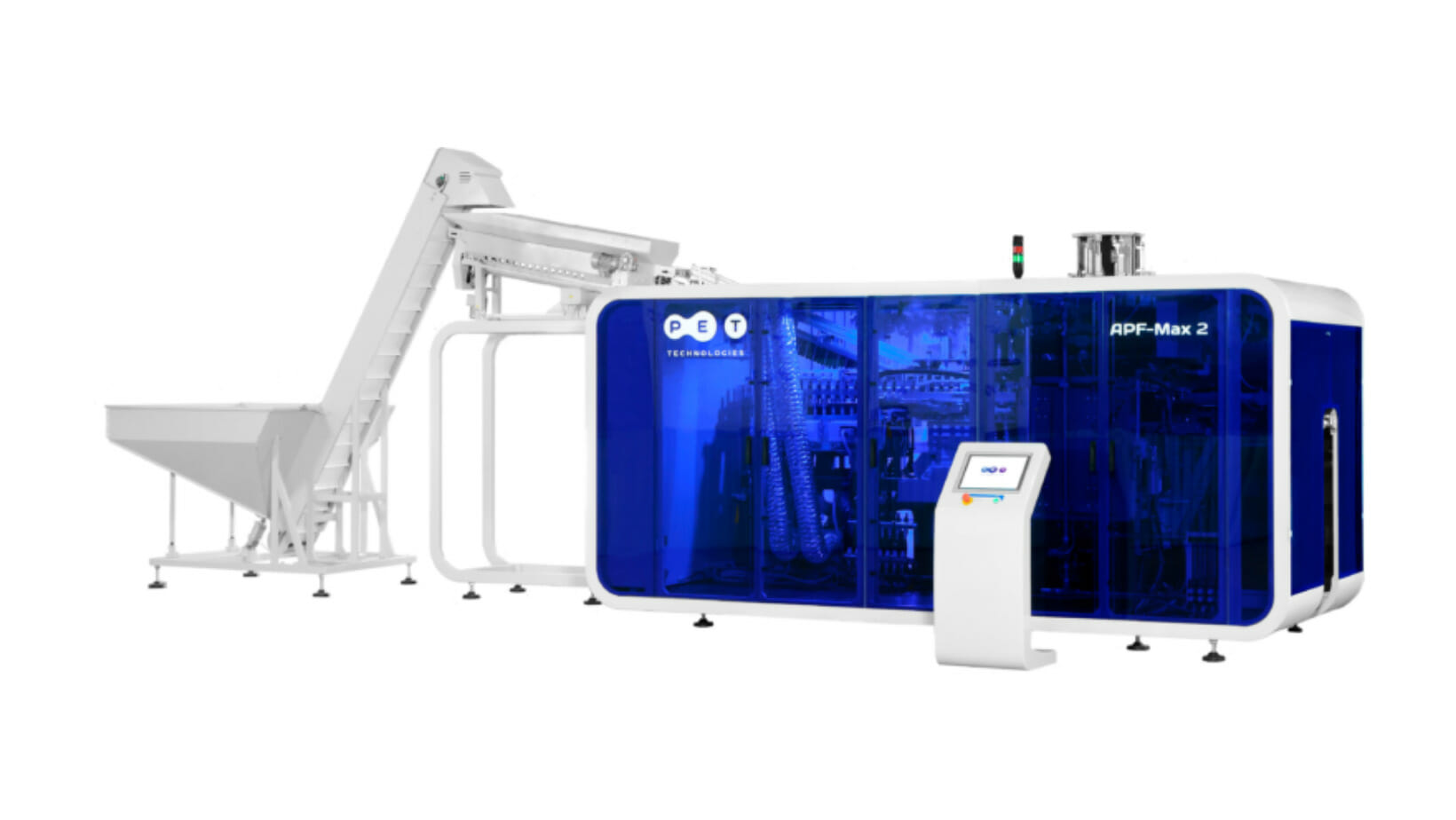

PET Technologies will be presenting its latest blow-moulding machine for the production of PET bottles at BrauBeviale 2023. It is a solution for anyone who either wants to start production or switch from semi-automatic machines to higher productivity with a linear machine.

The APF-Max 2 is a two-cavity machine from the APF-Max series of blow moulding machines designed for the production of PET bottles with a volume of 0.2 to 2.25 litres and an output of up to 3,500 bottles per hour is designed. The blow moulding machine has a number of features that set it apart from other similar machines. In particular, it offers quick changeover options that allow the transition between preform types from 18 to 38 mm with ease.

To ensure precision and consistent quality during the moulding process, each mould cavity is equipped with a series of valves. The patented moulded closing system and the machine's automatic temperature control also contribute to its efficiency and reliability, making the APF-Max 2 a good choice for modern production requirements.

One of the main features of the APF-Max 2 is the NIR heating system for preforms. PET Technologies was one of the first companies to adapt NIR heating to linear PET stretch blow moulding machines. The innovative APF-Max blow moulding machine series is one of the first SBM machines of the linear type to use this system!

The Advantages of the NIR heating system for PET bottle productionEven temperature distribution between the inner and outer parts of the preform wall, reduced heating time, compact size of the heater and lower energy consumption of the blow moulding machine.

The heating process is faster compared to a conventional infrared (IR) system. This Reduces energy consumption and enables the construction of a smaller (shorter) heater of the APF-Max 2. The system has a smaller footprint and is easier to transport.

PET Technologies is involved in many areas of PET bottle production, one of which is the manufacture of blow moulds. The company manufactures moulds for all European brands of rotary and linear blow-moulding machines using Duralumin alloys of German origin. These alloys have an exceptional hardness that reaches up to 100HB. This particular type of aluminium has unique mechanical properties and offers an optimal balance between hardness and plasticity, making it ideal for withstanding impact loads.

Source: PET Technologies

PET Technologies at the BrauBeviale 2023: Hall 7, Stand 646

BrauBeviale - More news

dvi at the BrauBeviale

Packaging lines for beer and beverages

Efficient labelling for beverages

Sustainability and safety for closures

Recyclable closures for the beverage industry