For the first time, Multivac is using a Yaskawa six-axis robot in its new GMP-compliant RX 4.0 thermoforming packaging machine, which is also GMP-compliant.

The growing demands on process accuracy and process reproducibility in the medical goods and pharmaceutical industries when packaging sensitive products have prompted Multivac to develop a thermoforming packaging machine that meets the stricter requirements of customers, the market and legislation. A new feature of the packaging machine is the use of a six-axis robot suitable for the medical and pharmaceutical industry, Multivac is using a third-party brand for the first time.

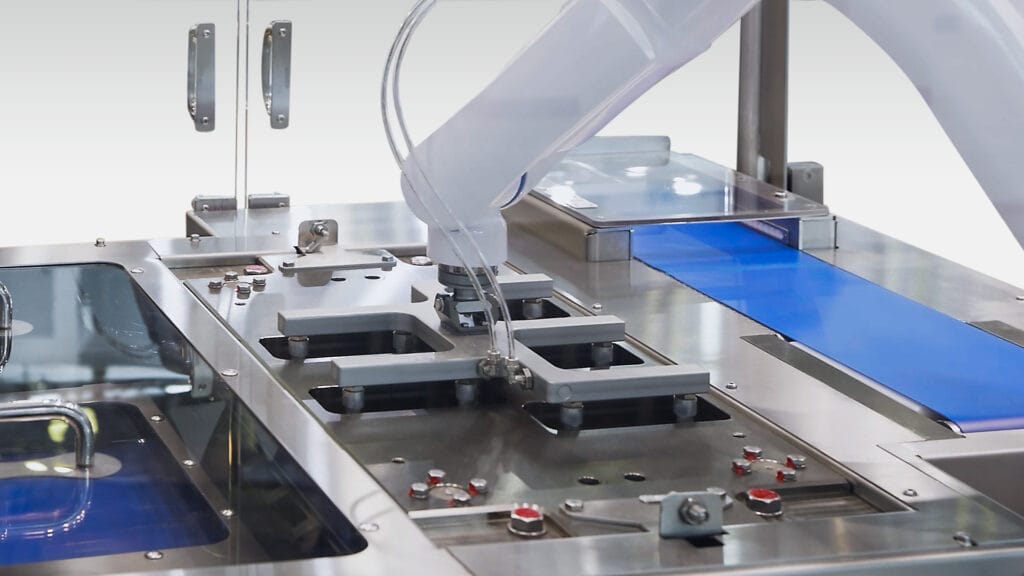

The packaging specialists explain why they favour six-axis kinematics for the new machine. View of how the machine works. The products to be packaged are inserted by a Scara robot, an in-house Multivac development, into thermoformed packaging cavities that the thermoforming packaging machine has formed in the first step. The RX 4.0 takes over the other primary packaging processes, including sealing the bottom film with a top film, which is printed inline in multiple colours before sealing. This is followed by visual print image monitoring and separation of the packs by means of a complete cut.

Six axles provide even more flexibility

At the outlet of the thermoforming packaging machine, the packs are removed directly from the cutting unit and separated by the Yaskawa robot.

„Using the Motoman HD7 has decisive advantages, especially in terms of flexibility. We can unload on the basis of single or multiple picks; in our demo system, for example, we have a five-fold vacuum gripper in use. The packs can also be separated onto moving conveyor belts or into defined stationary positions. And thanks to the six axes, we have no restrictions when it comes to the accessibility of positions and can handle many different formats.“

Wolfgang Buchenberg, Senior Director Technics Solutions at Multivac

Design that offers decisive advantages in the pharmaceutical and medical sectors. (Image: Yaskawa)

A European development for cleanrooms of all kinds

The Motoman HD7 from the Japanese manufacturer Yaskawa is a new European development for sensitive applications, developed in close cooperation with the Fraunhofer Institute for Manufacturing Engineering and Automation IPA. The HD7, like its bigger brother the HD8, is suitable for use in cleanrooms of class ISO 5 up to the highest GMP class A. But the GMP-compliant and cleanroom-compatible design was only one aspect that influenced the decision in favour of Yaskawa. Wolfgang Buchenberg comments: „For us, the topic of ‚control technology and integration‘ is also of decisive importance. Yaskawa's ‚MotoLogix‘ software interface enables Motoman kinematics, including cobots, to be seamlessly integrated into Multivac's control and software platform, This ensures centralised line operation from a single source, even for six-axis robots.“

The Yaskawa HD series also convinces with their reduced kinematics design, which offers decisive advantages in the pharmaceutical and medical sectors. The routing of cables and connections within the arm, low particle formation and FDA conformity ensure the necessary customer acceptance and facilitate key requirements such as simple line clearance.

With the new RX 4.0 thermoforming packaging machine and the first-time integration of a Yaskawa six-axis machine, the company has succeeded in launching a customised solution for the pharmaceutical and medical sector, which can be used in a wide range of applications. equally suitable for applications in primary, secondary and tertiary packaging. Sterile medical products such as implants, catheters, suture material, needles and pharmaceutical syringes, vials, ampoules, pens, injectors and combinations thereof can be packaged reliably, economically and sustainably in small and large production batches with the RX 4.0.

SourceYaskawa