Trade fair organiser P. E. Schall, in cooperation with the Baden-Württemberg Mechatronics Network, set a milestone at this year's MOTEK with the Arena of Integration (AoI) special show and demonstrated where the journey in industrial manufacturing processes is heading: digitalisation requires networking, holistic engineering and cooperative project implementation.

A total of 976 exhibitors from 32 countries presented innovations from the fields of production and assembly automation as well as joining and bonding at MOTEK, the International Trade Fair for Production and Assembly Automation, and the International Trade Fair for Bonding Technologies (Bondexpo).

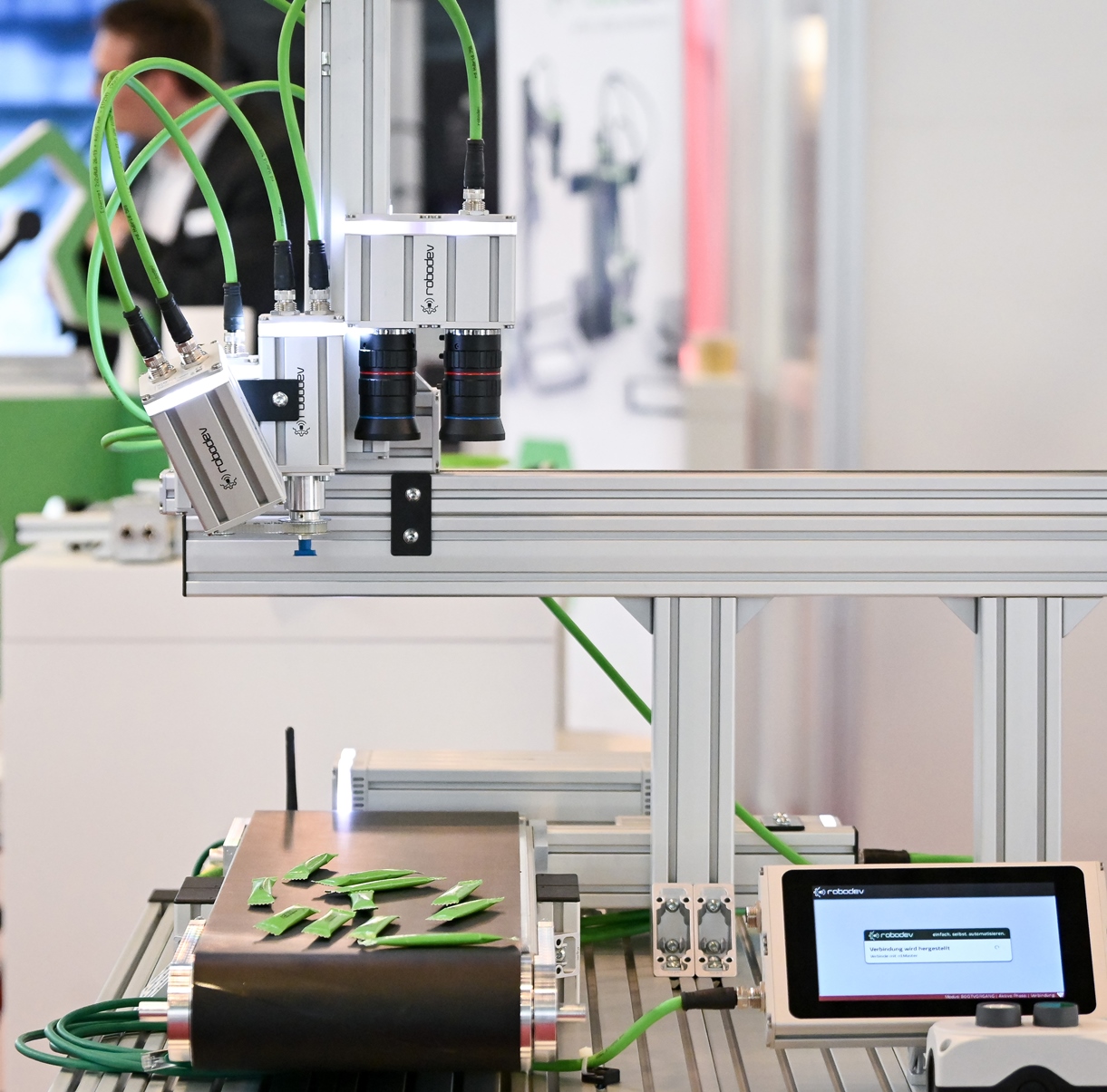

This year's highlight was the integrative theme park AoI with 36 participating companies that provided concrete answers to current questions about intelligent production and process chains in connection with digital applications with 29 networked use cases.

„Really positively surprised by the targeted enquiries“ at the AoI stations, commented Gerald Loser, Head of Sales and Personnel Development at Heldele Mechatronics in Lenningen: „Customers have already made specific enquiries here.“ Philipp Echteler, responsible for digitalisation and IIoT at Balluff, was delighted: „The network here is great.“

[infotext] Developments in the ticker

Innovations for production and assembly automation were presented by B&R. One highlight is the company's vision system, which is seamlessly integrated into the automation system. In combination with the ABB Ability-based Asset Performance Monitor, this enables in-depth quality control in real time, for example. The Asset Performance Monitor also provides a reliable overview of all machines in the field. This is the first time that B&R has launched a cloud application on the market, enabling significantly greater flexibility and efficiency in the processing and packaging of products in complete systems.

The latest sensor and service solutions from a portfolio that covers basic requirements in assembly and handling technology as well as innovative concepts in the implementation of Industry 4.0, for example, were on display at SICK in the bag. A special focus was placed on robotics with the topics of robot guidance, safe robotics and end-of-arm tooling.

More flexibility for ergonomic workstations Bosch Rexroth takes centre stage. The company is strengthening its range in two product categories: the new lifting modules offer compressive forces of 1,000, 1,600 or 3,200 N in three stroke lengths of between 350 and 500 millimetres. This means that even heavy-duty superstructures can be realised at manual workstations. At the same time, the modules open up a wide range of applications thanks to their high tensile forces and stability under lateral forces.

In the modern production environment, sensors also generate valuable data that can be used to significantly improve processes and usability. However, standard sensors on the gripper only recognise the mechanical end stops. With the help of high-precision, measuring inductive sensors from Baumer can generate significant added value here: All states can be precisely scanned. By measuring the jaw position, the gripped workpiece can be checked for dimensional accuracy at the same time.

The Schmersal Group launched the first RFID-based safety sensor in an Ex version on the market this year and presented this new development to the specialist audience. It is designed in accordance with ATEX Directive 2014/34/EU and can be used in Ex zones 2 (gas Ex, category 3G) and 22 (dust Ex, category 3D). The EX-RSS16 thus combines two essential properties for the safety of systems: functional safety in accordance with ISO 13849 and explosion protection. [/infotext]