With smart motion solutions for automated production, Getriebebau Nord GmbH & Co. KG, Member of the Nord Drivesystems Group, Bargteheide, will be showcasing smart motion solutions for automated production. The focus will be on multivariable drive electronics, the effective NXD tupH surface protection system and digital Nord services ranging from virtual commissioning to predictive maintenance.

The frequency inverters of the various product families can be used flexibly in any system architecture: They can be installed both in the control cabinet and in the field, directly motor-mounted or mounted close to the motor. They also support all common Ethernet protocols, in some cases via multi-protocol Ethernet interfaces. The company will also be presenting the drive-based functional safety of its drive electronics, which include local safety-related sensors and actuators such as emergency stops or safety light grids.

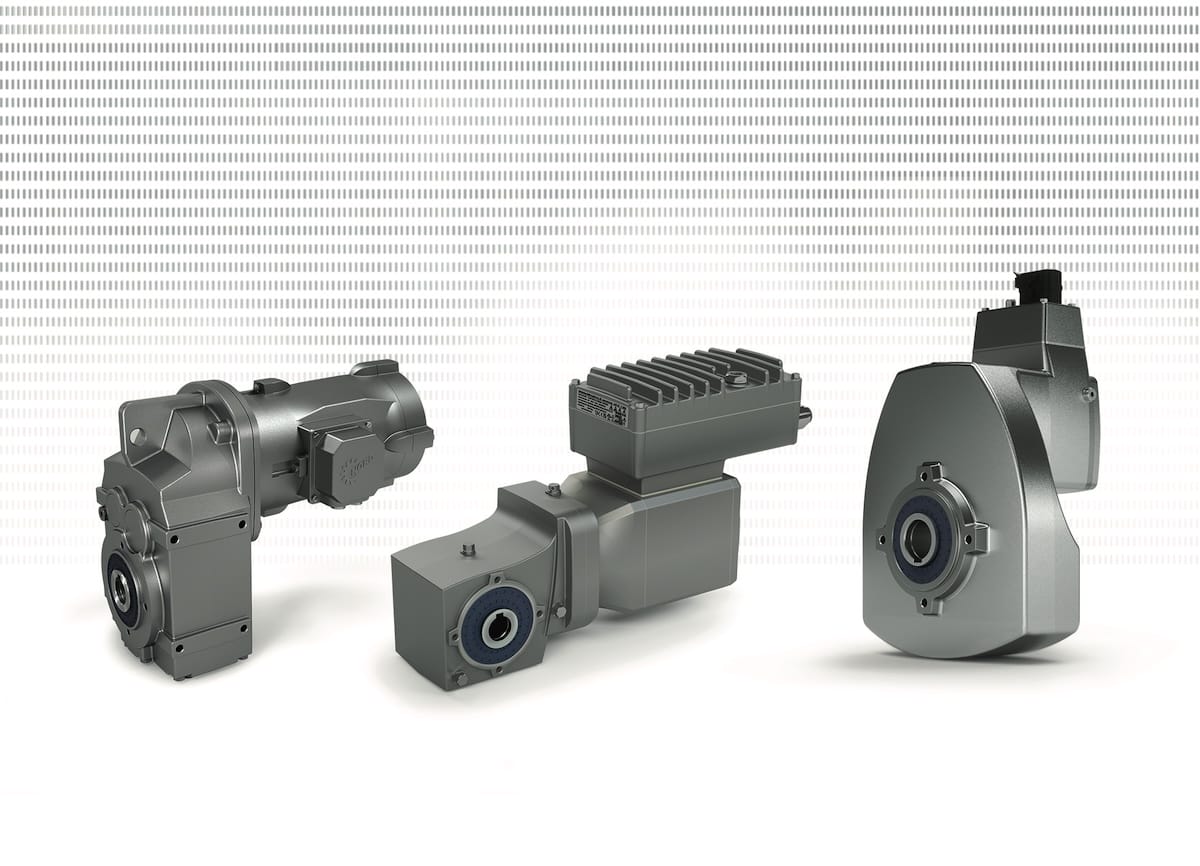

During a live demonstration, visitors can see for themselves the effectiveness of the special surface protection for the extreme conditions in wash-down areas (image). It makes aluminium housings resistant to acids and alkalis. The basis is a finish that creates a very hard, inert surface.

Another topic on site: the data-based services with which the solution provider enables the optimum performance of its drive systems in every phase of the life cycle. The simulation models for the virtual commissioning of components will be presented for the first time as a new service for the planning phase. The digital twins can be comprehensively tested in a simulated system and errors can be corrected at an early stage of development. Once the drive system has been validated by the customer, it is manufactured. The fact that the drives are then already functionally integrated into the system control accelerates real commissioning.

Nord Drivesystems at the sps: Hall 3A, Stand 431