With the JumboLoadBaler, Strautmann Umwelttechnik is introducing an effective waste disposal solution. The station compacts cardboard, paper, octabins, film, PET bottles and beverage cans and increases production compared to conventional baling presses.

The JumboLoadBaler sets new standards in waste management. Thanks to the use of state-of-the-art technology, the Recyclable material handling reduced, This results in an unprecedented increase in productivity of up to 400 per cent compared to conventional balers.

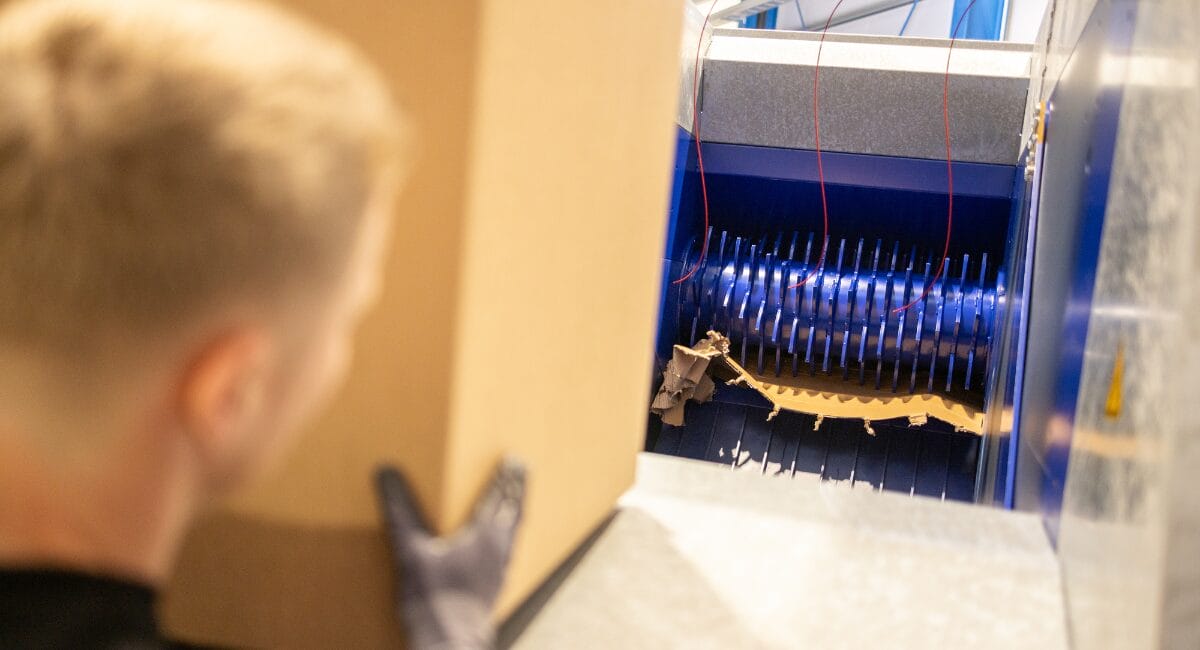

The large feed opening of the press is suitable for feeding in large-volume materials and thus eliminates the need for manual pre-shredding of recyclables. This eliminates time-consuming processes and increases productivity. Thanks to the various filling options using a lifting and tipping device, a conveyor belt, a forklift or a wall connection, the machine can be used in a variety of different ways. easily integrated into existing production processes be. With a throughput of up to two bales per hour, i.e. up to 900 kg of materials, the JumboLoadBaler delivers top performance. The compaction performance results in compact bales of up to 450 kg, which optimise transport and storage.

One feature of the JumboLoadBaler is its ability to optimise the disposal process so that it becomes profitable. The bales produced, measuring 1,000x800x1,000 mm (HxWxD), can be sold directly to waste disposal companies. The increased efficiency of the JumboLoadBaler not only means a considerable cost savings, but also a reduction in the burden on the environment through optimised use of resources. In addition, bales that can be marketed directly not only optimise the Internal space requirement reduced, but also reduces the number of transport journeys required.

„The reduction in travelling times thanks to appropriately sized collection containers and the automatic emptying of these by the tipping device are just some of the advantages. Direct marketing generates consistently positive economic results, even when market prices fluctuate.“

David Frey, Site Manager of Schenker Deutschland AG