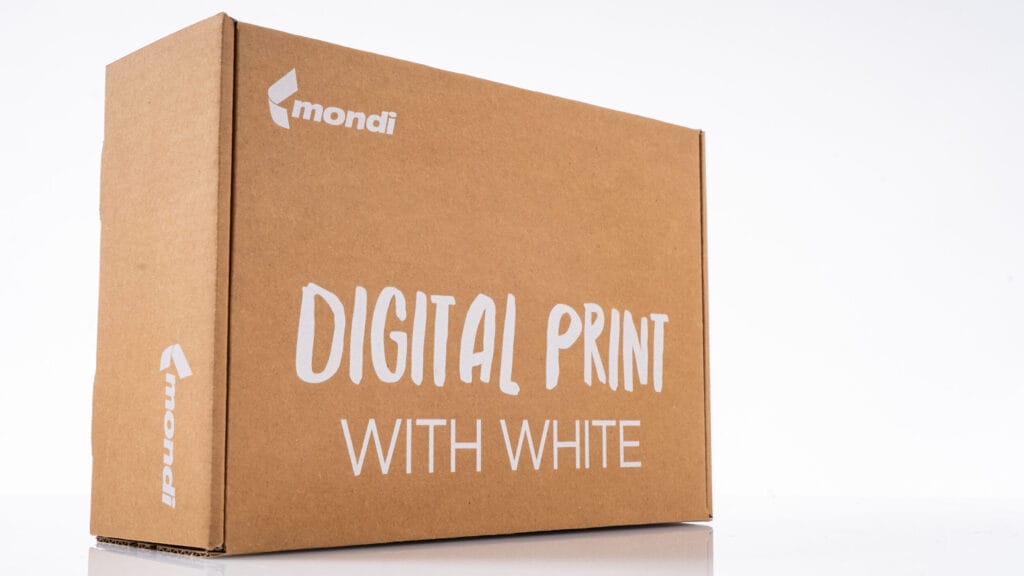

Mondi is adding the colour white to its six-colour digital printing for corrugated board packaging, creating new branding opportunities on brown corrugated board.

The innovation at the recently acquired site in Ebersdorf picks up on the growing trend of white printing on brown packaging. This enables bright, high-contrast designs that strengthen brand identities and promote sustainable, resource-efficient solutions that utilise the flexibility of this innovative technology.

The addition of white is More than just an additional colourIt opens up new possibilities in branding and packaging design. Thanks to the white underprint, colours, logos and motifs on brown corrugated board appear just as bright and rich in contrast as on white carrier material - a decisive factor for brand identity and recognisability at the point of sale.

In addition, the halftone printing Gentle gradients, differentiated shading and bevellingwhich create the impression of three-dimensional image effects. This creates brilliant, high-contrast print images and new possibilities for sophisticated packaging designs.

All colours used are water-based, tested and approved by Swiss Quality Testing Services (SQTS) - an independent, accredited testing institute for quality and product safety authorised for use on primary packaging. Thanks to data-to-print technology, clichés and printing plates are no longer required. Set-up and production times are reduced and new packaging designs can be realised more quickly and changed at short notice.

For marketing and in logistics and supply chain processes, digital printing, including the new white option, offers advantages that flexo and offset printing cannot provide. One key advantage is the ability to print consecutive bar, EAN and QR codes directly on the packaging. This eliminates the need to apply labels, which saves costs, time and resources. The circumferential printing of the codes also reduces potential sources of error during reading.

Medium and large quantities of the same design can be provided with different print images in a single pass, for example for seasonal, regional or event-related campaigns. Optimised splitting means that each print image only the quantity actually required is produced. This reduces storage costs and avoids surpluses.

Source: Mondi