Advances in personalised medicine are making therapies even more effective. This revolution in the pharmaceutical industry would not be possible without intelligent packaging solutions.

Pharmaceutical companies are currently conducting intensive research into highly complex biologics and other Speciality drugs for personalised medicines. These new therapies are intended to help patients receive individualised treatment and at the same time make the healthcare system more efficient. Personalised medicines are primarily based on modern diagnostics and gene therapy. This trend is impossible without intelligent packaging processes. cannot be realised. In order to be able to fill and package personalised medicines, the packaging systems must be able to handle small batch sizes reliably. The smaller batches require a high degree of flexibility throughout the entire process chain. The industry is pinning its hopes on digital solutions and automation.

Digitalisation as a key technology

Many personalised treatment concepts require a small quantity of a specific drug to be filled in a specific dose - sometimes specifically for one patient. In addition to the task of producing smaller batch sizes efficiently, pharmaceutical companies often have to switch between batches. This increases the importance of process safety and efficiency. This is necessitated by the greater variety of products that Increases the complexity of production. For example, each product must be filled and packaged appropriately and linked to an individual data record.

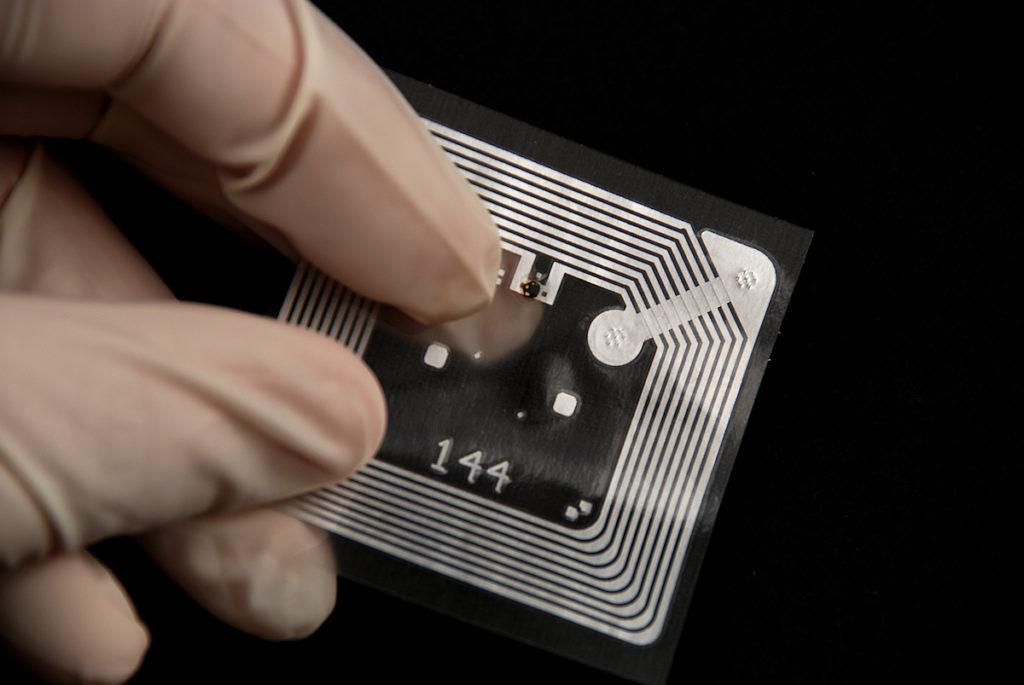

This is done with the help of intelligent packaging, for example. In addition to communication with the end consumer Smart packaging also during the production process Exchange information with the packaging machine. For example, the packaging can use a barcode or a data matrix code to tell the machine which contents are to be inserted.

Safety during production and transport

Personalised medicine could lead to products being delivered directly to the patient. For example, medicines are often packaged in pre-filled syringes or medical devices and designed for personalised administration. These sensitive products, especially biological medicines, require stable temperature and humidity conditions. Shippers must also monitor temperature and humidity using specialised technologies to determine whether the quality of a product has been compromised. As a solution for the Temperature control for example RFID chips that are on or in the packaging. The shipping packaging can also be provided with insulating or cooling properties for active product protection.

Another aspect of personalised medicine that should not be neglected is the Ensuring occupational safety. This is because employee contact with these highly effective substances must be reliably excluded during the filling and packaging process. When working with genetically modified organisms (GMOs), a Closed working environment absolutely necessary.

This aspect plays an important role in the theme park „Packaging in medical technology, pharmacy and chemistry“ will play an important role at FachPack. Personalised products pose greater challenges in terms of production, filling and primary packaging. The special show in Hall 9 will focus, among other things, on how packaging helps with the correct dosing, application and use of active ingredients (compliance).

Automation reduces errors

In response to these requirements, filling and packaging processes are taking centre stage. Automated manufacturing platforms reduce the need for human intervention and increase process and work safety. They also ensure Precise recording and logging of all process steps, which is indispensable in the context of traceability and serialisation.

These concepts also have a decisive influence on the success of the flexibilisation strategy. Pharmaceutical companies are therefore looking for filling and packaging platforms that make it possible to handle different forms of packaging. These range from glass and plastic syringes to vials and applicators. Visitors to FachPack can find out what solutions the industry has to offer at the Guided tour on the topic of pharmaceuticals and medical technology (26 September 2019) or at any time in the Industry compass on the trade fair website.

Source: NürnbergMesse