The MULTIVAC Group has achieved a turnover of 1.5 billion euros in 2024. At IFFA in Frankfurt, the company presented new technologies for automation and resource conservation - and announced extensive investments for further growth.

As part of IFFA 2025, the MULTIVAC Group informed at a press conference about its economic development and strategic direction. Despite a challenging economic environment, the company was able to record a stable turnover of 1.5 billion euros in 2024. CEO Christian Traumann explained that the result will enable further growth in line with the strategy and investments in key future areas such as digitalisation, automation and sustainability.

It was also announced that the Group's management will be expanded: From July 2025 Dr Johannes Epple takes over the position of CFO and will be responsible for Corporate Finance, Controlling, Treasury and IT.

„Smart processing and packaging technologies are real competitive factors. They not only help to sustainably optimise machine operation, but also enable agile production - adapted to a constantly changing market.“

(Dr Tobias Richter, CSO Multivac)

New line solutions for automated and efficient food processing

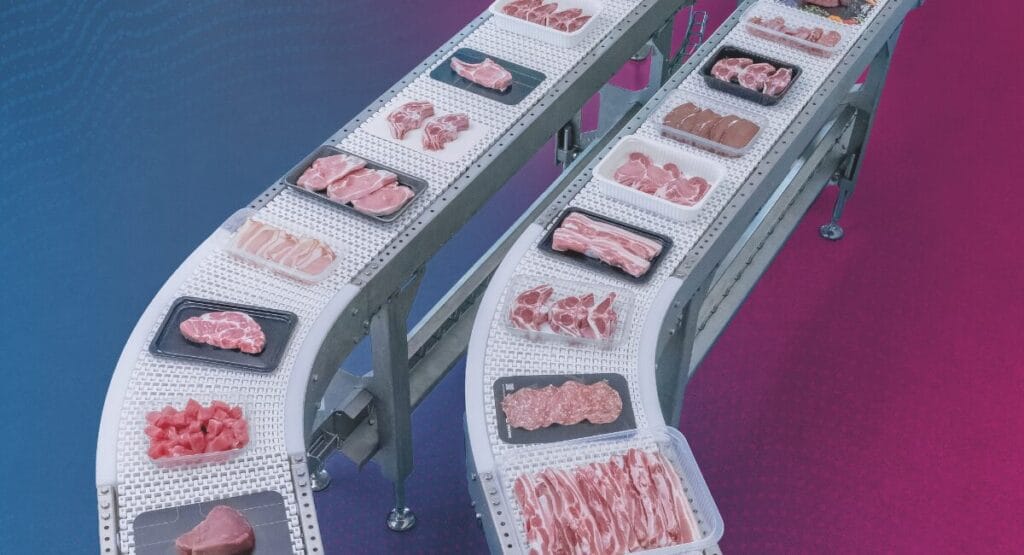

In the trade fair spotlight were fully automated line solutions for meat and protein processing. One highlight is the new high-performance slicing line for raw ham products. It offers end-to-end automation from slicing through infeed and packing to labelling and quality control. Particularly noteworthy is a new function of the MULTIVAC Line Control (MLC), which enables items to be changed continuously during operation - without any interruption to production.

Dr Tobias Richter explained that this makes it possible, „Reduce downtimes by up to 95 per cent“, at the same time as significantly reducing product losses and the consumption of materials and energy.

A new meat portioning line for trays was also presented. Digital networking allows all line components to be controlled and monitored centrally. Live data analysis enables transparent process control. According to Richter, the combination of high portioning accuracy, minimal product loss and maximum labour efficiency sets new standards in the meat portioning industry. „New standards in industrial food production“.

VIDEO

AI-supported vision systems and sustainable production processes

Other trade fair highlights include intelligent vision systems that automatically inspect packs even at high speeds. With the help of AI, they recognise labelling errors, check the pack contents and classify products. Such solutions are intended to help maintain high production quality despite a shortage of skilled labour.

Sustainability remains a central objective: MULTIVAC presented recyclable packaging materials and new packaging designs, which are intended to save material and reduce CO₂ emissions.