Following a test phase at four pilot locations, the Nagel-Group has now switched its loading equipment management to the software solution from the start-up Logistikbude at all 130 locations.

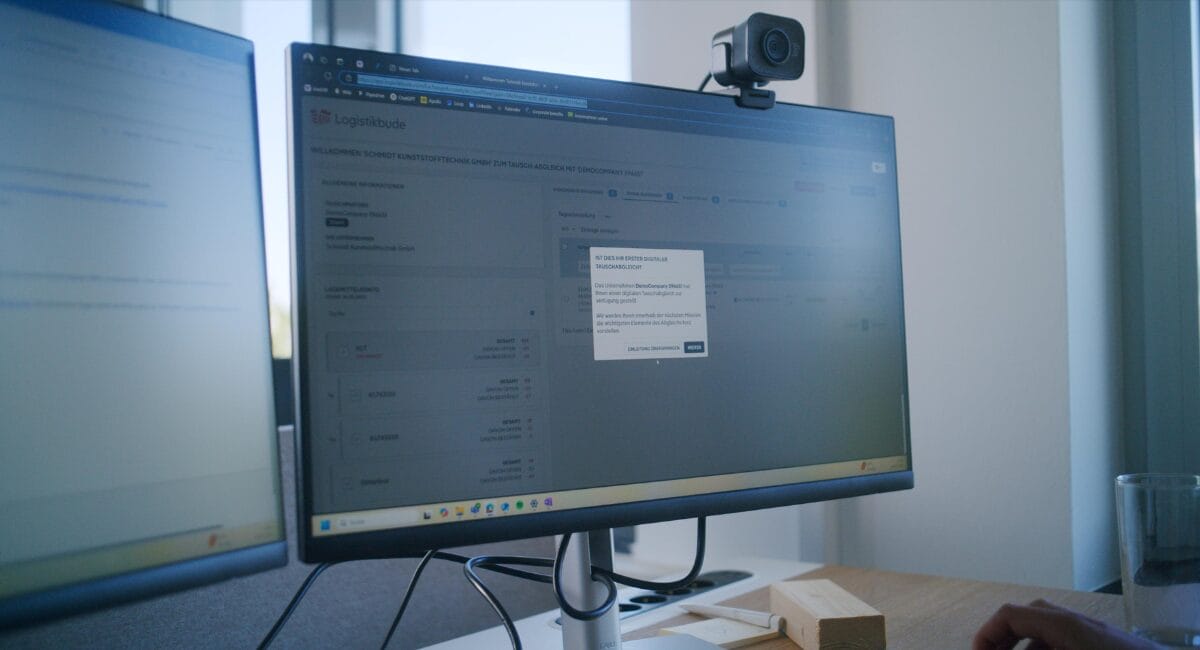

The aim of the Nagel-Group's digitalisation initiative was to digitally manage returnable goods management („loading aids“) throughout the company using the SaaS solution from Logistikbude. The start-up offers a Solution for digitally networked and automated management of all loading equipment, from Euro pallets to plastic pallets and Euro boxes, in real time, thereby leveraging considerable optimisation potential in terms of processes, costs and sustainability.

The Nagel-Group moves around 25 million Euro pallets, 35 million Euro boxes and three million H1 plastic pallets per year and, like most logistics service providers, faces the major challenge of maintaining an overview of current stocks and the whereabouts of exchanged load carriers. Logistikbude utilises existing data for the newly designed load carrier management system. Important information on the whereabouts of the load carriers can be obtained from numerous existing upstream systems.

The key users at the locations were intensively trained for the successful go-live. The software will continue to be developed even after the launch. New functions and process optimisations are being introduced step by step. Practical experience and feedback from users are incorporated directly. In this way, the system remains closely aligned with actual needs.

The next step is to add a function to the software solution, which automatically analyses various pallet notes on the basis of artificial intelligence and book. Thanks to real-time recording and management using the software, every load carrier is digitally visible at all times. This means that even exchange partners who have not implemented the software can view all the data on the crates and pallets via a web link. If several parties make full use of the solution, load carrier management runs almost automatically.

Complete documentation increases the Security in the supply chain. This also has a positive financial impact: fewer shortfalls lead to a lower repurchase rate and thus to a lower capital commitment.

Source: Logistics centre