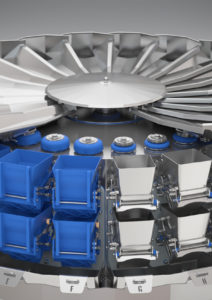

As a special machine manufacturer, Multipond supplies customised weighing systems for fruit and vegetables. The MP-16-3800-2500-J weighing system exhibited at Fruit Logistica 2020 offers customers in the fresh products market maximum performance - hygienic, intelligent and accurate.

Multipond customers fulfil international hygiene regulations

The scales fulfil the highest hygiene requirements worldwide. The complete design of the scale is according to USDA and EHEDG guidelines constructed. Compared to other manufacturers of weighing systems, protection class IP 69 without the generation of overpressure in the machine. No compressed air is required.

With the introduction of the J-generation, the entire machine, from the screws to the frame to the type plate, was designed with Maximum hygiene is taken into account. In principle, all seals are pressed in a defined manner via a metallic stop. All materials that may come into contact with food meet the requirements for food contact materials.

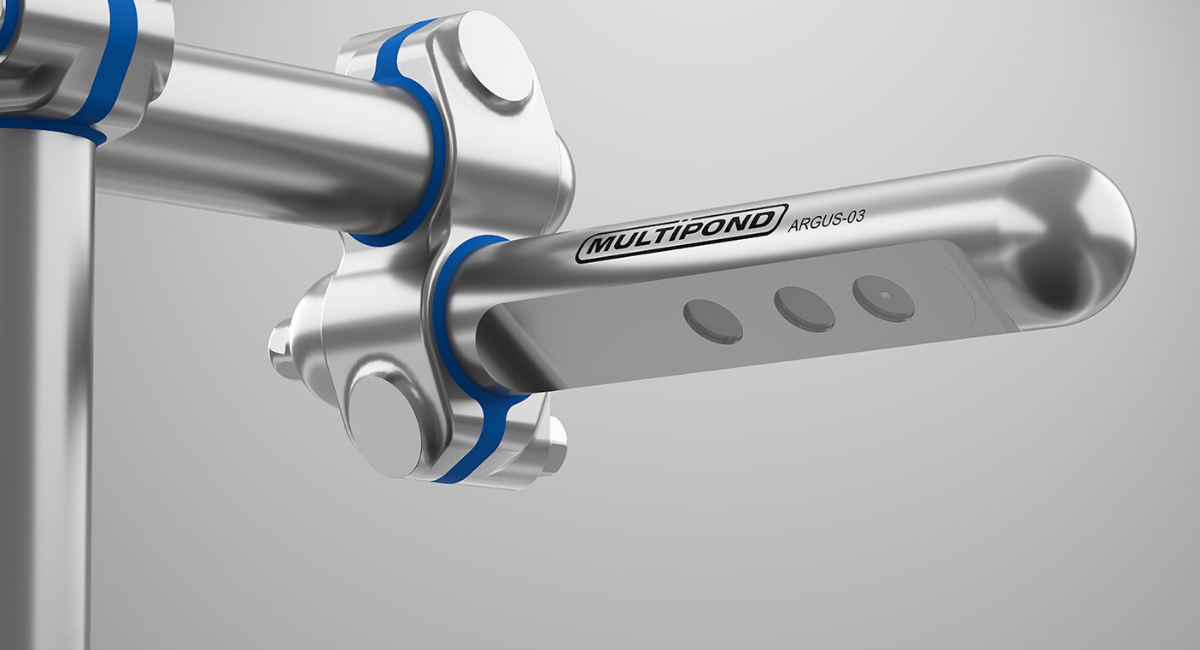

The intelligent camera system - optimised product supply, reduced giveaway

Reliable Information on Multipond customers are provided with a preweigher built into the distribution tray. In addition, the intelligent 3D camera system Further data for controlled filling of the weigher by automatically increasing or reducing the product feed or adjusting the vibration strength of the dosing chutes.

Thanks to the automatic response to the sensor data, the ARGUS guarantees a controlled, Precise filling of the weighing hopper. The optimisation of the product flow has Shorter dosing times and fewer overfills and thus a greater variety of combinations. This leads to higher performance and a reduced giveaway for the customer.

Investing reliably in speed and accuracy

The MP-16-3800-2500-J achieved depending on application, product and nominal filling weight Up to 100 weighings per minute. Distribution discs and dosing chutes are designed with a Multipond stepped profile. This enables a Controlled conveying highly adhesive products. The dosing chute drives are particularly efficient and reliable. The surface profile in combination with a special inclination angle of the dosing chutes are the basis for problem-free and gentle conveying of fresh products and a guarantee for Maximum accuracy and speed.

Multipond at Fruit Logistica 2020: Hall 9, Stand C18