Multivac will be presenting innovative solutions for the packaging and labelling of food and pharmaceutical products at Fachpack. The focus is on automation, digitalisation and sustainability.

The trade fair highlights include a packaging line that produces pharmaceutical combination packs from sustainable mono film. This line includes the RX 4.0 thermoforming packaging machine in GMP design, which offers optimum production conditions thanks to a glass enclosure. A SCARA robot takes over the precise, automated loading of the products, which are then printed inline in multiple colours by a digital printer. An optical inspection system carries out a visual print image check.

Product protection through cooling

Sensitive products are protected by a cooled product protection plate, which automatically positions itself between the product and the hot sealing heating plate when the machine is at a standstill. A 6-axis robot then separates the finished packs into good and bad packs and distributes them on various conveyor belts for further process steps.

The RX 4.0 is characterised by high process accuracy and reproducibility, which are ensured by comprehensive sensor technology and continuous process monitoring. RFID-coded moulds monitor permanent format changes and ensure the correct positioning of the moulds. The entire line can be controlled via the packaging machine's user-friendly HMI.

Automated packaging of small batches

Another highlight is the flexible T 305 traysealer, which is ideal for the automated packaging of small to medium-sized batches in the food sector. It is designed for quick product changeovers and can be used in supermarkets, canteen kitchens and industry. The T 305 processes cardboard, plastic and aluminium packs, as well as packs made of foamed materials, and also supports sustainable packaging materials such as mono materials and MULTIVAC PaperBoard. The traysealer guarantees continuous pack output with consistently high quality.

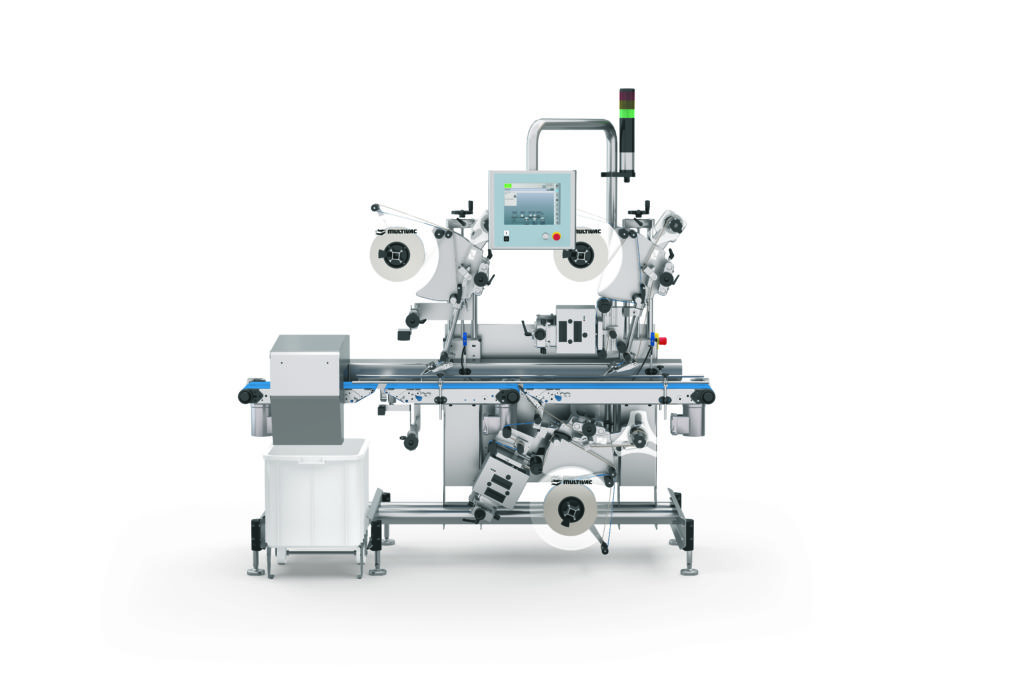

Zero downtime during labelling

MULTIVAC will also be presenting the L 310 conveyor belt labeller, which offers maximum flexibility when labelling trays, thermoformed packs, cartons and other packs. The L 310 can print labels using the required printing technology, apply them to any point on the pack and check them by means of camera inspection. Faulty labels are automatically ejected to ensure that only flawless products reach the market.

Thanks to servo technology, the L 310 achieves maximum speeds and is available as a zero-downtime version, which enables uninterrupted labelling. All modules of the L 310 can be operated via a single terminal, and all parameters are loaded automatically when an article is changed. The labeller can be individually adapted to production requirements and will be demonstrating labelling on the top and bottom of steak trays at the trade fair.

Source: Multivac

More news from Multivac

Women in Packaging: From commercial entry to packaging expert

Automation and sustainability for modern food packaging from Multivac

Multivac packaging line with six-axis kinematics from Yaskawa for the first time

Pet food sustainably packaged