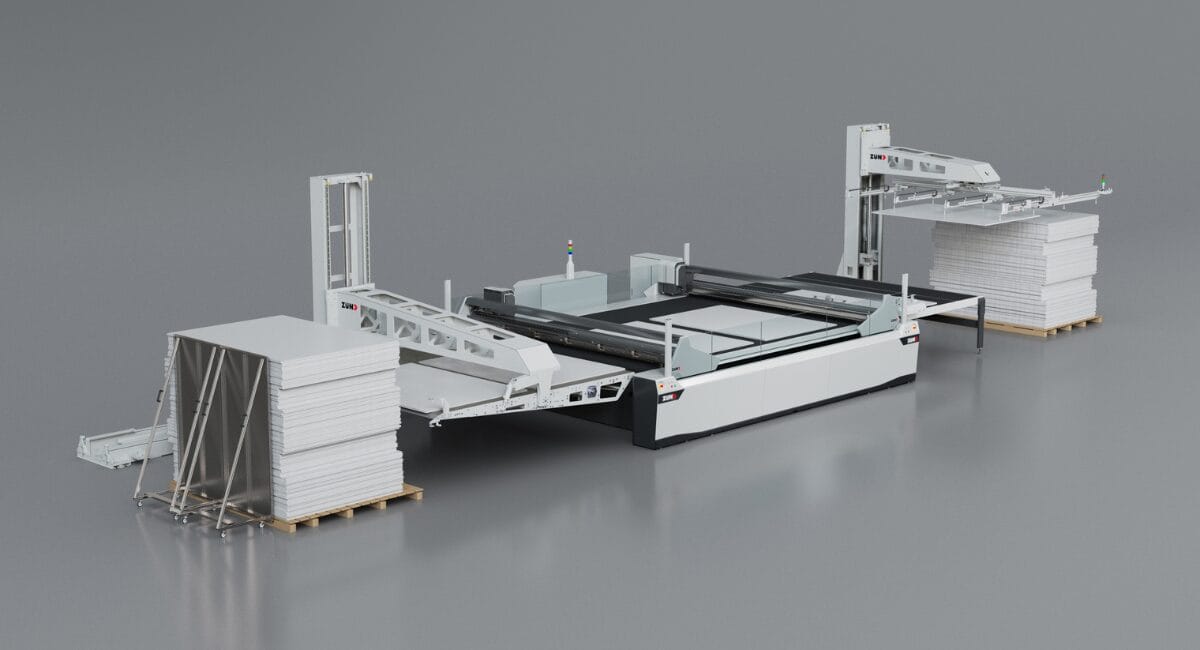

The new Q-Line generation of cutters in combination with the BHS180 board handling system and the integrated Undercam optical detection system will be premièred at the trade fair. The cutting solution sets new standards in industrial non-stop production and represents the highest level of automated digital cutting. The fundamentally new machine concept behind the Q-Line with BHS180 has redefined the performance limits in several respects and significantly improved production efficiency once again compared to classic die-cutting. The new substructure of the Q-Line is made of highly stable mineral casting. Even at high speeds, it ensures Maximum smoothness and precision in cutting. The production beams are made of carbon fibre-reinforced plastic. This makes them light and robust and enables high-precision cutting of demanding materials at top speed.

The company has a broad portfolio of solutions for productive cutting. How productivity and cost-effectiveness can be optimised with innovative options is demonstrated by Ignition among other things with the new sheet positioning extension with optional undercam for the third generation cutters. It was adopted as a technology transfer from the Q-Line with BHS180 and will be presented on site in combination with a Zünd G3 cutter. Visitors to the stand will be able to experience live how they can control robots and sort finished parts fully automatically. Zünd will also be showing the PortaTable 130 robot.

Zünd at drupa: Hall 9, Stand B 03