The combination of new technologies from Bobst is intended to offer folding carton manufacturers greater flexibility and efficiency. This is made possible by more automation and digitalisation in the die-cutting process.

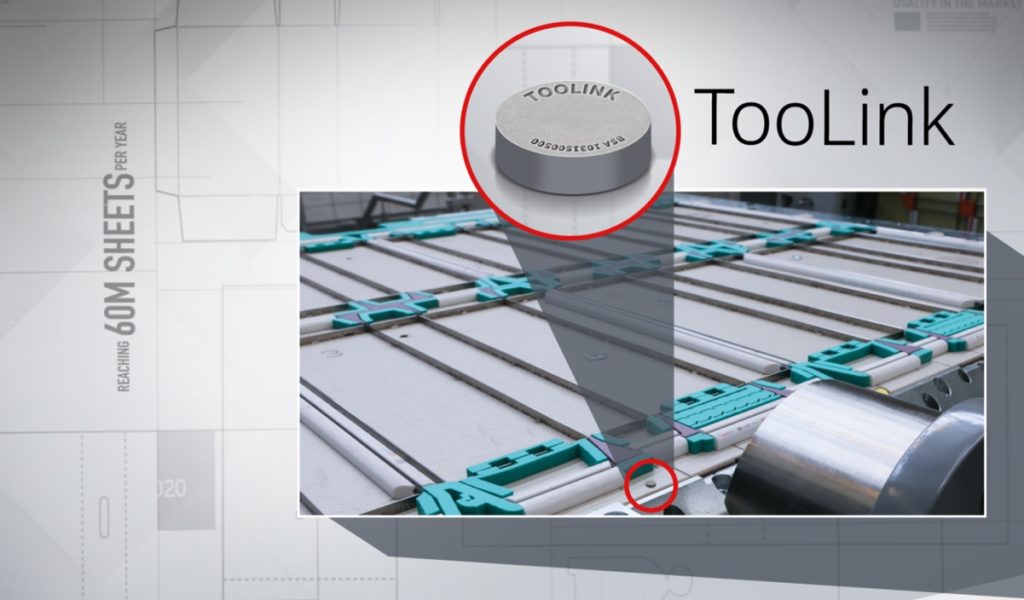

In June 2020, Bobst TooLink a digital tool for managing the specifications for tool production for the die-cutting process. In conjunction with TooLink, the MASTERCUT 106 PER flatbed die-cutter embodies Bobst's vision for the future. Here the entire value chain of packaging production networked be.

„Here, machines and moulds communicate with each other to enable the highest quality and performance while reducing errors, waste and costs in all process steps. By launching new intelligent systems such as the cloud-based workflow platform Bobst Connect and TooLink, we are raising the level of automation of production sites and machines to an unprecedented level.“ Bodo Junge, Product Marketing Director Folding Carton at Bobst

The MASTERCUT 106 PER is characterised by additional production options. Its automated functions from ‚feeder to delivery‘ can be set and controlled centrally from a single point. This minimises the number of operator interventions during operation.

Furthermore, the setting of the stripping and blanking tools is completely automated. The cameras of the Matic-Plus system measure the positions of the tools. They automatically align them to the printed sheets in register. The settings for jam detection and non-stop raking in the delivery are also automated.

All this makes it possible to Set-up times reduced by up to 15 minutes in the punching process. The die-cutting machine is therefore suitable for the production of both small and large runs. „Packaging manufacturers can therefore accept all types of orders, regardless of their size,“ says Junge.

Increase productivity in the punching process

The TooLink platform is integrated into the MASTERCUT 106 PER. This connects the punching machine with tool production and brings the entire process together. This technology increases flexibility in production and order processing. At the same time, it increases productivity in the punching process.

With TooLink, tools equipped with chips and the job data stored on them are automatically recognised by the die-cutters using digital IDs and aligned in the machines. This reduces waste in the punching process. Repeat jobs can be called up automatically without operator intervention.

„With TooLink and our IoT applications, we are giving packaging manufacturers a complete overview about their punching tools, the specifications for tool production and their order history. We also give them access to a higher level of production data. This gives them additional insights into their punching process.“ Alex Volery, Head of Tooling Division at Bobst.

SourceBOBST